Abstract

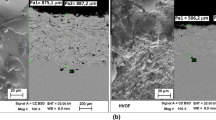

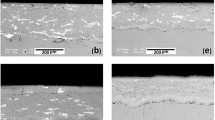

This paper studies the microstructure, sliding wear behavior and corrosion resistance of high-velocity oxygen fuel (HVOF)-sprayed FeVCrC-based coatings. Various process parameters were tested to evaluate their effects on the coating properties, which were also compared to those of HVOF-sprayed NiCrBSi and Stellite-6 coatings. The Fe alloy coatings are composed of flattened splats, originating from molten droplets and consisting of a super-saturated solid solution, together with rounded particles, coming from partially unmolten material and containing V- and Fe-based carbide precipitates. All process parameters, apart from “extreme” settings with excess comburent in the flame, produce dense coatings, indicating that the feedstock powder is quite easily processable by HVOF. These coatings, with a microhardness of 650-750 HV0.3, exhibit wear rates of ≈2 × 10−6 mm3/(Nm) in ball-on-disk tests against sintered Al2O3 spheres. They perform far better than the reference coatings, and better than other Fe- and Ni-based alloy coatings tested in previous research. On the other hand, the corrosion resistance of the coating material (tested by electrochemical polarization in 0.1 M HCl solution) is quite low. Even in the absence of interconnected porosity, this results in extensive, selective damage to the Fe-based matrix. This coating material is therefore unadvisable for severely corrosive environments.

Similar content being viewed by others

References

D. Lee, Wear-Resistant Coatings, ASM Handbook Volume 5A: Thermal Spray Technology, R.C. Tucker Jr., Ed., (Materals Park, OH, USA), ASM International, 2013, p 253-256.

D.W. Wheeler and R.J.K. Wood, Erosion of Hard Surface Coatings for Use in Offshore Gate Valves, Wear, 2005, 258(1-4 SPEC. ISS.), p 526-536

A.C. Savarimuthu, H.F. Taber, I. Megat, J.R. Shadley, E.F. Rybicki, W.C. Cornell, W.A. Emery, D.A. Somerville, and J.D. Nuse, Sliding Wear Behavior of Tungsten Carbide Thermal Spray Coatings for Replacement of Chromium Electroplate in Aircraft Applications, J. Therm. Spray Technol., 2001, 10(3), p 502-510

A. Vackel, G. Dwivedi, and S. Sampath, Structurally integrated, damage-tolerant, thermal spray coatings, JOM, 2015, 67(7), p 1540-1553

L. Moskowitz and K. Trelewicz, HVOF Coatings for Heavy-Wear, High-Impact Applications, J. Therm. Spray Technol., 1997, 6(3), p 294-299

A. Kumar, J. Boy, R. Zatorski, and L.D. Stephenson, Thermal Spray and Weld Repair Alloys for the Repair of Cavitation Damage in Turbines and Pumps: A Technical Note, J. Therm. Spray Technol., 2005, 14(2), p 177-182

L. Vernhes, D.A. Lee, D. Poirier, D. Li, and J.E. Klemberg-Sapieha, HVOF Coating Case Study for Power Plant Process Control Ball Valve Application, J. Therm. Spray Technol., 2013, 22(7), p 1184-1192

A. Edrisy, A.T. Alpas, and T. Perry, Wear Mechanism Maps for Thermal-Spray Steel Coatings, Metall. Mater. Trans. A, 2005, 36(10), p 2737-2750

S.L. Zhang, C.X. Li, and C.J. Li, Chemical Compatibility and Properties of Suspension Plasma-Sprayed SrTiO3-Based Anodes for Intermediate-Temperature Solid Oxide Fuel Cells, J. Power Sources, 2014, 264, p 195-205

D.J. Branagan, W.D. Swank, and B.E. Meacham, Meacham, Maximizing the Glass Fraction in Iron-Based High Velocity Oxy-Fuel Coatings, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2009, 40(6), p 1306-1313

A. Milanti, H. Koivuluoto, P. Vuoristo, G. Bolelli, F. Bozza, and L. Lusvarghi, Microstructural Characteristics and Tribological Behavior of HVOF-Sprayed Novel Fe-Based Alloy Coatings, Coatings, 2014, 4(1), p 98-120

