Abstract

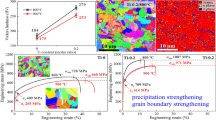

Rare earth metals can create a fine eutectic Si structure in cast Al-Si10.6-Cu2.5 (ADC12) alloys produced through heated mold continuous casting. Fine and spherical eutectic Si phases are created in the ADC12 alloys through the addition of Sr0.04, and fine lamellar eutectic Si phases are created through Sb and Bi addition. Crystal orientation on the face perpendicular to the casting direction is formed by [110]; however, this uniform formation is collapsed in the ADC12 alloy with an increasing amount of Sr addition, such as Sr > 0.04%. The shape of the eutectic Si is statically analyzed, and the effects of the eutectic Si characteristics on the mechanical properties are examined experimentally. On the one hand, the mechanical properties of the ADC12-Sr alloy increase with increasing Sr content because of the fine eutectic Si, the randomly orientated crystal formation, and so on. On the other hand, the material ductility increases in the ADC12 alloy with increasing addition of Sb and Bi elements. A high fracture strain of approximately 14% is obtained for the ADC12-Bi1.5 alloy.

Similar content being viewed by others

References

M. Okayasu, S. Takasu and M. Mizuno, Relevance of instrumented nano-indentation for the assessment of the mechanical properties of eutectic crystals and a—Al grain in cast aluminum alloys, J. Mater. Sci., 47 (2012) 241–250.

M. Zarif, B. Mckay and P. Schumacher, Study of heterogeneous nucleation of eutectic Si in high-purity Al-Si alloys with Sr addition, Matell. Mater. Trans. A, 42A (2011) 1684–1691.

A. Pacz, U.S. Patent No.1, 387 900 (1921).

Z. Yin, Q. Pan, Y. Zhang and F. Jiang, Effect of minor Sc and Zr on the microstructure and mechanical properties of Al-Mg based alloys, Mater. Sci. Eng. A, 280 (2000) 151–155.

C. M. Dinnis, M. O. Otte, A. K. Dahle and J. A. Taylor, The influence of strontium on porosity formation in Al-Si alloys, Metall. Mater. Trans. A, 35 (2004) 3531–3541.

H. Nalae, K. Song and H. Fujii, New application of unidirectional solidification method for observation of interfacial morphology, Mater. Trans. JIM, 33 (1992) 1051–1056.

J. Chang, I. Moon and C. Choi, Refinement of cast microstructure of hypereutectic Al-Si alloys through the addition of rare earth metals, J. Mater. Sci., 33 (1998) 5015–5023.

S. Farahany, M. H. Idris and A. Ourdjini, Evaluations of antimony and strontium interaction in an Al-Si-Cu-Zn die cast alloy, Therm. Acta., 584 (2014) 72–78.

Y. Chen, Y. Pan, T. Lu, S. Tao and J. Wu, Effects of combinative addition of lanthanum and boron on grain refinement of Al-Si casting alloys, Mater. Des., 64 (2014) 423–426.

H. Soda, G. Motoyasu, A. Mclean, C. K. Jen and O. Lisbôa, Method for continuous casting of metal wire and tube containing optical fibre, Mater. Sci. T., 11 (1995) 1169–1173.

M. Okayasu, Y. Miyamoto and K. Morinaka, Material properties of various cast aluminum alloys made using a heated mold continuous casting technique with and without ultrasonic vibration, Metals, 5 (2015) 1440–1453.

M. Okayasu, K. Ota, S. Takeuchi, H. Ohfuji and T. Shiraishi, Influence of microstructural characteristics on mechanical properties of ADC12 aluminum alloy, Mater. Sci. Eng. A, 592 (2014) 189–200.

A. Ohno, Solidification, 1st ed., Springer, Germany (1987) 113–118.

S. Farahany, A. Ourdjini, M. H. Idrsi and S. G. Shabestari, Evaluation of the effect of Bi, Sb, Sr and cooling condition on eutectic phases in an Al-Si-Cu alloy (ADC12) by in situ thermal analysis, Thermochimica Acta., 559 (2013) 59–68.

W. Eidhed, Effects of solution treatment time and Srmodification on microstructure and mechanical property of Al-Si piston alloy, J. Mater. Sci. Technol., 24 (2008) 29–32.

S. Khan, A. Ourdjini, Q. S. Hamed, M. A. A. Najafabadi and R. Elliott, Hardness and mechanical property relationships in directionally solidified aluminum-silicon eutectic alloys with different silicon morphologies, J. Mater. Sci., 28 (1993) 5957–5962.

Author information

Authors and Affiliations

Corresponding author

Additional information

Mitsuhiro Okayasu received his Ph.D. degree from the University of Toronto in 2006. He is currently a Professor at the Department of Mechanical Engineering at Okayama University in Japan. His research interests are in the area of fatigue and fracture mechanics of the engineering materials. He is also interesting in the development of metal casting technologies and high performance piezoelectric ceramics. He has research and engineering experience of more than 10 years in automotive industries.

Rights and permissions

About this article

Cite this article

Okayasu, M., Takeuchi, S., Wu, S. et al. Effects of Sb, Sr, and Bi on the material properties of cast Al-Si-Cu alloys produced through heated mold continuous casting. J Mech Sci Technol 30, 1139–1147 (2016). https://doi.org/10.1007/s12206-016-0218-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0218-2