Abstract

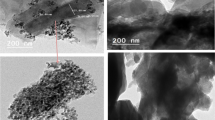

The aim of this study was to optimize the modification of Egyptian kaolinite for application in paper coating. The study focused on four modification methods; sedimentation process, chemical bleaching, calcination, and dealumination. The effect of these methods on the structure of kaolinite was studied using X-ray fluorescence (XRF), X-ray diffractometer (XRD), Fourier transform infrared spectrometer analysis, and field emission SEM. The original and modified kaolinites were applied in paper coating mixtures. The results of XRF analysis showed that the Fe2O3 and TiO2 in Egyptian kaolinite were reduced chemically via sodium dithionite from 0.41% to 0.25% and 2.20% to 2.00%, respectively. Calcination at 900°C, followed by acid activation and bleaching, showed a further decrease in Fe2O3 and TiO2 impurities to 0.012 and 1.45 (wt%), respectively. XRD results revealed that all characteristics reflection of kaolinite disappeared upon calcination. SEM investigation showed a significant reduction in kaolinite particle size. Calcination and dealumination of kaolinite did not improve coated paper roughness, while air permeance and optical properties significantly increased in comparison with commercial kaolinite. In addition, a significant improvement was observed in coated paper mechanical properties including burst, tensile strength, stretch, and tensile energy absorption with respect to original and commercial kaolinite. In contrast, the kaolinite fraction <2 µm highly improved paper gloss, print density, and print gloss, more than calcined kaolinite and its modified pigments. In conclusion, dealumination of calcined kaolinite did not show any further change in all coated paper properties compared to the calcined ones.

Similar content being viewed by others

References

Lehtinen, E, “Pigment Coating and Surface Sizing of Paper.” In: Gullichsen, J, Paulapuro, H (eds.) Paper Making Science and Technology, Vol. 11. Fapet Oy, Helsinki (2000)

Drage, G, Tamms, O, “Pigment Coating and Surface Sizing of Paper.” In: Gullichsen, J, Paulapuro, H (eds.) Paper Making Science and Technology, Vol. 11. Fapet Oy, Helsinki (2000)

Bergaya, F, Lagaly, G (eds.), Handbook of Clay Science vol. 5 for Description of Kaolinite Structure, 2nd ed. Elsevier Ltd., Amsterdam (2013)

Rissa, K, Lepistö, T, Yrjölä, K, “Effect of Kaolin Content on Structure and Functional Properties of Water-Based Coatings.” Prog. Org. Coat., 55 (2) 137–141 (2006)

Luz, AB, Middea, A, Purification of Kaolin by Selective Flocculation. Center for Mineral Technology-CETEM, Rio de Janeiro (2004)

Murray, HH, Kogel, JE, “Engineered Clay Products for the Paper Industry.” Appl. Clay Sci., 29 (3–4) 199–206 (2005)

Raghavan, P, Chandrasekhar, S, Vogt, V, Gock, E, Suresh, N, “Additional Investigations on the Separation of Titanoferrous Impurities from Kaolin by High Shear Pretreatment and Froth Flotation Part II.” Appl. Clay Sci., 42 (1) 50–56 (2008)

Sarbatly, R, Yee, CP, Fong, TS, Krishnaiah, D, “Particle Size Distribution and Purification of Red Clay for Industrial Use.” J. Appl. Sci., 9 (12) 2344–2347 (2009)

Cheng, H, Yang, J, Liu, Q, Du, X, Frost, RL, “Influencing Factors on Kaolinite—Potassium Acetate Intercalation Complexes.” Appl. Clay Sci., 50 (4) 476–480 (2010)

Morsy, FA, El-Sherbiny, S, Hassan, MS, Mohamed, HF, “Modification and Evaluation of Egyptian Kaolinite as Pigment for Paper Coating.” Powder Technol., 264 430–438 (2014)

Chandrasekhar, S, Ramaswamy, S, “Influence of Mineral Impurities on the Properties of Kaolin and Its Thermally Treated Products.” Appl. Clay Sci., 21 (3–4) 133–142 (2002)

Komadel, P, “Chemically Modified Smectites.” Clay Miner., 38 (1) 127–138 (2003)

Youssef, AA, “Upgrading of Egyptian Kaolin to Meet Specifications for Paper and Ceramic Industries.” Final Report, CMRDI, Presented to Academy of Scientific Research and Technology, Cairo, Egypt, 1994

Abdel-Khalek, N, “The Egyptian Kaolin: An Outlook in the View of the New Climate of Investment.” Appl. Clay Sci., 15 (3) 325–336 (1999)

