Abstract

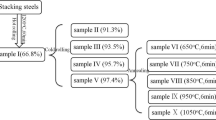

Steel/Cu/Al laminated sheets were fabricated by two-pass hot rolling to improve the mechanical properties of steel/Al sheets. The bonding properties and deformability of the steel/Cu/Al sheets were studied. Steel/Al and steel/Cu/Al samples were rolled at 350°C for 15 min with the first-pass reduction of 40%, and then heated at 600°C for 5 min with different reductions. It was found that the steel/Cu/Al samples rolled by the second-pass reduction of 85% could endure the maximum 90° bend cycle times of 45, exhibiting excellent fatigue resistance as well as deformability. The steel/Al samples could only reach the maximum 90° bend cycle times of 20. Furthermore, the scanning electron microscope, energy-dispersive spectrometer, and electron backscattered diffraction results showed that the preferred growth orientations of Cu, Al4Cu9, and Al2Cu on the steel/Cu/Al laminated sheets are {−1, 1, 2} 〈1, −1, 1〉, {1, 0, 0} 〈0, 1, 0〉 and {−1, 1, 2} 〈1, −1, 1〉 {1, 1, 0} 〈0, 0, 1〉. The orientation relationships between Cu and Al2Cu are {1, 1, 0}(fcc)//{1, 1, 0}(bct) and {1, 1, 1}(fcc)//{1, 1, 1}(bct). The improved bonding property and excellent fatigue resistance as well as deformability were mainly ascribed to the tight combination and consistent deformability across steel, Al, and the transition layers (Cu, Al4Cu9, and Al2Cu).

Similar content being viewed by others

References

K. Murakamia, N. Nishidaa, K. Osamurab, Y. Tomotac, and T. Suzukic, Acta Mater. 52, 2173 (2004).

J. Tao and H. Jing tao, Adv. Mater. Res. 905, 123 (2014).

K. Bhanumurthy, W. Krauss, and J. Konys, Fusion Sci. Technol. 65, 262 (2014).

M. Vedat Akdeniz, A.O. Mekhrabov, and T. Yilmaz, Scr. Metall. Mater. 31, 1723 (1994).

S. Qun Ling and S. Yong, Trans. Mater. Heat Treat. 33, 15 (2012).

Y. Kojima, Mater. Sci. Forum 350–351, 3 (2000).

Z. Li Ming and Z. Zhao Dong, Scr. Mater. 58, 283 (2008).

Z. Li Qiang, Y. Ping, C. Min, and L. Ning Bo, Appl. Surf. Sci. 258, 3975 (2012).

V. Jindal and V.C. Srivastava, J. Mater. Process. Technol. 95, 88 (2008).

M. Shinya, K. Shinji, and S. Akikazu, Mater. Sci. Eng., A 400, 300 (2005).

Y. Ping, Application and Technology of EBSD, 1st ed. (Beijing: Metallurgical Industry Press, 2007), pp. 160–161.

R. Bonnet and M. Loubradou, Phys. Status Solidi A 194, 173 (2002).

B. Yang, Y.T. Zhou, D. Chen, and X.L. Ma, Sci. Rep. 3, 1039 (2013). doi:10.1038/s01039.

D. Galy and L. Boulanger, J. Mater. Sci. 30, 1766 (1995).

M. Wei Min, Y. Ping, and C. Leng, Principle of Texture Analysis and its Measurement Technology of Materials, 1st ed. (Beijing: Metallurgical Industry Press, 2008), pp. 122–124.

R. Zhang, Y.H. Tian, C.J. Hang, B.L. Liu, and C.Q. Wang, Mater. Lett. 110, 137 (2013).

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant No. 51201112), the Specialized Research Fund for the Doctoral Program of Higher Education (Grant No. 20121402120004), Natural Science Foundation of Shanxi (Grant Nos. 2013021013-3 and 2012011021-2).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, A., Liu, X., Shi, Q. et al. Effects of the Formation of Al x Cu y Gradient Interfaces on Mechanical Property of Steel/Al Laminated Sheets by Introducing Cu Binding-Sheets. JOM 67, 1436–1442 (2015). https://doi.org/10.1007/s11837-015-1398-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1398-4