Abstract

Integrated waveguides with slot structures have attracted increasing attention due to their advantages of tight mode confinement and strong light-matter interaction. Although extensively studied, the issue of mode mismatch with other strip waveguide-based optical devices is a huge challenge that prevents integrated waveguides from being widely utilized in large-scale photonic-based circuits. In this paper, we demonstrate an ultra-compact low-loss slot-strip converter with polarization insensitivity based on the multimode interference (MMI) effect. Sleek sinusoidal profiles are adopted to allow for smooth connection between the slot and strip waveguide, resulting reflection reduction. By manipulating the MMI effect with structure optimization, the self-imaging positions of the TE0 and TM0 modes are aligned with minimized footprint, leading to low-loss transmission for both polarizations. The measurement results show that high coupling efficiencies of − 0.40 and − 0.64 dB are achieved for TE0 and TM0 polarizations, respectively. The device has dimensions as small as 1.1 μm × 1.2 μm and composed of factory-available structures. The above characteristics of our proposed compact slot-strip converter makes it a promising device for future deployment in multi-functional integrated photonics systems.

Graphic Abstract

Similar content being viewed by others

1 Introduction

Silicon photonics is emerging as an extensively universal platform due to their integration of various low cost, high-density photonic devices and the maturity of complementary metal-oxide semiconductor (CMOS) manufacturing technology [1,2,3,4]. Silicon-based slot waveguides are constructed with a narrow low-index slot (SiO2 or air) embedded between two high-index silicon waveguides. Owing to their unique optical field distributions [5,6,7], slot waveguides are irreplaceable in many applications, such as optical sensors [6], high speed modulators [8, 9], polarization controlling devices [10,11,12], and nonlinear optical devices [13]. However, the propagation loss of slot waveguides, which is almost one order of magnitude larger than that of strip waveguides [14, 15], poses serious challenges for realizing low loss photonic circuits based solely on slot waveguides. Thus, a compact slot-strip converter is necessary to effectively connect the slot waveguide-based functional device with other photonic components. To date, various schemes have been proposed to achieve high coupling efficiency for slot-strip converters. The adiabatic evolution structure [16,17,18] is widely used while the sharp tips cannot be avoided during gradual mode conversion, which pose great challenges for high-precision fabrication. For example, multimode interference (MMI) schemes [19, 20] produce reflections due to mutation of the waveguide. Moreover, overly narrow slots (which also existed in Ref. [21]) and non-standard silicon thicknesses also make large-scale production extremely difficult, not to mention the advanced fabrication process. Furthermore, the compactness of most schemes is insufficient. Despite its numerous challenges, polarization multiplexing technology is still an effective approach to enhance the capacity of on-chip optical interconnects [22], making polarization-insensitive mode converters [20] paramount for applications that involve multiple modes [12, 23].

In this paper, a polarization-insensitive slot-strip converter is proposed and demonstrated based on novel sinusoidal-profile MMI, which not only decreases the optical mode field mismatching but also has an ultra-compact device size. The insertion losses for TE0 and TM0 polarizations are measured as low as 0.40 and 0.64 dB, respectively. The polarization-dependent loss is 0.24 dB, indicating that the converter can handle a variety of applications where both TE0 and TM0 polarizations are needed. Theories and preliminary simulation results have been roughly investigated in Ref. [24], while this paper will present more detailed principles, simulation, and experimental results.

2 Design and principles

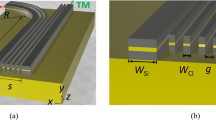

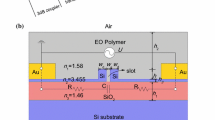

As illustrated in Figs. 1(a) and (b), the proposed converter is based on a silicon-on-insulator (SOI) platform, with a 220 nm top Si and 2 μm SiO2 cladding. The width (Wi) of the slot waveguide is set at 300 nm for specific needs and the gap (g) is fixed at 200 nm, which is compatible with standard 180 nm CMOS processes. The output strip waveguide width (Wo) is 400 nm for single mode operation. The core region, where the MMI effect and optical mode evolution take place from slot mode to strip mode, is shown in Fig. 1(d). In the calculation, {Etv, Htv} represent the transverse optical fields of the slot waveguide, while that of the eigenmodes in the MMI region is denoted as {Etm, Htm}. Based on the coupled mode theory, the mode overlap ratio (Γ) between the two structures can be described as

According to Eq. (1), the TE0 of slot mode can be expanded into TE0 and TE2 of strip mode in the MMI region and the self-imaging points would be periodically restructured. For the 800 nm width strip waveguide, the proportion of TE0 and TE2 is 89.7% and 7.6%, respectively, when the slot mode is injected. The MMI process differs from the previous MMI principle in that the proposed structure is spatially modulated by the profile. Thus, the propagation constant of each mode is variable and the position and proportion of different onefold image modes are different with each change of profile. Therefore, by appropriately designing the shape of the sinusoidal-MMI region, the desired mode distribution can be obtained at the output port.