Okada, K, Yoshizaki, H, Kameshima, Y, Nakajima, A, “Effect of the Crystallinity of Kaolinite Precursors on the Properties of Mesoporous Silicas.” Appl. Clay Sci., 41 (1) 10–16 (2008)

Hu, P, Yang, H, “Insight into the Physicochemical Aspects of Kaolins with Different Morphologies.” Appl. Clay Sci., 74 58–65 (2013)

Hassan, MS, Salem, SM, “Distribution and Influence of Iron Phases on the Physico-Chemical Properties of Phyllosilicates.” Chin. J. Geochem., 20 (2) 120–129 (2001)

Bundy, WM, Murray, HH, “The Effect of Aluminium on the Surface Properties of Kaolinite.” Clays Clay Miner., 21 (5) 295–302 (1973)

Boulis SN, Attia AKM, “Mineralogical and Chemical Composition of Carboniferous and Cretaceous Kaolinite from Number of Localities in Egypt.” Proceeding of the 1st International Symposium on Industrial Application of Clays, pp. 99–127, The Mineralogical Society of Egypt, Cairo, 1994.

Wojciech, F, Jerzy, K, Małgorzata, F, “Mineralogical Characteristics and Textural Properties of Acid-Activated Glauconite.” Mineral. Pol., 35 (2) 53–60 (2004)

Frost, RL, “Fourier Transform Raman Spectroscopy of Kaolinite, Dickite and Halloysite.” Clays Clay Miner., 43 (2) 191–195 (1995)

Frost, RL, Vassallo, AM, “The Dehydroxylation of the Kaolinite Clay Minerals Using Infrared Emission Spectroscopy.” Clays Clay Miner., 44 (5) 635–651 (1996)

Nguetnkam, JP, Kamga, R, Villiéras, F, Ekodeck, GE, Razafitianamaharavo, A, Yvon, J, “Assessment of the Surface Areas of Silica and Clay in Acid-Leached Clay Materials Using Concepts of Adsorption on Heterogeneous Surfaces.” J. Colloid Interface Sci., 289 (1) 104–115 (2005)

Volzone, C, Ortiga, J, “Removal of Gases by Thermal-Acid Leached Kaolinitic Clays: Influence of Mineralogical Composition.” Appl. Clay Sci., 32 (1–2) 87–93 (2006)

Madhusoodana, CD, Kameshima, Y, Nakajima, A, Okada, K, Kogure, T, MacKenzie, KJD, “Synthesis of high surface area al-coating mesoporous silica from calcined and acid leached kaolinites as the precursors.” J. Colloid Interface Sci., 297 (2) 724–731 (2006)

Mackenzie, KJD, Okada, K, Temuujin, J, “Nanoporous Inorganic Materials from Mineral Templates.” Curr. Appl. Phys., 4 (2–4) 167–170 (2004)

Madejová, J, Bujdák, J, Janek, M, Komadel, P, “Comparative FT-IR Study of Structural Modifications During Acid Treatment of Dioctahedral Smectites and Hectorite.” Spectrochim Acta A., 54 (10) 1397–1406 (1998)

Gámiz, E, Melgosa, M, Sánchez-Maraňón, M, Martin-Garcia, JM, Delgado, R, “Relationships Between Chemico-Mineralogical Composition and Color Properties in Selected Natural and Calcined Spanish Kaolins.” Appl. Clay Sci., 28 (1) 269–282 (2005)

Caner, E, Farnood, R, Yan, N, “Relationship Between Gloss and Surface Texture of Coated Papers.” Tappi J., 7 (4) 19–26 (2008)

Murray, M, “Kaolin applications.” In: Murray, HH (ed.) Applied Clay Mineralogy Occurrences, Processing and Application of Kaolins, Bentonites, Palygorskite-Sepiolite, and Common Clays. Elsevier, Amsterdam (2007)

Preston, JS, Elton, NJ, Legrix, A, Nutbeem, C, “The Role of Pore Density in the Setting of Offset Printing Ink on Coated Paper.” Advanced Coating Fundamentals Symposium, Tappi Press, San Diego, CA, USA, 2001

Oittinen, P, Saarelma, H, “Printing.” In: Gullichsen, J, Paulapuro, H (eds.) Papermaking Science and Technology, Vol. 13. Fapet Oy, Helsinki (2000)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Sherbiny, S., Morsy, F.A., Hassan, M.S. et al. Enhancing Egyptian kaolinite via calcination and dealumination for application in paper coating. J Coat Technol Res 12, 739–749 (2015). https://doi.org/10.1007/s11998-015-9672-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-015-9672-5