Abstract

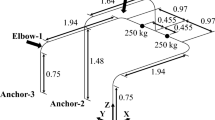

This article aims to study the plastic collapse and crack behavior of steel pressure vessels and piping using the extended finite element method (XFEM). First, the plastic collapse loads of steel cylinders under the internal pressure are predicted, and the numerical results are compared with experimental data. In addition, the computational efficiency and accuracy using different methods including the XFEM, nonlinear stabilization algorithm, and arc-length algorithm are compared. Particularly, effects of different initial crack configurations, element sizes, damage initiation, and evolution criteria on the crack behaviors are investigated. Second, the crack initiation and propagation properties of buried pipelines due to deflection in the landslide area are explored, and the numerical results are compared between testing data and current study. Besides, the effects of internal pressure, wall thickness, soil property, and width of landslide area on the critical deflection displacement of buried pipeline are studied. This research provides a fundamental support for safety evaluation and life prediction of pressurized structures.

Similar content being viewed by others

Notes

ABAQUS 6.11 documentation.

Abbreviations

- a :

-

Crack depth

- D/t ratio:

-

Ratio of diameter to thickness

- E :

-

Young’s modulus

- G :

-

Energy release rate

- G IC, G IIC, G IIIC :

-

Critical energy release rates of three fracture modes

- G C :

-

Critical equivalent energy release rates based on mixed-mode criteria

- l :

-

Crack length

- P i :

-

Internal pressure

- R m :

-

Tensile strength

- U max :

-

Maximum deflection displacement along the axial direction

- \( \sigma_{{\hbox{Max} {\text{ps}}}} \) :

-

Maximum principal stress as damage initiation criterion

References

Mathur, K.K., Needleman, A., Tvergaard, V.: Ductile failure analyses on massively parallel computers. Comput. Meth. Appl. Mech. Eng. 119(3), 283–309 (1994)

de Borst, R.: Challenges in computational materials science: multiple scales, multi-physics and evolving discontinuities. Comput. Mater. Sci. 43(1), 1–15 (2008)

ASME BPVC VIII-3. Alternative Rules for Construction of High Pressure Vessels (2010)

Liu, P.F., Zheng, J.Y., Miao, C.J.: Calculations of plastic collapse load of pressure vessel using FEA. J. Zhejiang Univ. Sci. A 9(7), 900–906 (2008)

Liu, P.F., Zheng, J.Y.: Progressive failure analysis of carbon fiber/epoxy composite laminates using continuum damage mechanics. Mater. Sci. Eng. A 485(1), 711–717 (2008)

Liu, P.F., Zheng, J.Y.: Review on Methodologies of Progressive Failure Analysis of Composite Laminates. Continuum Mechanics, Chap. 11. Nova Science Publishers, New York (2009)

Liu, P.F., Zheng, J.Y.: Recent developments on damage modeling and finite element analysis for composite laminates: a review. Mater. Design 31(8), 3825–3834 (2010)

Zheng, J.Y., Liu, P.F.: Elasto-plastic stress analysis and burst strength evaluation of Al-carbon fiber/epoxy composite cylindrical laminates. Comput. Mater. Sci. 42(3), 453–461 (2008)

Xu, P., Zheng, J.Y., Liu, P.F.: Finite element analysis of burst pressure of composite hydrogen storage vessels. Mater. Design 30(7), 2295–2301 (2009)

Siegmund, T.: A numerical study of transient fatigue crack growth by use of an irreversible cohesive zone model. Int. J. Fatigue 26(9), 929–939 (2004)

Roe, K.L., Siegmund, T.: An irreversible cohesive zone model for interface fatigue crack growth simulation. Eng. Fract. Mech. 70(2), 209–232 (2003)

Bouvard, J.L., Chaboche, J.L., Feyel, F., et al.: A cohesive zone model for fatigue and creep–fatigue crack growth in single crystal super alloys. Int. J. Fatigue 31(5), 868–879 (2009)

Liu, P.F., Hou, S.J., Chu, J.K., et al.: Finite element analysis of postbuckling and delamination of composite laminates using virtual crack closure technique. Compos. Struct. 93(6), 1549–1560 (2011)