The core region is composed of two different sinusoids with longitudinal lengths of L1 and L2. The junction of these two arcs determines the maximum width (Wt). The function of the profile is

and

The first order derivative of the sinusoidal arcs is zero at points –π/2 and π/2, which forms a smooth mode transition at the butt-joint area between the slot waveguide and MMI region for reflection reduction. To demonstrate this theory, a conventional structure in which a slot waveguide directly couples to a regular rectangle waveguide (1.2 μm width) as the MMI region was simulated. In comparison, the proposed structure can theoretically achieve a 30% reflection reduction. Other core region profiles in reality demonstrate geometric similarities when the first order derivative is zero. The differences between these structures may not be as apparent following production. Since high performance have been obtained with a sinusoidal function, this simple and easily available profile function was adopted. While previous structures require a tapered structure after the MMI/directly coupling region for single mode operation, our proposed structure does not require the additional tapered region to function, allowing for further size reduction. This is because our design combines the functions of both regions, so that the optical field can be manipulated inside the sinusoidal-MMI and the mode profile of the MMI onefold image highly overlaps with that in the 400 nm single-mode waveguide.

The ideal way to achieve polarization-insensitive mode conversion is to calculate the self-imaging positions of TE0 and TM0, where polarization constructs the onefold images. However, this may result in a larger device size since the coincident point may be located further from the starting position. In our design, the first onefold image for both TE0 and TM0 is the optimal solution because the relatively small distance between the two points can still guarantee low-loss transmission of both polarizations. Optimization of the core region structure was achieved through parameter traversing of {Wt, L1, L2} around the first onefold image as shown in Figs. 2(a) and (b), where the figure of merit (FOM) is defined as

where \(T_{{{\text{TE}}}}\) (\(T_{{{\text{TM}}}}\)) represent the normalized transmission of TE0 (TM0). A high FOM indicates high transmission for both TE0 and TM0 polarizations. Finally, dimensions of Wt = 1.1 μm, L1 = 0.4 μm, and L2 = 0.8 μm were selected for low-loss polarization-insensitive slot-strip conversion. All 3D simulations presented in this paper were carried out using finite element method (FEM). Figure 2(c) and (d) show the fabrication tolerance analysis. The waveguide width variation, ΔW (including the variation of Wi, Wt, and Wo), and the slot gap variation, Δg, are significant parameters when determining the fabrication tolerance. The simulation results indicate that the conversion efficiency decline are less than 0.3% for TE0 mode, 0.7% for TM0 mode with the variation of g within ± 20 nm, and 2.1% for TE0, 1.4% for TM0 with the variation of W within ± 20 nm.

3 Fabrication and experimental measurements

The proposed converter was fabricated in the United Microelectronics Center (CUMEC), based on standard 180 nm SiP process (Fig. 3(a)). Figure 3(b) exhibits the scanning electron microscope (SEM) image of the converter. The total length of the proposed converter is 1.2 μm. A polarization-sensitive grating coupler was used to guide the light into the chip, while maintaining high polarization selectivity for either TE0 or TM0 modes. To characterize device performance, a tunable continuous wave (CW) laser (AQ 2200-136TLS, YOKOGAWA) was used as the source and the polarization was adjusted using a polarization controller (DPC5500, THORLABS). Then, the light was coupled into the chip through the polarization-sensitive grating coupler. An optical spectrum analyzer (AQ 6370C, YOKOGAWA) was used to measure the output spectrum coupled from the output grating coupler. Figure 3(c) shows the measured transmission for both TE0 and TM0 modes, which are extracted by normalizing the measured spectra with a 400 nm width waveguide to exclude the loss of grating coupling.

