Abstract

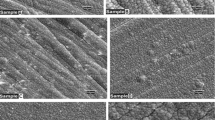

Ni–P deposits with a phosphorous content of up to 20% (wt) were obtained on AA6061 substrates by direct current electrodeposition technique from a solution containing nickel sulfate, nickel chloride, phosphorous acid, phosphoric acid, and a wetting agent (sodium lauryl sulfate). The effect of various plating parameters like current density, concentration of phosphorous acid, concentration of phosphoric acid and plating temperature on the P content of the coating as well as the rate of deposition was investigated systematically. It has been observed that the influence of current density on the P content of the deposit is largely dependent on the concentration of phosphorous acid in the plating bath. Composition, surface morphology, microstructure, and mechanical properties of the Ni–P deposits were studied using SEM, EDAX, XRD, and nanoindentation techniques. Ni–P electrodeposits with low P content in the range of 4–7 wt% of P exhibited superior microhardness of 7.74–8.57 GPa. With increasing P content in the deposit, the structure undergoes transition from crystalline to nanocrystalline and becomes amorphous above 9.14 wt% of P. Ni–P alloys with some selected compositions were subjected to heat treatment at 400°C for 1 h in a hot air oven and the resulting variation in mechanical properties was studied using nanoindentation technique.

Similar content being viewed by others

References

Wronkowska, AA, Wronkowski, A, “Optical Properties of Polycrystalline and Amorphous Ni1−xPx Layers by Ellipsometry.” J. Mater. Sci., 27 1842–1848 (1992)

Ke, S-T, Lee, J-L, Yeh, Y-M, Lee, S-J, Ger, M-D, “A Study of the Microstructure and Properties of Electroformed Ni–P Model Insert.” Key Eng. Mater., 364–366 232–236 (2008)

Boylan, K, Ostrander, D, Erb, U, Paulumbo, G, Aust, KT, “An In Situ TEM Study of the Thermal Stability of Nanocrystalline Ni–P.” Scripta Metall. Mater., 25 2711–2716 (1991)

Marshall, GW, Lewis, DB, Dodds, BE, “Electroless Deposition of Ni–P Alloys with and without the Use of Superimposed Pulsed Current.” Surf. Coat. Technol., 53 223–230 (1992)

Lashmore, DS, Weinroth, JF, “Pulse Electrodeposition of Nickel–Phosphorous Metallic Glass Alloys.” Plat. Surf. Finish., 69 72–76 (1982)

Habazaki, H, Lu, YP, Kawashima, A, Asami, K, Hashimoto, K, “The Effects of Structural Relaxation and Crystallization on the Corrosion Behaviour of Electrodeposited Amorphous Ni–P Alloys.” Corros. Sci., 32 (11) 1227–1235 (1991)

Jeong, DH, Erb, U, Aust, KT, Palumbo, G, “The Relationship Between Hardness and Abrasive Wear Resistance of Electrodeposited Nanocrystalline Ni–P Coatings.” Scripta Mater., 48 1067–1072 (2003)

Dini, JW, Donaldson, RR, Syn, CK, Sugg, DJ, “Diamond Tool Wear of Electrodeposited Nickel–Phosphorous Alloy”. SUR/FIN ‘90: 77th American Electroplaters and Surface Finishers Society (AESF) Annual Technical Conference, Boston, MA, USA, 9–12 July 1990.

Crousier, J, Hanane, Z, Crousier, JP, “A Cyclic Voltammetry Study of the Ni–P Electrodeposition.” Electrochim. Acta, 38 (2/3) 261–266 (1993)

Bredael, E, Celis, JP, Roos, JR, “NiP Electrodeposition on a Rotating-Disc Electrode and in a Jet Cell: Relationship Between Plating Parameters and Structural Characteristics.” Surf. Coat. Technol., 58 63–71 (1993)

Shervedani, RK, Lasia, A, “Studies of the Hydrogen Evolution Reaction on Ni–P Electrodes.” J. Electrochem. Soc., 144 (2) 511–519 (1997)

Budniok, A, Serek, A, “New Electrode Materials Containing Titanium Powder in an Amorphous Matrix of Ni–P.” Key Eng. Mater., 230–232 213–217 (2002)

Kobayashi, S, Kashikura, Y, “Grain Growth and Mechanical Properties of Electrodeposited Nanocrystalline Nickel–4.4 mass% Phosphorous Alloy.” Mater. Sci. Eng., A, 358 76–83 (2003)