Fawaz, S.A.: Application of the virtual crack closure technique to calculate stress intensity factors for through cracks with an elliptical crack front. Eng. Fract. Mech. 59(3), 327–342 (1998)

Servetti, G., Zhang, X.: Predicting fatigue crack growth rate in a welded butt joint: the role of effective R ratio in accounting for residual stress effect. Eng. Fract. Mech. 76(11), 1589–1602 (2009)

Belytschko, T., Black, T.: Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 45(5), 601–620 (1999)

Belytschko, T., Chen, H., Xu, J., et al.: Dynamic crack propagation based on loss of hyperbolicity and a new discontinuous enrichment. Int. J. Numer. Methods Eng. 58(12), 1873–1905 (2003)

Moës, N., Dolbow, J., Belytschko, T.: A finite element method for crack growth without remeshing. Int. J. Numer. Methods Eng. 46(1), 131–150 (1999)

Moës, N., Belytschko, T.: Extended finite element method for cohesive crack growth. Eng. Fract. Mech. 69(7), 813–833 (2002)

Sukumar, N., Moës, N., Moran, B., et al.: Extended finite element method for three-dimensional crack modeling. Int. J. Numer. Methods Eng. 48(11), 1549–1570 (2000)

Sukumar, N., Huang, Z.Y., Prévost, J.H., et al.: Partition of unity enrichment for bimaterial interface cracks. Int. J. Numer. Methods Eng. 59(8), 1075–1102 (2003)

Giner, E., Sukumar, N., Tarancón, J.E.: An Abaqus implementation of the extended finite element method. Eng. Fract. Mech. 76(3), 347–368 (2009)

Campilho, R.D.S.G., Banea, M.D., Chaves, F.J.P., et al.: eXtended finite element method for fracture characterization of adhesive joints in pure mode I. Comput. Mater. Sci. 50(4), 1543–1549 (2011)

Golewski, G.L., Golewski, P., Sadowski, T.: Numerical modelling crack propagation under Mode II fracture in plain concretes containing siliceous fly-ash additive using XFEM method. Comput. Mater. Sci. 62, 75–78 (2012)

Wang, Z.Q., Zhou, S., Zhang, J.F.: Progressive failure analysis of bolted single-lap composite joint based on extended finite element method. Mater. Design 37, 582–588 (2012)

Xu, Y.J., Yuan, H.: Applications of normal stress dominated cohesive zone models for mixed-mode crack simulation based on extended finite element methods. Eng. Fract. Mech. 78, 544–558 (2011)

Comi, C., Mariani, S., Perego, U.: An extended FE strategy for transition from continuum damage to mode I cohesive crack propagation. Int. J. Numer. Anal. Methods Geomech. 31, 213–238 (2007)

Benzeggagh, M.L., Kenane, M.: Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 56(4), 439–449 (1996)

Mojiri, S. Numerical Analysis of Cohesive Crack Growth Using Extended Finite Element Method (X-FEM). Master of Science Thesis. Institut de Recherche en Génie Civil et Méchanique, France (2010)

Liu, P.F., Zheng, J.Y., Zhang, B.J.: Failure analysis of natural gas buried X65 steel pipeline under deflection load using finite element method. Mater. Des. 31(3), 1384–1391 (2010)

Zheng, J.Y., Zhang, B.J., Liu, P.F.: Failure analysis and safety evaluation of buried pipeline due to deflection of landslide process. Eng. Fail. Anal. 25, 156–168 (2012)

BS EN 1594. Gas supply systems—Pipelines for maximum operating pressure over 16 bar—Functional requirements. British Standards Policy and Strategy Committee (2009)

ASME B31.8. Gas Transmission and Distribution Piping Systems. The American Society of Mechanical Engineers (2010)

Acknowledgement

This research is supported by the National High Technology Research and Development Program of China (863 Program, Grant No. 2012AA040103), the Special Funds for Quality Supervision Research in the Public Interest (Grant No. 201210242) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, P.F., Zhang, B.J. & Zheng, J.Y. Finite Element Analysis of Plastic Collapse and Crack Behavior of Steel Pressure Vessels and Piping Using XFEM. J Fail. Anal. and Preven. 12, 707–718 (2012). https://doi.org/10.1007/s11668-012-9623-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-012-9623-8