Abstract

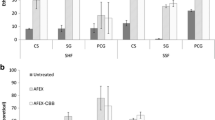

Lignocellulosic feedstocks corn stover, prairie cord grass, and switchgrass were subjected to ammonia fiber expansion (AFEX™) pretreatment and densified using extrusion pelleting and ComPAKco densification technique. The effects of AFEX™ pretreatment and densification were studied on the fast pyrolysis product yields. Feedstocks were milled in a hammer mill using three different screen sizes (2, 4, and 8 mm) and were subjected to AFEX™ pretreatment. The untreated and AFEX™-pretreated feedstocks were moisture adjusted at three levels (5, 10, and 15 % wb) and were extruded using a lab-scale single screw extruder. The barrel temperature of the extruder was maintained at 75, 100, and 125 °C. Durability of the extruded pellets made from AFEX™-pretreated corn stover, prairie cord grass, and switchgrass varied from 94.5 to 99.2, 94.3 to 98.7, and 90.1 to 97.5 %, respectively. Results of the thermogravimetric analysis showed the decrease in the decomposition temperature of the all the feedstocks after AFEX™ pretreatment indicating the increase in thermal stability. Loose and densified feedstocks were subjected to fast pyrolysis in a lab-scale reactor, and the yields (bio-oil and bio-char) were measured. Bio-char obtained from the AFEX™-pretreated feedstocks exhibited increased bulk and particle density compared to the untreated feedstocks. The properties of the bio-oil were statistically similar for the untreated, AFEX™-pretreated, and AFEX™-pretreated densified feedstocks. Based on the bio-char and bio-oil yields, the AFEX™-pretreated feedstocks and the densified AFEX™-pretreated feedstocks (pellets and PAKs) exhibited similar behavior. Hence, it can be concluded that densifying the AFEX™-pretreated feedstocks could be a viable option in the biomass-processing depots to reduce the transportation costs and the logistical impediments without affecting the product yields.

Similar content being viewed by others

References

Hess, J. R., Wright, C. T., Kenney, K. L. and Searcy, E. M. (2009) Uniform-format solid feedstock supply system. A commodity-scale design to produce an infrastructure-compatible bulk solid from lignocellulosic biomass—executive summary. Idaho National Laboratory Idaho Falls, Idaho 83415.

Tumuluru, J. S., Wright, C. T., Hess, J. R., & Kenney, K. L. (2011). A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuel Bioprod Bior, 5, 683–707.

Miao, Z., Grift, T. E., Hansen, A. C., & Ting, K. C. (2013). Energy requirement for lignocellulosic feedstock densifications in relation to particle physical properties, preheating, and binding agents. Energy & Fuels, 27, 588–595.

Tumuluru, J. S., Wright, C. T., Kenney, K. L. and Hess, J. R. (2010) A review on biomass densification technologies for energy application Idaho Falls, Idaho 83415.

Eranki, P. L., Bals, B. D., & Dale, B. E. (2011a). Advanced regional biomass processing depots: a key to the logistical challenges of the cellulosic biofuel industry. Biofuel Bioprod Bior, 5, 621–630.

Eranki, P. L., & Dale, B. E. (2011b). Comparative life cycle assessment of centralized and distributed biomass processing systems combined with mixed feedstock landscapes. GCB Bioenergy, 3, 427–438.

Balan, V., Bals, B., Chundawat, S. P. S., Marshall, D. and Dale, B. E. (2009), in Biofuels: methods and protocols, (Mielenz, R. J., ed.), Humana Press, Totowa, NJ, pp. 61–77.

Alvira, P., Tomás-Pejó, E., Ballesteros, M., & Negro, M. J. (2010). Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresource Technol, 101, 4851–4861.

Dale, B. E. (1986) Method for increasing the reactivity and digestibility of cellulose with ammonia. Google Patents no.4600590.

Bonner, I. J., Thompson, D. N., Teymouri, F., Campbell, T., Bals, B., & Tumuluru, J. S. (2015). Impact of sequential ammonia fiber expansion (AFEX) pretreatment and pelletization on the moisture sorption properties of corn stover. Drying Technology, 33, 1768–1778.

Bridgwater, A. V., & Peacocke, G. V. C. (2000). Fast pyrolysis processes for biomass. Renewable and Sustainable Energy Reviews, 4, 1–73.

Bridgwater, A. V. (2012). Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenerg, 38, 68–94.

Theerarattananoon, K., Xu, F., Wilson, J., Staggenborg, S., Mckinney, L., Vadlani, P., Pei, Z., & Wang, D. (2012). Impact of pelleting and acid pretreatment on biomass structure and thermal properties of wheat straw, corn stover, big bluestem, and sorghum stalk. T Asabe, 55, 1845–1858.