a Schematic of the device measurement. PC, polarization control; TM-GC, TM polarization sensitive grating coupler; TE-GC, TE polarization sensitive grating coupler; OSA, optical spectrum analyzer. b Top-view SEM picture of fabricated converters. c Measured transmission of TE0 mode (red line) and TM0 mode (blue line); the black line are trend lines by robust locally weight regression method. The green line represents the polarization dependent loss (PDL)

The normalized spectra still show a small amount of reflection from the butt-joint since the ripple of the spectrum especially for TE0, is observed as a result of Fabry–Perot resonance. The robust locally weighted regression method has been implemented [25] to suppress the noise (shown as solid black lines in Fig. 3(c)). The insertion loss (IL), defined as \({\text{IL}}_{{{\text{TE}}_{0} ,{\text{TM}}_{0} }} = 10\log_{10} \left( {P_{{{\text{TE}}_{0} ,{\text{TM}}_{0} }} /P_{{{\text{in}}}} } \right)\), is used to characterize the transmission loss. At approximately the 1550 nm wavelength, the IL is − 0.40 and − 0.64 dB (single-ended loss) for TE0 and TM0, respectively, indicating that the proposed converter is capable of low loss transmission for both polarizations. The polarization-dependent loss (PDL), defined as \({\text{PDL}} = \left| {{\text{IL}}_{{{\text{TE}}}} - {\text{IL}}_{{{\text{TM}}}} } \right|\), is used to characterize the polarization insensitivity of the converter. The PDL of the converter is about 0.24 dB, meaning it can support most polarization-insensitive applications. Compared to other studies, the converter proposed in this paper is the most compact in size, though the IL may be slightly lower than others in Refs. [19, 20]. However, according to the coupled mode theory, a wider slot can exacerbate mode mismatch, as illustrated in Ref. [21]. With that said, we still need to overcome many challenges in order to eliminate mode mismatch for a 200 nm slot, the widest of all previous works.

4 Conclusion

In conclusion, this paper numerically and experimentally demonstrates an ultra-compact polarization-insensitive slot-strip converter that takes advantage of low-loss transmission of the MMI effect. Due to the characteristic shape of the sinusoidal arcs, the converter can create a smooth connection between the slot and single-mode strip waveguide, with only slight reflections. The proposed device is easily manufactured, with a compact dimensions of 1.1 μm × 1.2 μm. The IL for both TE0 and TM0 polarizations is lower than 0.65 dB and the PDL is about 0.24 dB at around 1550 nm. These characteristics are advantageous for various applications that require both TE0 and TM0 polarizations, such as optical sensing, high speed modulation, and polarization controlling devices.

Change history

10 August 2022

A Correction to this paper has been published: https://doi.org/10.1007/s12200-022-00031-6

References

Soref, R.: The past, present, and future of silicon photonics. IEEE J. Sel. Top. Quantum Electron. 12(6), 1678–1687 (2006)

Jalali, B., Fathpour, S.: Silicon photonics. J. Lightwave Technol. 24(12), 4600–4615 (2006)

Bai, B., Shu, H., Wang, X., Zou, W.: Towards silicon photonic neural networks for artificial intelligence. Sci. China Inf. Sci. 63(6), 160403 (2020)

Shen, B., Shu, H., Zhou, L., Wang, X.: A design method for high fabrication tolerance integrated optical mode multiplexer. Sci. China Inf. Sci. 63(6), 160409 (2020)

Almeida, V.R., Xu, Q., Barrios, C.A., Lipson, M.: Guiding and confining light in void nanostructure. Opt. Lett. 29(11), 1209–1211 (2004)

Dell’Olio, F., Passaro, V.M.N.: Optical sensing by optimized silicon slot waveguides. Opt. Express 15(8), 4977–4993 (2007)

Yamada, H., Chu, T., Ishida, S., Arakawa, Y.: Si photonic wire waveguide devices. IEEE J. Sel. Top. Quantum Electron. 12(6), 1371–1379 (2006)

Ding, R., Baehr-Jones, T., Liu, Y., Bojko, R., Witzens, J., Huang, S., Luo, J., Benight, S., Sullivan, P., Fedeli, J.M., Fournier, M., Dalton, L., Jen, A., Hochberg, M.: Demonstration of a low VπL modulator with GHz bandwidth based on electro-optic polymer-clad silicon slot waveguides. Opt. Express 18(15), 15618–15623 (2010)

Phatak, A., Cheng, Z., Qin, C., Goda, K.: Design of electro-optic modulators based on graphene-on-silicon slot waveguides. Opt. Lett. 41(11), 2501–2504 (2016)

