Abstract

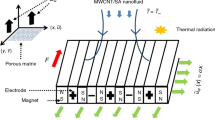

In order to explore the impact of anode replacement on heat transfer and magneto-hydrodynamic flow in aluminum smelting cells, a transient three-dimensional coupled mathematical model has been developed. With a steady state magnetic field, an electrical potential approach was used to obtain electromagnetic fields. Joule heating and Lorentz force, which were the source terms in the energy and momentum equations, were updated at each iteration. The phase change of molten electrolyte (bath) was modeled by an enthalpy-based technique in which the mushy zone was treated as a porous medium with porosity equal to the liquid fraction. A reasonable agreement between the test data and simulated results was achieved. Under normal conditions, the bath at the middle of the cell is hotter, while becoming colder at the four corners. Due to the heat extracted from the bath, the temperature of the new cold anode increases over time. The temperature of the bath under the new cold anode therefore quickly drops, resulting in a decrease of the electrical conductivity. More Joule effect is created. In addition, the bath under the new cold anode gradually freezes and flows more slowly. The temperature of the new anode located at the middle of the cell rises faster because of the warmer bath. It is easier to eliminate the effect of anode change when it occurs in the middle of the cell.

Similar content being viewed by others

Abbreviations

- \( \vec{A} \) :

-

Magnetic potential vector

- \( A_{\text{mush}} \) :

-

Mushy zone constant

- \( \vec{B} \) :

-

Magnetic flux density (T)

- \( c_{\text{p}} \) :

-

Heatcapacity [J/(kg K)]

- \( \vec{F}_{\text{e}} \) :

-

Lorentz force (N/m3)

- \( \vec{F}_{\text{b}} \) :

-

Buoyancy force (N/m3)

- \( \vec{F}_{\text{p}} \) :

-

Pressure drop (m/s)

- \( f_{\text{l}} \) :

-

Liquid fraction

- \( H \) :

-

Enthalpy (J/kg)

- \( h \) :

-

Sensible enthalpy (J/kg)

- \( h_{\text{ref}} \) :

-

Reference enthalpy (J/kg)

- \( \vec{J} \) :

-

Current density (A/m2)

- \( k_{\text{eff}} \) :

-

Effective thermal conductivity [W/(m K)]

- \( L \) :

-

Latent heat (J/kg)

- \( p \) :

-

Pressure (Pa)

- \( Q_{\text{J}} \) :

-

Joule heating (W/m3)

- \( T \) :

-

Temperature (K)

- \( T_{\text{ref}} \) :

-

Reference temperature (K)

- \( T_{\text{l}} \) :

-

Liquidus temperature (K)

- \( T_{\text{s}} \) :

-

Solidus temperature (K)

- \( t \) :

-

Time (s)

- \( \vec{v} \) :

-

Velocity (m/s)

- \( \mu_{0} \) :

-

Vacuum permittivity of metal (F/m)

- \( \rho \) :

-

Density (kg/m3)

- \( \sigma \) :

-

Electrical conductivity [1/(Ω m)]

- \( \varphi \) :

-

Electric potential (V)

References

S. Das, JOM 64, 285 (2012).

N.A. Warner, Metall. Mater. Trans. B 39, 246 (2008).

G.P. Tarcy, H. Kvande, and A. Tabereaux, JOM 63, 101 (2011).

P. Desclaux, Metall. Mater. Trans. B 32B, 743 (2001).

J. Zoric, J. Thonstad, and T. Haarberg, Metall. Mater. Trans. B 30B, 341 (1999).

M.P. Taylor, W.D. Zhang, V. Wills, and S. Schmid, Trans. IChemE. 74, 913 (1996).

J.M. Purdie, M. Bilek, and M.P. Taylor, Light Metals (Warrendale, PA: TMS, 1993), pp. 335–360.

C.Y. Cheung, C. Menictas, J. Bao, M. Skyllas-Kazacos, and B.J. Welch, AIChE J. 59, 1544 (2013).

M. Dupuis and V. Bojarevics, Light Metals (Warrendale, PA: TMS, 2005), pp. 449–454.

Y. Safa, M. Flueck, and J. Rappaz, Appl. Math. Model. 33, 1479 (2009).

R. Kalter, M.J. Tummers, S. Kenjereš, B.W. Righolt, and C.R. Kleijn, Int. J. Heat Fluid Flow 47, 113 (2014).

W. Bian, P. Vasseur, E. Bilgen, and F. Meng, Int. J. Heat Fluid Flow 17, 36 (1996).

R. Kumar and A. Dewan, Int. J. Heat Mass Transf. 72, 680 (2014).

R. Dutta, A. Dewan, and B. Srinivasan, Int. J. Heat Mass Transf. 65, 750 (2013).

S. Bouabdallah and R. Bessaïh, Int. J. Heat Fluid Flow 37, 154 (2012).

T.Q. Li, C.S. Wu, Y.H. Feng, and L.C. Zheng, Int. J. Heat Fluid Flow 34, 117 (2012).

R. Banki, H. Hoteit, and A. Firoozabadi, Int. J. Heat Mass Transf. 51, 3387 (2008).

D.A. Bograchev and S. Martemianov, Int. J. Heat Mass Transf. 54, 3024 (2011).

O. Zikanov, A. Thess, P.A. Davidson, and D.P. Ziegler, Metall. Mater. Trans. B 31, 1541 (2000).

Q. Wang, B.K. Li, Z. He, and N.X. Feng, Metall. Mater. Trans. B 45, 272 (2014).

M.P. Taylor, G.L. Johnson, E.W. Andrews, and B.J. Welch, Light Metals (Warrendale, PA: TMS, 2004), pp. 199–206.

R.J. Zhao, L. Gosselin, A. Ousegui, M. Fafard, and D.P. Ziegler, Numer. Heat Transf. A 64, 317 (2013).

M.A. Cooksey, M.P. Taylor, and J.J.J. Chen, JOM 60, 51 (2008).

B. Pekmen and M. Tezer-Sezgin, Int. J. Heat Mass Transf. 71, 172 (2014).

K. Vékony and L.I. Kiss, Metall. Mater. Trans. B 43, 1086 (2012).

Z.S. Kolenda, J. Nowakowski, and P. Oblakowski, Int. J. Heat Mass Tran. 24, 891 (1981).

K. Azari, H. Alamdari, G. Aryanpour, D.P. Ziegler, D. Picard, and M. Fafard, Powder Technol. 246, 650 (2013).

G. Choudhary, Electrochem. Soc. 49, 5111 (1973).

Y. Su, J.H. Davidson, and F.A. Kulacki, Int. J. Heat Fluid Flow 44, 95 (2013).

J.P. Peng, Industrial test study on newly structured cathode aluminum reduction cell (Ph.D. thesis, Northeastern University, Shenyang, China, 2009).

Z.Q. Wang, Industrial experimental study of aluminum reduction cells potline with a new type of cathode design (Ph.D. thesis, Northeastern University, Shenyang, China, 2010).

Acknowledgement

The authors’ gratitude goes to the National Natural Science Foundation of People’s Republic of China (51434005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Li, B. & Fafard, M. Effect of Anode Change on Heat Transfer and Magneto-hydrodynamic Flow in Aluminum Reduction Cell. JOM 68, 610–622 (2016). https://doi.org/10.1007/s11837-015-1714-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1714-z