Abstract

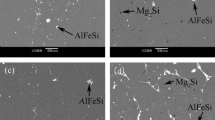

This paper presents test results concerning the selection of sodium salt for the technology of continuous modification of the EN AC-AlSi12 alloy, which is based on electrolysis of sodium salts, occurring directly in a crucible with liquid alloy. Sodium ions formed as a result of the sodium salt dissociation and the electrolysis are ‘transferred’ through walls of the retort made of solid electrolyte. Upon contact with the liquid alloy, which functions as a cathode, sodium ions are transformed into the atomic state, modifying the alloy. As a measure of the alloy modification extent, the obtained increase of the tensile strength R m and change of metallographic structure are used, confirming obtained modification effect of the investigated alloy.

Similar content being viewed by others

References

Pacz A 1921 US Patent No. 1387900

Pietrowski S 2001 Silumins (Łódź: Technical University Editorial) p 195

Fatahalla N, Hafız M and Abdulkhalek M 1999 J. Mater. Sci. 34 3555

Nogita K and Dahle A K 2001 Mater. Trans. 42 207

Hegde S and Prabhu K N 2008 J. Mater. Sci. 43 3009

Closset B and Gruzleski J E 1982 Metall. Trans. A 13 945

Gilbert J and Rooy E L 2004 Aluminum alloy castings: properties, processes and applications (OH, USA: ASM International) p 40

Nogita K, McDonald S D and Dahle A K 2004 Mater. Trans. 45 323

Krupiński M, Labisz K, Dobrzański L A and Rdzawski Z 2010 Arch. Foundry Eng. 10 79

Davis J R 1993 Aluminum and aluminum alloys (OH, USA: ASM International) p 223

Poniewierski Z 1989 Crystallization and properties of silumins (Warszawa: WNT) p 73

Wasilewski P 1993 Modification and its impact on structure and properties. Monography, solidification of metals and alloys (PAN Katowice) Vol. 21, p 106

Białobrzeski A, Dudek P, Fajkiel A, Leśniewski W et al 2006 Arch. Foundry 6 97

Białobrzeski A, Saja K and Leśniewski W 2007 Arch. Foundry Eng. 7 57

Yan X Y, Langberg D E and Rankin W J 1995 Metall. Mater. Trans. B 26 1005

Dunn B and Farrington G C 1980 Mater. Res. Bull. 15 1773

Wen Z, Cao J, Gu Z, Xu X, Zhang F and Lin Z 2008 J. Solid State Ionics 179 1697

Moseley P T, Bones R J, Teagle D A, Bellamy B A and Hawes R W M 1989 J. Electrochem. Soc. 136 1361

Lu X C, Xia G G, Lemmon J P and Yang Z G 2010 J. Power Sources 195 2431

May G J 1978 J. Power Sources 3 1

Sudworth J L 2001 J. Power Sources 100 149

Fray D J 2003 Metall. Mater. Trans. B 34 589

Fray D J 1977 Metall. Trans. B 8 153

Doughty G, Fray D J, Van Der Poorten C and DeKeyser J 1996 J. Solid State Ionics 86–88 193

Białobrzeski A 2007 Arch. Foundry Eng. 7 53

Sigworth G K 1983 AFS Trans. 91 7

Pan E N, Cherng Y G, Lin C A and Chiou H S 1994 AFS Trans. 70 609

Fredriksson H, Hillert M and Lange N 1973 J. Inst. Met. 101 285

Liu Q Y, Li Q C and Liu Q F 1991 Acta Metall. Mater. 39 2497

Rathoda H R and Manghani J V 2012 Int. J. Emerg. Trends Eng. Dev. 2 573

Brown J 1999 Foseco non-ferrous Foundryman’s handbook (UK: Butterworth-Heinemann) p 56

Mondolfo L F 1965 J. Austral. Inst. Met. 10 169

Lu S Z and Hellawell A 1987 Metall. Mater. Trans. A 18 1721

Onyia C, Okorie B, Neife S and Obayi C 2013 World J. Eng. Technol. 1 9

Jian X, Meek T and Han Q 2006 Scr. Mater. 54 893

Nafisi S and Ghomashchi R 2006 Mater. Sci. Eng. A 415 273

Liu L, Samuel A M, Samuel F H, Doty H W and Valtierra S 2004 J. Mater. Sci. 39 215

Zhang X H, Su G C, Ju C W, Wang W C and Yan W L 2010 Mater. Des. 31 4408

Acknowledgement

The present work was performed within framework of Research Project no. 3 T08B 063 29 financed by the State Committee for Scientific Research (MNiSW).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

PEZDA, J., BIAŁOBRZESKI, A. Use of sodium salt electrolysis in the process of continuous modification of eutectic EN AC-AlSi 1 2 alloy. Bull Mater Sci 38, 373–377 (2015). https://doi.org/10.1007/s12034-015-0875-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0875-2