Abstract

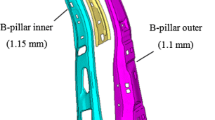

This study compares the optimum designs of center pillar assembly with advanced high-strength steel (AHSS) to that of conventional steel for crashworthiness and weight reduction in side impacts. A simplified side impact analysis method was used to simulate the crash behavior of the center pillar assembly with efficient computing time. Thickness optimization aims to perform an S-shaped deformation of the center pillar toward the cabin to reduce the injury level of a driver in a crash test. Center pillar members were regarded as an assembly of parts that are fabricated with tailor-welded blanks, and the thickness of each part was selected as a design variable. The thickness variables of parts that have significant effects on the deformation mechanism were extracted as the main design variables for thickness optimization based on the results of a sensitivity analysis with design of experiments. The optimization condition was constructed to induce an S-shaped deformation mode and reduce the weight of the center pillar assembly. An optimum design was obtained after several iterations with response surface methodology (RSM). Optimization was first performed with conventional steel and then with AHSS with the same procedure to optimize the crashworthiness of the center pillar assembly. After thickness optimization, optimum designs were applied to the full vehicle analysis to evaluate the validity of the optimization scheme with the simplified side impact analysis method. Then, the crashworthiness of optimum designs with conventional steel and AHSS were compared using the full vehicle analysis. This comparison demonstrates that AHSS can be more effectively utilized than conventional steel to obtain a lightweight design of an auto-body with enhanced crashworthiness.

Similar content being viewed by others

References

Bae, G. H., Song, J. H., Huh, H. and Kim, S. H. (2005). Optimum design of a center-pillar model with a simplified center-side impact analysis. Trans. Korean Society of Automotive Engineers 13,6, 84–92.

Bae, G. H., Song, J. H., Huh, H. and Kim, S. H. (2006). Light-weight design with a simplified center-pillar model for improved crashworthiness. Trans. Korean Society of Automotive Engineers 14,6, 1–8.

Bae, G. H. and Huh, H. (2008). Regression model for light weight and crashworthiness enhancement design of automotive parts in frontal car crash. Int. J. Modern Physics B 22,31/32, 5584–5589.

Elmarakbi, A. M. and Zu, J. W. (2005). Crashworthiness improvement of vehicle-to-rigid fixed barrier in full frontal impact using novel vehicle’s front-end structures. Int. J. Automotive Technology 6,5, 491–499.

Huh, H., Lim, J. H., Song, J. H., Lee, K. S., Lee, Y. W. and Han, S. S. (2003). Crashworthiness assessment of side impact of an auto-body with 60trip steel for side members. Int. J. Automotive Technology 4,3, 149–156.

IIHS (2004). IIHS Side Impact Test Program Rating Guidelines. IIHS. Washington DC.

Kurtaran, H., Eskandarian, A., Marzougui, D. and Bedewi, N. E. (2002). Crashworthiness design optimization using successive response surface approximations. Computational Mechanics, 29, 409–421.

Marklund, P. O. and Nilsson, L. (2001). Optimization of a car body component subjected to side impact. Struct. Multidisc. Optim., 21, 383–392.

Montgomery, D. (2001). Design and Analysis of Experiments. 5th Edn. John Wiley & Sons. New York. 427–500.

Oh, S., Ye, B.-W. and Sin, H.-C. (2007). Size optimization of an engine room member for crashworthiness using response surface method. Int. J. Automotive Technology 8,1, 93–102.

Yamazaki, K. and Han, J. (2000). Maximization of the crushing energy absorption of cylindrical shells. Advances in Engineering Software, 31, 425–434.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bae, G.H., Huh, H. Comparison of the optimum designs of center pillar assembly of an auto-body between conventional steel and ahss with a simplified side impact analysis. Int.J Automot. Technol. 13, 205–213 (2012). https://doi.org/10.1007/s12239-012-0017-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-012-0017-4