Abstract

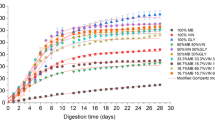

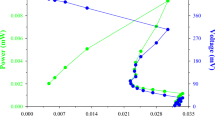

Two different aqueous amine solutions were applied to CO2 removal from simulated biogas in a lab.-scale continuous absorption process that can handle 5Nm3/hr of gas treatment. The effects of the gas-to-liquid ratio in the absorber and of the temperature of the reboiler on the CO2 removal were analyzed in aqueous MEA and AMP solutions. Since the CO2 loading ratio of AMP solutions is larger than that of MEA solutions for the same absorbent concentration, the AMP solutions have higher CO2 removal efficiency than that of MEA solutions for the same gas-to-liquid ratio and reboiler temperature. Also, the 30 wt% MEA solution has a higher CO2 removal efficiency than that of the 20 wt% MEA solution at the same gas-to-liquid ratio and reboiler temperature. To evaluate the feasibility of biogas upgrading, a commercial simulator, Aspen Plus®, was used to analyze the effects of absorbent concentration, absorbent flow rate at the absorption column, and absorber height on CO2 removal and CH4 purity; the regeneration energy was also evaluated. The results were applied to the design of a pilot-scale biogas upgrading plant that can handle 10,000Nm3/day of biogas treatment.

Similar content being viewed by others

References

M. S. Horikawa, M. L. Rossi, M. L. Gimenes, C. M. M. Costa and M. G. C. da Silva, Brazilian J. Chem. Eng., 21, 415 (2004).

N. Abatzoglou and S. Boivin, Biofuels Bioprod Biorefin., 3, 42 (2009).

H. Yang, Z. Xu, M. Fan, R. Gupta, R. B. Slimane and A. E. Bland, J. Environ. Sci., 20, 14 (2008).

E. J. Granite and T. O’Brien, Fuel Process Technol., 86, 1423 (2005).

N. Tippayawong and P. Thanompongchart, Energy, 35, 4531 (2010).

E. I. Privalova, P. Maki-Arvela, K. Eranen, A. K. Avetisov, J. P. Mikkola and D. Yu. Murzin, Chem. Eng. Technol., 36, 740 (2013).

C. H. Yu, C. H. Huang and C. S. Tan, Aerosol Air Quality Res., 12, 745 (2012).

W. J. Choi, J. B. Seo, S. Y. Jang, J. H. Jung and K. J. Oh, J. Environ. Sci., 21, 907 (2009).

Y. E. Kim, J. A. Lim, S. K. Jeong, Y. I. Yoon, S. T. Bae and S. C. Nam, Bull. Korean Chem. Soc., 34, 783 (2013).

U. E. Aronu, S. Gondal, E. T. Hessen, T. Haug-Wargerg, A. Hartono, K. A. Hoff and H. F. Svendsen, Chem. Eng. Sci., 66, 6393 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper is reported in the 11th China-Korea Clean Energy Workshop.

Rights and permissions

About this article

Cite this article

Park, Y.C., Lee, JS., Moon, JH. et al. Performance comparison of aqueous MEA and AMP solutions for biogas upgrading. Korean J. Chem. Eng. 34, 921–927 (2017). https://doi.org/10.1007/s11814-016-0346-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-016-0346-5