Abstract

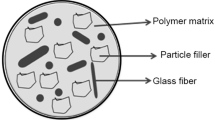

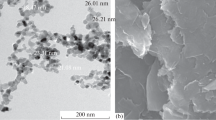

An E-glass-reinforced epoxy-based nanocomposite containing organomodified nanoclay (15–20 nm) and calcium silicate particles (75–149 μm) was developed through mechanical shearing mixing and hand layup techniques. Three weight fractions (2, 3 and 4%) of nanoclay were selected to study the effects of nanoclay on mechanical and wear behaviour of nanocomposites. Tensile and flexural properties of nanocomposites were evaluated and compared. The wear properties were evaluated for three speed (3.14, 4.19 and 5.24 m s−1) and load (20, 50, and 80 N) conditions based on a design of experiment (L16 matrix) concept. The wear loss results were statistically analysed to study the significance of load, speed and nanoclay content. The morphologies of wear surface and fracture surface were examined with the aid of a scanning electron microscope (SEM) to identify the wear and fracture mechanisms. It was found that the wear loss increases with increasing nanoclay amount due to the particle agglomeration effects. Statistical analysis determines that the load is the most significant parameter affecting the wear resistance of nanocomposites. The mean and S/N ratio analyses rank the parameters significance in affecting wear resistance as follows: load > nanoclay content > speed. The wear mechanisms of nanocomposites are complex due to the observation of multiple features such as fibre thinning, matrix wear and fibre/matrix debonding as against abrasive wear in the pure epoxy. Tensile and flexural test results show that a good dispersion of nanoclay is achieved with 2 wt% amount in epoxy-based nanocomposites. The mechanical properties degrade above 2 wt% due to the excessive reinforcement, uneven distribution and the particle agglomeration effects. Fractography studies of tension-failed samples show that pure epoxy resin fails by multimode gauge explosive mode, whereas nanocomposites fail mainly by the matrix/fibre interface failure and fibre breakages.

Similar content being viewed by others

References

Sampathkumaran P, Seetharamu S, Murali A, Kumar R K and Kishore 1998 Bull. Mater. Sci. 21 335

Naeimirad M, Zadhoush A and Neisiany R E 2016 J. Compos. Mater. 50 435

Prabhu T R, Varma V K and Vedantam S 2014 Wear 309 247

Hussain F, Hojjati M, Okamoto M and Gorga R E 2006 J. Compos. Mater. 40 1511

Barbezat M, Brunner A J, Necola A, Rees M, Gasser Ph and Terrasi G 2009 J. Compos. Mater. 43 9

Zhang Z, Breidt C, Chang L, Haupert F and Friedrich K 2004 Composites Part A 35 1385

Singh R P, Zhang M and Chan D 2002 J. Mater. Sci. 37 781

Wang K, Chen L, Wu J, Toh M L, He C and Yee A F 2005 Macromolecules 38 788

Jordan J, Jacob K I, Tannenbaum R, Sharaf M A and Jasiuk I 2005 Mater. Sci. Eng. A 393 1

Bashar M, Mertiny P and Sundararaj U 2014 J. Nanomater. 1 (http://dx.doi.org/10.1155/2014/312813)

Utracki L A 2004 Clay-containg polymeric nanocomposites vol 2 (Shrewsbury, Shropshire, UK: Rapra Technology Limited)

Giannelis E P 1996 Adv. Mater. 8 29

Laine R M, Choi J and Lee I 2001 Adv. Mater. 13 800

Wetzel B, Haupert F, Friedrich K, Zhang M Q and Rong M Z 2002 Polym. Eng. Sci. 42 1919

Wetzel B, Haupert F and Zhang M Q 2003 Compos. Sci. Technol. 63 2055

Chang L and Zhang Z 2006 Wear 260 869

Zhang Z and Friedrich K 2005 In: K Friedrich, S Fakirovc and Z Zhang (eds) Polymer composites—from nano- to macro-scale (New York, NY 10013, USA: Springer) p 169

Zhang M Q, Rong M Z, Yu S L, Wetzel B and Friedrich K 2002 Wear 253 1086

Durand J M, Vardavoulias M and Jeandin M 1995 Wear 181 833

Chee C Y, Song N L, Abdullah L C, Choong T S Y, Ibrahim A and Chantara T R 2012 J. Nanomater. 2012 1

Zhang M Q, Rong M Z, Yu M L, Wetzel B and Friedrich K 2002 Macromol. Mater. Eng. 287 111

Ng C B, Schadler L S and Siegel R W 1999 Nanostruct. Mater. 12 507

Rong M Z, Zhang M Q, Liu H, Zeng H M, Wetzel B and Friedrich K 2001 Ind. Lubr. Tribol. 53 72

Shi G, Zhang M Q, Rong M Z, Wetzel B and Friedrich K 2004 Wear 256 1072

Petrovic Z S, Javni I, Waddon A and Banhegyi G 2000 J. Appl. Polym. Sci. 76 133

Prabhu T R 2015 Mater. Des. 77 149

Reynaud E, Jouen T, Gautheir C, Vigier G and Varlet J 2001 Polymer 42 8759

Haque A, Shamsuzzoha M, Hussain F and Dean D 2003 , J. Compos. Mater. 37 1821

Luo J J and Daniel I M 2003 Compos. Sci. Technol. 63 1607

Lan T and Pinnavaia T J 1994 Chem. Mater. 6 2216

Pinnavaia T J, Lan T, Wang Z, Shi H and Kaviratna P D 2009 ACS Symp. Ser. 622 250

Chan C M, Wu J, Li J X and Cheung Y K 2002 Polymer 43 2981

Rong M Z, Zhang M Q, Zheng Y X, Zeng H M, Walter R and Friedrich K 2001 Polymer 42 167

Nielsen L E and Landel R F 1993 Mechanical properties of polymers and composites, 2nd edn (New York: CRC Press, Taylor & Francis Group)

Roulin-Moloney A C 1989 Fractography and failure mechanisms of polymers and composites (Barking, England: Elsevier Applied Science)

Prabhu T R 2015 Bull. Mater. Sci. 38 753

Prabhu T R, Varma V K and Vedantam S 2014 Wear 317 201

Prabhu T R and Vedantam S 2015 Tribol. Trans. 58 718

Prabhu T R, Varma V K and Vedantam S 2014 J. Mater. Eng. Perform. 23 3666

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

PRABHU, T.R., BASAVARAJAPPA, S., SANTHOSH, R.B. et al. Tribological and mechanical behaviour of dual-particle (nanoclay and CaSiO3)-reinforced E-glass-reinforced epoxy nanocomposites. Bull Mater Sci 40, 107–116 (2017). https://doi.org/10.1007/s12034-016-1355-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-016-1355-z