Zheng, Z., Iqbal, M., Liu, J.: Dispersion characteristics of SOI-based slot optical waveguides. Optics Commun. 281(20), 5151–5155 (2008)

Shu, H., Deng, Q., Jin, M., Tao, Y., Wang, X., Zhou, Z. Efficient graphene phase modulator based on a polarization multiplexing optical circuit. In: Proceedings of Optical Fiber Communication Conference. Optical Society of America, W2A.9 (2019)

Deng. Q., Liu, L., Zhou, Z. Experimental demonstration of an ultra-compact on-chip polarization controlling structure. arXiv preprint arXiv:1705.10275 (2017)

Shu, H., Deng, Q., Wang, X., Jin, M., Tao, Y., Zhou, Z.: A polarization multiplexing optical circuit for efficient phase tuning. IEEE Photonics Technol. Lett. 31(19), 1549–1552 (2019)

Hochberg, M., Baehr-Jones, T., Wang, G., Huang, J., Sullivan, P., Dalton, L., Scherer, A.: Towards a millivolt optical modulator with nano-slot waveguides. Opt. Express 15(13), 8401–8410 (2007)

Thylén, L., Wosinski, L.: Integrated photonics in the 21st century. Photonics Res. 2(2), 75–81 (2014)

Zhang, H., Zhang, J., Chen, S., Song, J., Kee, J.S., Yu, M., Lo, G.Q.: CMOS-compatible fabrication of silicon-based sub-100-nm slot waveguide with efficient channel-slot coupler. IEEE Photonics Technol. Lett. 24(1), 10–12 (2012)

Wang, Z., Zhu, N., Tang, Y., Wosinski, L., Dai, D., He, S.: Ultracompact low-loss coupler between strip and slot waveguides. Opt. Lett. 34(10), 1498–1500 (2009)

Feng, N.N., Sun, R., Kimerling, L.C., Michel, J.: Lossless strip-to-slot waveguide transformer. Opt. Lett. 32(10), 1250–1252 (2007)

Deng, Q., Liu, L., Li, X., Zhou, Z.: Strip-slot waveguide mode converter based on symmetric multimode interference. Opt. Lett. 39(19), 5665–5668 (2014)

Deng, Q., Yan, Q., Liu, L., Li, X., Michel, J., Zhou, Z.: Robust polarization-insensitive strip-slot waveguide mode converter based on symmetric multimode interference. Opt. Express 24(7), 7347–7355 (2016)

Han, K., Kim, S., Wirth, J., Teng, M., Xuan, Y., Niu, B., Qi, M.: Strip-slot direct mode coupler. Opt. Express 24(6), 6532–6541 (2016)

Zhou, Z., Bai, B., Liu, L.: Silicon on-chip PDM and WDM technologies via plasmonics and subwavelength grating. IEEE J. Sel. Top. Quantum Electron. 25(3), 1–13 (2018)

Chen, R., Bai, B., Zhou, Z.: Low-loss hybrid plasmonic TM-pass polarizer using polarization-dependent mode conversion. Photonics Res. 8(7), 1197–1202 (2020)

Tao, Z., Bai, B., Chen, R., Wang, X.: Adiabatic slot-to-strip waveguide mode converters based on self-imaging effect of MMI structures. In: Proceedings of Asia Communications and Photonics Conference. Optical Society of America, M4A.146 (2020)

Cleveland, W.S.: Robust locally weighted regression and smoothing scatterplots. J. Am. Stat. Assoc. 74(368), 829–836 (1979)

Acknowledgements

This work was funded by the National Key Research and Development Program of China (No. 2018YFB2201704), the National Natural Science Foundation of China (Grant Nos. 61635001 and 62105008), China National Postdoctoral Program for Innovative Talents (No. BX20200017), China Postdoctoral Science Foundation (No. 2021T140004), the Major Key Project of PCL (No. PCL2021A14). We would like to thank Yuansheng Tao, Ming Jing, and Bitao Shen for their fruitful discussions, and Ziyi Wei for taking the SEM images.

Author information

Authors and Affiliations

Contributions

The authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

The original version of this article was revised: the Fig. 3 was updated.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tao, Z., Wang, B., Bai, B. et al. An ultra-compact polarization-insensitive slot-strip mode converter. Front. Optoelectron. 15, 5 (2022). https://doi.org/10.1007/s12200-022-00008-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12200-022-00008-5