Abstract

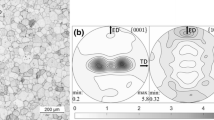

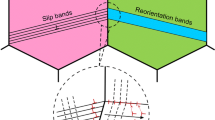

We present results of texture characterization and predictions of a multiscale physically based constitutive law developed to predict the mechanical response and texture evolution of body-centered cubic metals. The model is unique in the sense that single crystal deformation results not only from the resolved shear stress along the direction of slip (Schmid law) but also from shear stresses resolved along directions orthogonal to the slip direction as well as the three normal stress components (non-Schmid effects). The single crystal model is implemented into a visco-plastic self-consistent homogenization scheme containing a hardening law for crystallographic slip. The polycrystal model is calibrated using a set of mechanical test data collected on a tantalum-tungsten alloy, Ta-10W, in tension and compression and pure tantalum, Ta, in tension, compression, and cross-rolling. We demonstrate that the model effectively captures the texture evolution in all cases. We show that alloying has the effect of increasing the dislocation friction stress, the trapping rate of dislocations, and activation barrier for recovery.

Similar content being viewed by others

References

H. Matsuno, A. Yokoyama, F. Watari, M. Uo, and T. Kawasaki, Biomaterials 22, 1253 (2001).

R. Arsenault and A. Lawley, Philos. Mag. 15, 549 (1967).

S. Chen and G. Gray, Metall. Mater. Trans. A 27, 2994 (1996).

G.T. Gray and K.S. Vecchio, Metall. Mater. Trans. A 26, 2555 (1995).

G.T. Gray III, Annu. Rev. Mater. Res. 42, 285 (2012).

J. Clark Jr, R. Garrett Jr, T. Jungling, and R. Asfahani, Metall. Mater. Trans. A 22, 2959 (1991).

J. Christian, Metall. Trans. A 14, 1237 (1983).

R. Foxall and C. Statham, Acta Metall. 18, 1147 (1970).

L. Yang, P. Söderlind, and J.A. Moriarty, Philos. Mag. A 81, 1355 (2001).

T. Mitchell and W. Spitzig, Acta Metall. 13, 1169 (1965).

M. Ardeljan, I.J. Beyerlein, and M. Knezevic, J. Mech. Phys. Solids 66, 16 (2014).

M. Ardeljan, M. Knezevic, T. Nizolek, I.J. Beyerlein, N.A. Mara, and T.M. Pollock, Int. J. Plast. 74, 35 (2015).

M. Knezevic, M. Zecevic, I.J. Beyerlein, J.F. Bingert, and R.J. McCabe, Acta Mater. 88, 55 (2015).

M. Knezevic, J.S. Carpenter, M.L. Lovato, and R.J. McCabe, Acta Mater. 63, 162 (2014).

M. Knezevic, I.J. Beyerlein, M.L. Lovato, C.N. Tomé, A.W. Richards, and R.J. McCabe, Int. J. Plast. 62, 93 (2014).

A. Bhattacharyya, M. Knezevic, and M. Abouaf, Metall. Mater. Trans. A 46, 1085 (2015).

R.A. Lebensohn and C.N. Tomé, Acta Metall. Mater. 41, 2611 (1993).

M. Knezevic, R.J. McCabe, R.A. Lebensohn, C.N. Tomé, C. Liu, M.L. Lovato, and B. Mihaila, J. Mech. Phys. Solids 61, 2034 (2013).

H. Lim, C.R. Weinberger, C.C. Battaile, and T.E. Buchheit, Modell. Simul. Mater. Sci. Eng. 21, 045015 (2013).

M. Knezevic, T. Nizolek, M. Ardeljan, I.J. Beyerlein, N.A. Mara, and T.M. Pollock, Int. J. Plast. 57, 16 (2014).

Acknowledgements

Support for this research was provided by H.C. Starck, Newton, MA, 02461, USA. I. J. Beyerlein would like to acknowledge support by a Laboratory Directed Research and Development Program Award Number 20140348ER.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Knezevic, M., Zecevic, M., Beyerlein, I.J. et al. Predicting Texture Evolution in Ta and Ta-10W Alloys Using Polycrystal Plasticity. JOM 67, 2670–2674 (2015). https://doi.org/10.1007/s11837-015-1613-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1613-3