Abstract

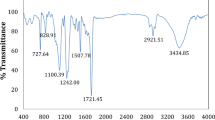

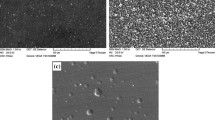

Ni–Mo+PTh composite coatings were prepared from nickel–molybdenum galvanic bath with the addition of thiophene (Th) and HClO4 as result of two processes: induced Ni–Mo alloy deposition and PTh polymerization. A scanning electron microscope was used for surface morphology characterization of the coatings. The Scanning Electrochemical Workstation M370 was used to the surface map of the tested composite coatings. The chemical composition of the coatings was determined by the energy-dispersive spectroscopy (EDS) method. It was stated that the surface of the coatings are characterized by the presence of Ni–Mo particles and polythiophene agglomerates. Electrochemical corrosion investigations of coatings were carried out in the 5 M KOH solution, using voltammetry and electrochemical impedance spectroscopy (EIS) methods. On the basis of these research works it was found that the composite Ni–Mo+PTh coatings are more corrosion resistant in alkaline solution than Ni–Mo. The reasons for this are the presence of the polymer on the surface of the coatings and a decrease of corrosion active surface area of the coatings.

Similar content being viewed by others

References

Hamid Z A and Ghayad J M 2002 Mater. Lett. 53 238

Karolus M, Niedbała J, Rówiński E, Lagiewka E and Budniok A 2006 J. Achiev. Mater. Manufact. Eng. 16 25

Niedbała J, Budniok A and Lkagiewka E 2006 Mater. Sci. Forum 514–516 1176

Niedbała J, Budniok A and Lkagiewka E 2007 InŻ. Mater. (Mater. Eng.) 155 21

Niedbała J, Budniok A and Lagiewka E 2008 Thin Solid Films 516 6191

Niedbała J 2008 Using carbon nanomaterials in clean-energy hydrogen systems, Series: NATO science for peace and security series, Subseries: NATO Science for Peace and Security Series C: Environmental Security, XXXIV, Hardcover, Springer ISBN: 978-1-4020-8896-4

Niedbała J 2009 Mater. Chem. Phys. 118 46

Niedbała J 2011 Bull. Mater. Sci. 34 993

Rówiński E, Karolus M and Lkagiewka E 2007 Solid State Phenom. 130 245

Lindfors T, Bobacka J, Lewen Stam A and Ivaska A 1998 Electrochim. Acta 43 3503

Karolus M, Rówiński E and Lagiewka E 2006 J. Achiev. Mater. Manuf. Eng. 18 119

Fenelon A M and Breslin C B 2002 Electrochim. Acta 47 4467

Kuwabata S, Masui S, Tomiyori H and Yoneyama H 2000 Electrochim. Acta 46 91

Levi M D, Gofer Y and Aurbach D 2002 Polym. Adv. Technol. 13 697

Rajagopalan R and Iroh J O 2002 Surf. Eng. 18 59

Birry L and Lasia A 2004 J. Appl. Electrochem. 34 735

Jakšic J M, Vojnovic M V and Krstajic N V 2000 Electrochim. Acta 45 4151

Niedbała J, Popczyk M, Budniok A and Lagiewka E 2004 KSCS 2004 mechanisms of corrosion and corrosion prevention (Helsinki University of Technology) p 195

Niedbała J 2006, Mater. Sci. Forum 514–516 465

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

NIEDBAŁA, J. Structure, morphology and corrosion resistance of Ni–Mo+PTh composite coatings. Bull Mater Sci 38, 695–699 (2015). https://doi.org/10.1007/s12034-015-0922-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0922-z