Abstract

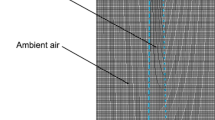

A peening method utilizing the dielectric breakdown in a liquid is presented as an alternative to current shot peening, laser shock peening and waterjet peening. These techniques are inefficient or even inapplicable for a deep notch which is typically the origin of a fatigue crack. Simulations of dielectric breakdown peening of Ti-6Al-4V alloy in oil triggered by a drop of water show that the breakdown energy is effectively delivered to the deep root of a notch, and it builds up a healthier, residual compressive zone. The major mechanism responsible for the peening is found to be the high speed, compressible impact of the oil, with a weak contribution from the shock wave propagated through the oil.

Similar content being viewed by others

References

A. Drechsler, T. Dörr and L. Wagner, Mechanical surface treatments on Ti-10V-2Fe-3Al for improved fatigue resistance, Mater. Sci. Eng., A, 243 (1998) 217–220.

S. J. Yoon, J. H. Park and N. S. Choi, Fatigue life analysis of shot-peened bearing steel, J. Mech. Sci. Tech., 26 (2012) 1747–1752.

B. P. Fairand, B. A. Wilcox, W. J. Gallagher and D. N. Williams, Laser shock-induced microstructural and mechanical property changes in 7075 aluminum, J. Appl. Phys., 43 (1972) 3893–3895.

P. Peyre, R. Fabbro, L. Berthe and C. Dubouchet, Laser shock processing of materials, physical processes involved and examples of applications, J. Laser Appl., 8 (1996) 135–141.

J. H. Kim, Y. J. Kim, J. W. Lee and S. H. Yoo, Study on effect of time parameters of laser shock peening on residual stresses using FE simulation, J. Mech. Sci. Tech., 28 (2014) 1803–1810.

R. D. Tenaglia and D. F. Lahrman, Preventing fatigue failures with laser peening, The AMPTIA Quarterly, 7 (2003) 3–7.

M. Ramulu, S. Kunaporn, M. Jenkins and M. Hashish, Peening with high pressure waterjets, SAE Tech. Paper 1999-01-2285 (1999).

D. Arola, M. L. McCain, S. Kunaporn and M. Ramulu, Waterjet and abrasive waterjet surface treatment of titanium: a comparison of surface texture and residual stress, Wear, 249 (2002) 943–950.

G. Supeene, C. R. Koch and S. Bhattacharjee, Deformation of a droplet in an electric field: Nonlinear transient response in perfect and leaky dielectric media, J. Colloid Interface Sci., 318 (2008) 463–476.

A. Vogel et al., Energy balance of optical breakdown in water at nanosecond to femtosecond time scales, Appl. Phys. B, 68 (1999) 271–280.

F. J. Heymann, High-speed impact between a liquid drop and a solid surface, J. Appl. Phys., 40 (1969) 5113–5122.

M. B. Lesser and J. E. Field, The impact of compressible liquids, Annu. Rev. Fluid Mech., 15 (1983) 97–122.

K. K. Haller, Y. Ventokos, D. Poulokakos and P. Monkewitz, Computational study of high-speed liquid drop impact, J. Appl. Phys., 92 (2002) 2821–2828.

M. Zahn, Y. Ohki, D. B. Fenneman, R. J. Gripshover and V. H. Gehman, Dielectric properties of water and water/ ethylene glycol mixtures for use in pulsed power system design, Proc. IEEE 74 (1986) 1182–1221.

D. Tommasini, Dielectric insulation and high-voltage issues, CERN-2010-004 (2010) 335–355.

Autodyn User Manual, Version 6.0

D. R. Leseur, Experimental investigation of material models for Ti-6Al-4V and 2024-T3, FAA Report DOT/FAA/AR-00/25 (2000).

http://www.spring-tech.eu/Reports/Report%2018.pdf.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jin Weon Kim

Ji Ryong Cho received his Ph.D. from the Dept. Mech. Eng., KAIST, Korea, in 1991. After research associate position at UMIST, U.K., he joined the Dept. Mech. Auto. Eng., Inje Univ., Korea. His research interests include turbulence model, incompressible flow algorithm, and fluid-shock assisted solid surface modification technique.

Rights and permissions

About this article

Cite this article

Cho, J.R. Simulation of the electric shock peening of Ti-6Al-4V alloy in oil. J Mech Sci Technol 28, 4503–4507 (2014). https://doi.org/10.1007/s12206-014-1017-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-1017-2