Abstract

Purpose

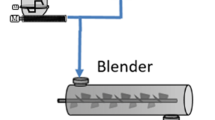

This paper presents a real-time process management (RTPM) strategy for Dropwise Additive Manufacturing of Pharmaceutical Products (DAMPP), a mini-manufacturing method for pharmaceutical dosage forms. The semicontinuous, small-scale nature of DAMPP allows for more automation and control than traditional large-scale batch pharmaceutical manufacturing processes and can be used to manufacturing drug products with precise amounts of active pharmaceutical ingredients (API), suitable for production of high-potency drug products or individualized medicine.

Methods

The RTPM strategy for DAMPP consists of advanced process control to ensure that every dosage unit meets quality specifications. We use temperature control systems and an imaging system linked to a LabVIEW automation program.

Results

The system is successful in controlling deposition of both solvent-based and melt-based dosage forms. It controls process and product temperature and monitors each drop visually. It records data pertinent to each deposited drop, determines the drop volume and thus API amount deposited, and automatically detects and diagnoses process faults.

Conclusions

With a proper automation, control, and monitoring strategy, DAMPP is a viable manufacturing method for pharmaceutical dosage forms.

Similar content being viewed by others

References

Rowe R C, Roberts R J. “Expert systems in pharmaceutical product development”. Encycl Pharm Technol Inform Healthcare. (2006); 1663–84.

Balboni ML. Process analytical technology: concepts and principles. Pharm Technol. 2003;27(254):54–66.

Tyson TC. Pharmaceutical manufacturing innovation. J Pharm Innov. 2007;2(1–2):37.

Lawrence XY. Pharmaceutical quality by design: product and process development, understanding, and control. Pharm Res. 2008;25(4):781–91.

Hirshfield L, Giridhar A, Taylor LS, Harris MT, Reklaitis GV. Dropwise additive manufacturing of pharmaceutical products for solvent-based dosage forms. J Pharm Sci. 2014;103(2):496–506.

Icten E, Giridhar A, Taylor LS, Nagy ZK, Reklaitis GV. Dropwise additive manufacturing of pharmaceutical products for melt-based dosage forms. J Pharm Sci. 2015. doi:10.1002/jps.24367.

Perelaer J, Krober P, Delaney J T, Schubert U S. Fabrication of two and three-dimensional structures by using inkjet printing. NIP25 Digit Fabr. 2009; 791–4.

Khalate AA, Bombois X, Babuˇ R. Performance improvement of a drop-on-demand inkjet printhead using an optimization-based feedforward control method. Control Eng Pract. 2011;9(19):771–81.

Calvert P. Inkjet printing for materials and devices. Chem Mater. 2001;13(10):3299–305.

de Gans B-J, Duineveld PC, Schubert US. Inkjet printing of polymers: state of the art and future development. Adv Mater. 2004;16(3):203–13.

Pierik A, Dijksman F, Raaijmakers A, Wismans T, Stapert H. Quality control of inkjet technology for DNA microarray fabrication. Biotechnol J. 2008;3(12):1581–90.

De Beer T, Burggraeve A, Fonteyne M, Saerens L, Remon JP, Vervaet C. Near infrared and Raman spectroscopy for the in-process monitoring of pharmaceutical production processes. Int J Pharm. 2011;417(1–2):32–47.

Trasi NS, Taylor LS. Effect of polymers on nucleation and crystal growth of amorphous acetaminophen. CrystEngComm. 2012;14(16):5188.

Dong HM, Carr WW, Morris JF. An experimental study of drop-on-demand drop formation. Phys Fluids. 2006;18(7):16.

Icten E, Nagy Z K, Reklaitis G V. Supervisory control of a drop on demand mini-manufacturing system for pharmaceuticals. In: 24th European Symposium on Computer-Aided Process Engineering, Computer-Aided Chemical Engineering, 2014. pp. 535–40.

Fujiwara M, Nagy ZK, Chew JW, Braatz RD. First-principles and direct design approaches for the control of pharmaceutical crystallization. J Process Control. 2005;15(5):493–504.

Hugli H, Gonzalez J. Drop volume measurements by vision. Imaging. 2000;3966:60–6.

Keyence.: Machine vision academy: master the latest vision techniques (2009). [Online]. Available: www.keyence.com/rss/vision/cv/academy11.php. Accessed 03 Apr 2012.

Clarke A J, Fiesser F H, McHugh J A. “Vapor sheath for liquid dispensing nozzle”. 2011.

Acknowledgments

This work was completed with the support from the National Science Foundation Engineering Research Center for Structured Organic Particulate Systems (EEC-0540855). We would like to thank Indiana Next Generation Manufacturing Competitiveness Center (IN-MaC) for the financial support provided to E.I. We are grateful for the advice and counsel of Fritz Fiesser of GlaxoSmithKline on a range of technical implementation issues.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hirshfield, L., Içten, E., Giridhar, A. et al. Real-Time Process Management Strategy for Dropwise Additive Manufacturing of Pharmaceutical Products. J Pharm Innov 10, 140–155 (2015). https://doi.org/10.1007/s12247-015-9218-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-015-9218-5