Abstract

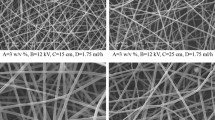

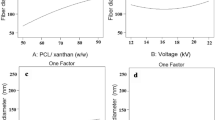

Biodegradable edible sub-micron electrospun zein fibers were prepared using acetic acid as solvent. The solution concentration at three levels: 22, 26 and 30 w/v %, the electrospinning voltage at three levels: 10, 20 and 30 kV, the solution flow rate at three levels: 4, 8 and 12 ml/h and the distance between needle tip and collector at three levels: 10, 15 and 20 cm were studied. Central composite design (CCD) was utilized to modeling the effect of electrospinning parameters of zein solution on average fiber diameters and the data were analyzed using response surface methodology (RSM). Coefficient of determination, R2, of fitted regression model was higher than 0.9 for response. The analysis of variance table showed that the lack of fit was not significant for response surface model at 95 %. Therefore, the model for response variable was highly adequate. Results also indicated that the solution concentration had significant influence (P<0.0001) on morphology and diameter of fibers. By increasing the solution concentration, uniform and bead-free fibers were obtained. As the solution concentration was increased, the average fiber diameters were also increased. Furthermore, the electrospinning voltage had significant effect (P<0.0001) on average fiber diameters. By increasing the electrospinning voltage, the average fiber diameters increased. The solution flow rate and the distance between needle tip and collector had no significant influence on the average fiber diameters. According to model optimization, the minimum average fiber diameter of electrospun zein fiber is given by following conditions: 24 w/v % zein concentration, 10 kV of the applied voltage, 10 cm of needle tip to collector distance, and 4 ml/h of solution flow rate.

Similar content being viewed by others

References

R. Shukla and M. Cheryan, Ind. Crop. Prod., 13, 171 (2001).

Y. P. Neo, Ph. D. Dissertation, UOA, New Zealand, 2013.

S. Torres-Giner, E. Gimenez, and J. M. Lagaron, Food. Hydrocolloid., 22, 601 (2008).

W. Huang, T. Zou, S. Li, J. Jing, X. Xia, and X. Liu, Aaps. Pharmscitech., 14, 675 (2013).

N. Bhardwaj and S. C. Kundu, Biotechnol. Adv., 28, 325 (2010).

Z. M. Huang, Y. Z. Zhang, M. Kotaki, and S. Ramakrishna, Compos. Sci. Technol., 63, 2223 (2003).

S. Alborzi, Ph. D. Dissertation, UOA, Ontario, 2012.

C. J. Angammana, Ph. D. Dissertation, UW, Ontario, 2011.

B. Ghorani and N. Tucker, Food. Hydrocolloid., 51, 227 (2015).

C. A. Fuenmayor, E. Mascheroni, M. S. Cosio, L. Piergiovanni, S. Benedetti, M. Ortenzi, A. Schiraldi, and S. Mannino, Chem. Eng. Trans., 32, 1771 (2013).

Y. Li, L. T. Lim, and Y. Kakuda, J. Food. Sci., 74, C233 (2009).

S. Agarwal, J. H. Wendorff, and A. Greiner, Polymer, 49, 5603 (2008).

E. R. Kenawy, F. I. Abdel-Hay, M. H. El-Newehy, and G. E. Wnek, Mater. Chem. Phys., 113, 296 (2009).

X. Zong, K. Kim, D. Fang, S. Ran, B. S. Hsiao, and B. Chu, Polymer, 43, 4403 (2002).

C. Kriegel, A. Arrechi, K. Kit, D. J. McClements, and J. Weiss, Crit. Rev. Food. Sci., 48, 775 (2008).

N. Sozer and J. L. Kokini, Trends. Biotechnol., 27, 82 (2009).

A. López-Rubio and J. M. Lagaron, Innov. Food. Sci. Emerg., 13, 200 (2012).

S. Wongsasulak, M. Patapeejumruswong, J. Weiss, P. Supaphol, and T. Yoovidhya, J. Food Eng., 98, 370 (2010).

G. W. Selling, A. Biswas, A. Patel, D. J. Walls, C. Dunlap, and Y. Wei, Macromol. Chem. Phys., 208, 1002 (2007).

Y. Wang and L. Chen, Macromol. Mater. Eng., 297, 902 (2012).

T. Miyoshi, K. Toyohara, and H. Minematsu, Polym. Int., 54, 1187 (2005).

C. Yao, X. Li, and T. Song, J. Appl. Polym. Sci., 103, 380 (2007).

S. Ramakrishna, K. Fujihara, W.-E. Teo, T.-C. Lim, and Z. Ma, “An Introduction to Electrospinning and Nanofibers”, 1st ed., pp.92–114, World Scientific Publishing Co. Pte. Ltd., Singapore, 2005.

S. Koombhongse, W. Liu, and D. H. Reneker, J. Polym. Sci. Pol. Phys., 39, 2598 (2001).

H. Jiang, P. Zhao, and K. Zhu, Macromol. Biosci., 7, 517 (2007).

M. K. M. Essalhi, C. Cojocaru, M. C. García-Payo, and P. Arribas, Tonanoj, 7, 8 (2013).

V. Beachley and X. Wen, Mat. Sci. Eng. C-Mater., 3, 663 (2011).

S. H. Tan, R. Inai, M. Kotaki, and S. Ramakrishna, Polymer, 46, 6128 (2005).

J. S. Lee, K. H. Choi, H. D. Ghim, S. S. Kim, D. H. Chun, H. Y. Kim, and W. S. Lyoo, J. Appl. Polym. Sci., 93, 1638 (2004).

M. Hasanzadeh, B. Hadavi Moghadam, M. H. Moghadam Abatari, and A. K. Haghi, Bulg. Chem. Commun., 45, 178 (2013).

C. Zhang, X. Yuan, L. Wu, Y. Han, and J. Sheng, Eur. Polym. J., 41, 423 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miri, M.A., Movaffagh, J., Najafi, M.B.H. et al. Optimization of elecrospinning process of zein using central composite design. Fibers Polym 17, 769–777 (2016). https://doi.org/10.1007/s12221-016-6064-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-016-6064-0