Abstract

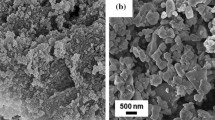

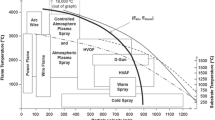

Vacuum kinetic spraying (VKS) is a promising room-temperature process to fabricate dense ceramic films. However, unfortunately, the deposition mechanism is still not clearly understood. In this respect, the critical conditions for successful deposition were investigated. Based on simulation and microstructural analysis, it was found that as the particle velocity increased, fracture mode transition from tensile fracture to shear fracture occurred and particle did not bounce off anymore above a certain velocity. Simultaneously, particle underwent shock-induced plasticity and dynamic fragmentation. The plasticity assisted to prevent the fragments from rebounding by spending the excessive kinetic energy and fragmentation is essential for fragment bonding and film growth considering that the deposition rate increased as the fraction of fragmentation increased. Accordingly, plasticity and fragmentation take a crucial role for particle deposition. In this respect, the velocity that fracture mode transition occurs is newly defined as critical velocity. Consequently, for successful deposition, the particle should at least exceed the critical velocity and thus it is very crucial for film fabrication in VKS process at room temperature.

Similar content being viewed by others

References

J. Akedo, Room Temperature Impact Consolidation (RTIC) of Fine Ceramic Powder by Aerosol Deposition Method and Applications to Microdevices, J. Therm. Spray Technol., 2008, 17(2), p 181-198

D. Hanft, J. Exner, M. Schubert, T. Stöcker, P. Fuierer, and R. Moos, An Overview of the Aerosol Deposition Method: Process Fundamentals and New Trends in Materials Applications, J. Ceram. Sci. Technol., 2015, 6, p 147-182

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858-4868

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

H. Park, J. Kwon, I. Lee, and C. Lee, Shock-Induced Plasticity and Fragmentation Phenomena During Alumina Deposition in the Vacuum Kinetic Spraying Process, Scr. Mater., 2015, 100, p 44-47

J. Kwon, H. Park, I. Lee, and C. Lee, Effect of Gas Flow Rate on Deposition Behavior of Fe-Based Amorphous Alloys in Vacuum Kinetic Spray Process, Surf. Coat. Technol., 2014, 259, p 585-593

T.J. Holmquist, D.W. Templeton, and K.D. Bishnoi, Constitutive Modeling of Aluminum Nitride for Large Strain, High-Strain Rate, and High-Pressure Applications, Int. J. Impact Eng., 2001, 25(3), p 211-231

D.S. Cronin, K. Bui, C. Kaufmann, G. McIntosh, T. Berstad, and D. Cronin, Implementation and Validation of the Johnson-Holmquist Ceramic Material Model in LS-DYNA, 4th European LS-Dyna Users Conference, 2003, pp 47-60

K. Naoe, M. Nishiki, and A. Yumoto, Relationship Between Impact Velocity of Al2O3 Particles and Deposition Efficiency in Aerosol Deposition Method, J. Therm. Spray Technol., 2013, 22(8), p 1267-1274

D.-W. Lee, H.-J. Kim, Y.-N. Kim, M.-S. Jeon, and S.-M. Nam, Substrate Hardness Dependency on Properties of Al2O3 Thick Films Grown by Aerosol Deposition, Surf. Coat. Technol., 2012, 209, p 160-168

E. Andrews and K.-S. Kim, Threshold Conditions for Dynamic Fragmentation of Ceramic Particles, Mech. Mater., 1998, 29(3), p 161-180

A. Salman, C. Biggs, J. Fu, I. Angyal, M. Szabo, and M. Hounslow, An Experimental Investigation of Particle Fragmentation Using Single Particle Impact Studies, Powder Technol., 2002, 128(1), p 36-46

E. Calvié, L. Joly-Pottuz, C. Esnouf, P. Clément, V. Garnier, J. Chevalier, Y. Jorand, A. Malchère, T. Epicier, and K. Masenelli-Varlot, Real Time TEM Observation of Alumina Ceramic Nano-Particles During Compression, J. Eur. Ceram. Soc., 2012, 32(10), p 2067-2071