Hoover, A. N., Tumuluru, J. S., Teymouri, F., Moore, J., & Gresham, G. (2014). Effect of pelleting process variables on physical properties and sugar yields of ammonia fiber expansion pretreated corn stover. Bioresource Technol, 164, 128–135.

Rijal, B., Biersbach, G., Gibbons, W. R., & Pryor, S. W. (2014). Effect of initial particle size and densification on AFEX-pretreated biomass for ethanol production. Applied Biochemistry and Biotechnology, 174, 845–854.

Sundaram, V., & Muthukumarappan, K. (2016). Impact of AFEX™ pretreatment and extrusion pelleting on pellet physical properties and sugar recovery from corn stover, prairie cord grass, and switchgrass. Applied Biochemistry and Biotechnology, 1–18.

Amin, N. A. S., Misson, M., Haron, R., Kamaroddin, M. F. A., Omar, W. N. N. W., & Haw, K. G. (2012). Bio-oils and diesel fuel derived from alkaline treated empty fruit bunch (EFB). International journal of biomass & renewables, 1, 6–14.

Kasparbauer, R. D. (2009) The effects of biomass pretreatments on the products of fast pyrolysis. Master of Science, Iowa State University.

Karki, B., Muthukumarappan, K., Wang, Y., Dale, B., Balan, V., Gibbons, W. R., & Karunanithy, C. (2015). Physical characteristics of AFEX-pretreated and densified switchgrass, prairie cord grass, and corn stover. Biomass and Bioenergy, 78, 164–174.

Sundaram, V., Muthukumarappan, K., & Kamireddy, S. R. (2015). Effect of ammonia fiber expansion (AFEXTM) pretreatment on compression behavior of corn stover, prairie cord grass and switchgrass. Industrial Crops and Products, 74, 45–54.

Sundaram, V., & Muthukumarappan, K. (2016). Influence of AFEX™ pretreated corn stover and switchgrass blending on the compaction characteristics and sugar yields of the pellets. Industrial Crops and Products, 83, 537–544.

ASABE. (2006) ASABE Standards S358.2 Moisture measurement—forages. St. Joseph, US.

ASTM D3175-11. (2011) Standard test method for volatile matter in the analysis sample of coal and coke. ASTM International, West Conshohocken, PA.

ASTM D3174-12. (2012) Standard test method for ash in the analysis sample of coal and coke from coal., ASTM International, West Conshohocken, PA.

Evans, R. J., Knight, R. A., Onischak, M. and Babu, S. P. (1988) Development of biomass gasification to produce substitute fuels. pp. Medium: ED; Size: Pages: 189.

Kumar, A., Wang, L., Dzenis, Y. A., Jones, D. D., & Hanna, M. A. (2008). Thermogravimetric characterization of corn stover as gasification and pyrolysis feedstock. Biomass and Bioenergy, 32, 460–467.

Moutsoglou, A. (2012). A comparison of prairie cordgrass and switchgrass as a biomass for syngas production. Fuel, 95, 573–577.

Campbell, T. J., Teymouri, F., Bals, B., Glassbrook, J., Nielson, C. D., & Videto, J. (2013). A packed bed ammonia fiber expansion reactor system for pretreatment of agricultural residues at regional depots. Biofuels, 4, 23–34.

Yang, H. P., Yan, R., Chen, H. P., Lee, D. H., & Zheng, C. G. (2007). Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel, 86, 1781–1788.

Prins, M. J., Ptasinski, K. J., & Janssen, F. J. J. G. (2006). Torrefaction of wood—part 1. Weight loss kinetics. J Anal Appl Pyrol, 77, 28–34.

Randriamanantena, T., Razafindramisa, F. L., Ramanantsizehena, G., Bernes, A. and Lacabane, C. (2009) Thermal behaviour of three woods of Madagascar by thermogravimetric analysis in inert atmosphere. Proceedings of the Fourth High-Energy Physics International Conference. Antananarivo, Madagascar.

Bals, B., Murnen, H., Allen, M., & Dale, B. (2010). Ammonia fiber expansion (AFEX) treatment of eleven different forages: improvements to fiber digestibility in vitro. Anim Feed Sci Tech, 155, 147–155.

Chundawat, S. P. S., Venkatesh, B., & Dale, B. E. (2007). Effect of particle size based separation of milled corn stover on AFEX pretreatment and enzymatic digestibility. Biotechnology and Bioengineering, 96, 219–231.

Shaw, M. D., Karunakaran, C., & Tabil, L. G. (2009). Physicochemical characteristics of densified untreated and steam exploded poplar wood and wheat straw grinds. Biosystems. Engineering, 103, 198–207.

