Abstract

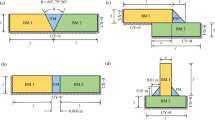

The simulation of heat flow, residual stress, and thermal distortion developed in A36 steel plate using a known volume of Zn50 brazing alloy for torch brazing technique is presented in this paper. FEHT software and GTstrudle codes were used for the heat transfer and residual stress simulation, respectively. The result of the heat flow simulation showed excessive cooling at the joints corner following convective heat loss to the ambient and maximum heat flux gradient thereby making the joint predisposed to underfill. Also the von misses stress and strain distribution in the plate showed that the residual stress is compressive and is limiting at 1800 N/mm2, localized in the joint. This is a basic understanding for impedance to thermally induced cracking.

Similar content being viewed by others

References

S.C. Nwigbo, S.O. Mbam, C.U. Atuanya, Development of Zn50 Brazing Alloy for joining mild steel and mild steel (SAE1018). Tribol. Ind. 36(3), 326–338 (2014)

J. Madeni, Investigation of liquid filler metal flow process through a brazed gap. Masters Degree thesis, Colorado school of mines. http://digitool.library.colostate.edu///exlibris/dtl/d31/apachemedia/L2V4bGlicmlz2R0bC9kM18xL2FwYYWNoZV9tZWRpYs8yMT12N. Accessed 06 Jun 2014

U. Sreedhar, C. V. Krishnamurthy, K. Balasubramiam, V. D. Raghupathy, S. Rarishankar, Modelling and simulation of temperature prediction in welding using infrared thermography, in Proceedings of National Seminar and Exhibitions on Non-destructive Evaluation, pp. 396–400 (2009)

S. Kou, Y. Le, Heat flow during autogenous GTA welding of pipes. Metall. Trans. A 15A, 1165–1171 (1984)

C. Gabriela, Thermal analysis of two brazed alloys to improve the performance of a contactor during the temperature rise test. Masters Thesis, Rensselaer Polytechnic Institute 2010. http://www.ewp.rpi.edu/hartford/~Ernesto/SPR/Contreras-FinalReport.pdf. Accessed 06 Jun 2014

W. Jiang, J. Gong, S. Tu, H. Chen, Finite element analysis of the effect of brazed residual stress on creep for stainless steel plate-fin structure, J. Press Vessel Technol. ASME 130, 041203, 1–7 (2008)

J. Wiese, Strength of metal to ceramic brazed joint. Masters thesis, Massachusetts institute of technology 2001. www.eagar.mit.edu/Weldlab/Disimilar/jlw-thesis.pdf. Accessed 20 Jan 2014

V. Cazaju, S. Seguy, B. Lorrain, H. Welemane, C. Prat, M. Karama, Thermal stresses in ceramics-metal composite after brazing process, University ‘politechnica’ of Bucharest Romania 2005. http://sebastien.seguy.viola.net/public/ics_05.pdf. Accessed 13 Mar 2014

H. Chen, J. Gong, L. Geng, S. Tu, Finite element prediction of residual stresses and thermal distortion in a brazed plate-fin structure. J. Press. Equip. Syst. 3, 118–124 (2005)

W. Zhuang, R. Shue, P. Chang, Finite element analysis of the residual thermal stress in a power package with two different lead. Int. J. Microcircuits Electron. Packag. 22(3), 196–202 (1999)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nwigbo, S.C., Nwoye, C.F. Thermal and Residual Stress Analysis on A36 Steel Plate Brazed with a Known Volume of Zn50 Brazing Alloy (Filler Metal). J Fail. Anal. and Preven. 15, 924–931 (2015). https://doi.org/10.1007/s11668-015-0037-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-0037-2