G. Kanel, Behavior of Brittle Materials Under Dynamic Loading, Institute for Advanced Technology, 2000, p 1-56

J. Lankford, W. Predebon, J. Staehler, G. Subhash, B. Pletka, and C. Anderson, The Role of Plasticity as a Limiting Factor in the Compressive Failure of High Strength Ceramics, Mech. Mater., 1998, 29(3), p 205-218

J. Lankford, The Role of Dynamic Material Properties in the Performance of Ceramic Armor, Int. J. Appl. Ceram. Technol., 2004, 1(3), p 205-210

M. Munro, Evaluated Material Properties for a Sintered Alpha-Alumina, J. Am. Ceram. Soc., 1997, 80(8), p 1919-1928

D. Grady, Shock-Wave Compression of Brittle Solids, Mech. Mater., 1998, 29(3), p 181-203

H. Park, J. Kim, and C. Lee, Dynamic Fragmentation Process and Fragment Microstructure Evolution of Alumina Particles in a Vacuum Kinetic Spraying System, Scr. Mater., 2015, 108, p 72-75

A.B. Sawaoka, Shock Waves in Materials Science, Springer Science & Business Media, New York, 2012

M. Chen, J.W. McCauley, and K.J. Hemker, Shock-Induced Localized Amorphization in Boron Carbide, Science, 2003, 299(5612), p 1563-1566

S. Han, L. Zhao, Q. Jiang, and J. Lian, Deformation-Induced Localized Solid-State Amorphization in Nanocrystalline Nickel, Sci. Rep., 2012, 2, p 493

D.W. Lee, H.J. Kim, Y.H. Kim, Y.H. Yun, and S.M. Nam, Growth Process of α-Al2O3 Ceramic Films on Metal Substrates Fabricated at Room Temperature by Aerosol Deposition, J. Am. Ceram. Soc., 2011, 94(9), p 3131-3138

M.A. Meyers, A. Mishra, and D.J. Benson, Mechanical Properties of Nanocrystalline Materials, Prog. Mater Sci., 2006, 51(4), p 427-556

B.-N. Kim, K. Hiraga, K. Morita, and Y. Sakka, A High-Strain-Rate Superplastic Ceramic, Nature, 2001, 413(6853), p 288-291

F. Cao, H. Park, G. Bae, J. Heo, and C. Lee, Microstructure Evolution of Titanium Nitride Film during Vacuum Kinetic Spraying, J. Am. Ceram. Soc., 2013, 96(1), p 40-43

X. Han, L. Wang, Y. Yue, and Z. Zhang, In Situ Atomic Scale Mechanical Microscopy Discovering the Atomistic Mechanisms of Plasticity in Nano-Single Crystals and Grain Rotation in Polycrystalline Metals, Ultramicroscopy, 2015, 151, p 94-100

M. Murayama, J. Howe, H. Hidaka, and S. Takaki, Atomic-Level Observation of Disclination Dipoles in Mechanically Milled, Nanocrystalline Fe, Science, 2002, 295(5564), p 2433-2435

A.K. Mukhopadhyay, K.D. Joshi, A. Dey, R. Chakraborty, A. Rav, A.K. Mandal, J. Ghosh, S. Bysakh, S.K. Biswas, and S.C. Gupta, Nanoindentation of Shock Deformed Alumina, Mater. Sci. Eng. A, 2010, 527(24), p 6478-6483

M. Schubert, J. Exner, and R. Moos, Influence of Carrier Gas Composition on the Stress of Al2O3 Coatings Prepared by the Aerosol Deposition Method, Materials, 2014, 7(8), p 5633-5642

Acknowledgment

This work was supported by a grant from the National Research Foundation of Korea (NRF) funded by the Korean government (MEST) (NRF-2014R1A2A2A05007633).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, H., Kim, J., Lee, S.B. et al. Correlation of Fracture Mode Transition of Ceramic Particle with Critical Velocity for Successful Deposition in Vacuum Kinetic Spraying Process. J Therm Spray Tech 26, 327–339 (2017). https://doi.org/10.1007/s11666-016-0516-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0516-3