Lee, E. Y., Lim, K. I., Lim, J. K., & Lim, S. T. (2000). Effects of gelatinization and moisture content of extruded starch pellets on morphology and physical properties of microwave-expanded products. Cereal Chemistry, 77, 769–773.

Kashaninejad, M., & Tabil, L. G. (2011). Effect of microwave–chemical pre-treatment on compression characteristics of biomass grinds. Biosystems. Engineering, 108, 36–45.

Kaliyan, N., & Morey, R. V. (2009). Densification characteristics of corn stover and switchgrass. T Asabe, 52, 907–920.

Roos, Y.H. (1995). Phase transitions in foods. Academic Press, San Diego, USA, 360 p.

Grover, P. D. and Mishra, S. K. (1996) Biomass briquetting: technology and practices. Food and agriculture organization of the United Nations, Bangkok.

Kaliyan, N., & Morey, R. V. (2010). Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresource Technol, 101, 1082–1090.

Mani, S., Tabil, L. G. and Sokhansanj, S. (2004) Evaluation of compaction equations applied to four biomass species. Canadian Biosysecondstems Engineering, 46, 3.55–53.61.

MacBain, R. (1966) Pelleting animal feed. American Feed Manufacturers Association, Virginia, USA.

Harun, S., Balan, V., Takriff, M. S., Hassan, O., Jahim, J., & Dale, B. E. (2013). Performance of AFEX™ pretreated rice straw as source of fermentable sugars: the influence of particle size. Biotechnology for Biofuels, 6, 1–17.

Singh, S., Varanasi, P., Singh, P., Adams, P. D., Auer, M., & Simmons, B. A. (2013). Understanding the impact of ionic liquid pretreatment on cellulose and lignin via thermochemical analysis. Biomass and Bioenergy, 54, 276–283.

Pattiya, A. (2011). Bio-oil production via fast pyrolysis of biomass residues from cassava plants in a fluidised-bed reactor. Bioresource Technol, 102, 1959–1967.

Zhang, Q., Chang, J., Wang, T., & Xu, Y. (2007). Review of biomass pyrolysis oil properties and upgrading research. Energy Conversion and Management, 48, 87–92.

Karunanithy, C. and Muthukumarappan, K. (2011) Rheological characterization of bio-oils from pilot scale microwave assisted pyrolysis. ed.

Yu, F., Deng, S., Chen, P., Liu, Y., Wan, Y., Olson, A., Kittelson, D., & Ruan, R. (2007). Physical and chemical properties of bio-oils from microwave pyrolysis of corn stover. Applied Biochemistry and Biotechnology, 137, 957–970.

Anouti, S., Haarlemmer, G., Déniel, M., & Roubaud, A. (2016). Analysis of physicochemical properties of bio-oil from hydrothermal liquefaction of blackcurrant pomace. Energy & Fuels, 30, 398–406.

Pandey, A., Larroche, C., Ricke, S., Dussap, C.-G. and Gnansounou, E. (2011) Biofuels—alternative feedstocks and conversion processes. Elsevier.

Dobele G., Urbanovich I., Volpert A., Kampars V. and Samulis, E. (2007) Fast pyrolysis—effect of wood drying on the yield and properties of bio-oil. ed.

Chundawat, S. P., Beckham, G. T., Himmel, M. E., & Dale, B. E. (2011). Deconstruction of lignocellulosic biomass to fuels and chemicals. Annual review of chemical and. Biomolecular Engineering, 2, 121–145.

ASAE, C. (2001) Pellets and crumbles—definitions and methods for determining density, durability and moisture content. American Society of Agricultural Engineers.

Acknowledgments

The authors acknowledge the partial funding provided by Agricultural Experiment Station and the North Central Regional Sun Grant Center at South Dakota State University through a grant provided by the US Department of Transportation, Office of the Secretary, Grant No. DTOS59-07-G-00054 and through a grant provided by the US Department of Energy Bioenergy Technologies Office under award number DE-FG36-08GO88073. The authors would like to thank Dr. Lin Wei, Assistant Professor in the Department of Agricultural and Biosystems Engineering, South Dakota State University, for providing the valuable assistance in pyrolysis experiments. The authors would also like to Ms. Christina Gerometta in the Department of Mechanical Engineering, South Dakota State University, for providing assistance in thermogravimetric analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sundaram, V., Muthukumarappan, K. & Gent, S. Understanding the Impacts of AFEX™ Pretreatment and Densification on the Fast Pyrolysis of Corn Stover, Prairie Cord Grass, and Switchgrass. Appl Biochem Biotechnol 181, 1060–1079 (2017). https://doi.org/10.1007/s12010-016-2269-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2269-3