Bredael, E, Blanpain, B, Celis, JP, Roos, JR, “On the Amorphous and Crystalline State of Electrodeposited Nickel–Phosphorous Coatings.” J. Electrochem. Soc., 141 (1) 294–299 (1994)

Peeters, P, Hoorn, GVD, Daenen, T, Kurowski, A, Staikov, G, “Properties of Electroless and Electroplated Ni–P and Its Application in Microgalvanics.” Electrochim. Acta, 47 161–169 (2001)

Ng, PK, Snyder, DD, LaSala, J, “Structure and Crystallization Of Nickel–Phosphorous Alloys Prepared by High-Rate Electrodeposition.” J. Electrochem. Soc., 135 (6) 1376–1381 (1988)

Daly, BP, Barry, FJ, “Electrochemical Nickel–Phosphorous Alloy Formation.” Int. Mater. Rev., 48 (5) 326–338 (2003)

Narayan, R, Mungole, MN, “Electrodeposition of Ni–P Alloy Coatings.” Surf. Technol., 24 233–239 (1985)

Bagley, BG, Turnbull, D, “The Preparation and Crystallization Behaviour of Amorphous Nickel–Phosphorous Thin Films.” Acta Metall., 18 (8) 857–862 (1970)

Habazaki, H, Ding, S-Q, Kawashima, A, Asami, K, Hashimoto, K, Inoue, A, Masumoto, T, “The Anodic Behaviour of Amorphous Ni–19P Alloys in Different Amorphous States.” Corros. Sci., 29 (11–12) 1319–1328 (1989)

Saxena, V, Uma Rani, R, Sharma, AK, “Studies on Ultra High Solar Absorber Black Electroless Nickel Coatings on Aluminium Alloys for Space Applications.” Surf. Coat. Technol., 201 (3–4) 855–862 (2006)

Brenner, A, Couch, DE, Williams, EK, “Electrodeposition of Phosphorous with Nickel or Cobalt.” J. Res. Natl. Bur. Stand., 44 109–122 (1950)

Brenner, A, Electrodeposition of Alloys Principles and Practice, Vols. 1 & 2. Academic Press, New York, 1963

Engelhaupt, DE, “Electrodeposited Nickel–Phosphorous.” Plat. Surf. Finish, 96 22–28 (2009)

Li, L, Zhang, Y, Deng, S, Chen, Y, “Effect of Ammonium on Low Temperature Electrodeposition of Ni–P Alloys.” Mater. Lett., 57 3444–3448 (2003)

Mc Mohan, G, Erb, U, “Structural Transitions in Electroplated Ni–P Alloys.” J. Mater. Sci. Lett., 8 865–868 (1989)

Toth-Kadar, E, Bakonyi, I, Solyom, A, Hering, J, Konczos, G, “Preparation and Characterization of Electrodeposited Amorphous Ni–P Alloys.” Surf. Coat. Technol., 31 31–43 (1987)

Lin, CS, Lee, CY, Chen, FJ, Li, WC, “Structural Evolution and Internal Stress of Nickel–Phosphorous Electrodeposits.” J. Electrochem. Soc., 152 (6) 370–375 (2005)

Seo, MH, Kim, JS, Hwang, WS, Kim, DJ, Hwang, SS, Chun, BS, “Characteristics of Ni–P Alloy Electrodeposited from a Sulfamate Bath.” Surf. Coat. Technol., 176 135–140 (2004)

Morikawa, T, Nakade, T, Yokoi, M, Fukumoto, Y, Iwakura, C, “Electrodeposition of Ni–P Alloys from Ni-Citrate Bath.” Electrochim. Acta, 42 (1) 115–118 (1997)

Feng, L, “Commercial Process for Electroplating Nickel–Phosphorous Coatings.” US Patent 20040031694, 2004

Lin, CS, Lee, CY, Chen, FJ, Chien, CT, Lin, PL, Chung, WC, “Electrodeposition of Nickel–Phosphorous Alloy from Sulfamate Baths with Improved Current Efficiency.” J. Electrochem. Soc., 153 (6) 387–392 (2006)

Engelhaupt, DE, Ramsey, BD, “Nickel Cobalt Phosphorous Low Stress Electroplating.” US Patent 6406611 B1, 2002

Masuda, J, “Die for Press Forming of Glass and Manufacturing Method Thereof.” US Patent 20090178737, 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pillai, A.M., Rajendra, A. & Sharma, A.K. Electrodeposited nickel–phosphorous (Ni–P) alloy coating: an in-depth study of its preparation, properties, and structural transitions. J Coat Technol Res 9, 785–797 (2012). https://doi.org/10.1007/s11998-012-9411-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-012-9411-0