A. Milanti, H. Koivuluoto, P. Vuoristo, G. Bolelli, F. Bozza, and L. Lusvarghi, “Wear and Corrosion Resistance of High-Velocity Oxygen-Fuel Sprayed Iron-Based Composite Coatings,” Proceedings of ASME 2013 International Mechanical Engineering Congress and Exposition, Volume 11: Emerging Technologies, (San Diego, CA, USA), ASME, 2013, p IMECE2013-63397

G. Bolelli, B. Bonferroni, J. Laurila, L. Lusvarghi, A. Milanti, K. Niemi, and P. Vuoristo, Micromechanical Properties and Sliding Wear Behaviour of HVOF-Sprayed Fe-Based Alloy Coatings, Wear, 2012, 276-277, p 29-47

M.O. Speidel, Nitrogen Containing Austenitic Stainless Steels, Materwiss. Werksttech., 2006, 37(10), p 875-880

K.R. Stollery, Mineral Depletion with Cost as the Extraction Limit: A Model Applied to the Behavior of Prices in the Nickel Industry, J. Environ. Econ. Manag., 1983, 10, p 151-165

International Nickel Study Group—Production, Usage and Prices. http://www.insg.org/prodnickel.aspx. Accessed 6 August 2015

K. Eckartz, C.S. Sartorius, L. Tercero Espinoza, M.E. Anta Espada, J. Bachér, A. Bierwirth, E. Bouyer, A. Brunot, J. Etxaniz, N. Fernqvist, G. Garcia, D. Gardner, C. Gonzalez, P. Holgersson, O. Karvan, E. Lindahl, A. Lopez, P. Menger, A. Morales Perez, F. Norefjall, N. Olivieri, E. Rietveld, B. Serrano, M. Thomtén, and C. Van Der Ejik, “CRM_InnoNet Deliverable Report D3.2: Critical Raw Materials Substitution Policies—Country Profiles—April 2015,” (Karlsruhe, Germany), 2015

L. Tercero Espinoza, T. Hummen, A. Brunot, A. Hovestad, I. Pena Garay, D. Velte, J. Smuk, J. Todorovic, C. Van Der Ejik, and C. Joce, “CRM InnoNet Report: Critical Raw Materials Substitution Profiles—Revised May 2015,” (Karlsruhe, Germany), 2015

P. Sommer, V.S. Rotter, and M. Ueberschaar, Battery Related Cobalt and REE Flows in WEEE Treatment, Waste Manag., Elsevier Ltd, 2015

“Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), Establishing a European Chemicals Agency, Amending Directive 1999/4,” Official Journal of the European Union, 2006, p l396/1

M. De Boeck, M. Kirsch-Volders, and D. Lison, “Cobalt and Antimony: Genotoxicity and Carcinogenicity,” Mutation Research—Fundamental and Molecular Mechanisms of Mutagenesis, 2003, p 135-152.

“Industry Actions for Responsible Assessment and Classification of Cobalt Compounds,” The Cobalt Development Institute, 2013, www.cobaltreachconsortium.org/web_images//documents/One-page-statement-Industry-Actions.pdf. Accessed 5 July 2015

“NTP Technical Report on the Toxicology Studies of Cobalt Metal (CAS NO. 7440-48-4) in F344/N Rats and B6C3F1/N Mice and Toxicology and Carcinogenesis Studies of Cobalt Metal in F344/NTac Rats and B6C3F1/N Mice (Inhalation Studies)—NTP TR 567,” 2013.

K.C. Antony, Wear-Resistant Cobalt-Base Alloys, JOM J. Miner. Met. Mater. Soc., 1983, 35(2), p 52-60

N. Axén, S. Hogmark, and S. Jacobson, Friction and Wear Measurement Techniques, Modern Tribology Handbook—Volume 1, B. Bhushan, Ed., (Boca Raton, FL, USA), CRC Press, 2001, p 493-510

G. Bolelli, A. Candeli, L. Lusvarghi, A. Ravaux, K. Cazes, A. Denoirjean, S. Valette, C. Chazelas, E. Meillot, and L. Bianchi, Tribology of NiCrAlY + Al2O3 Composite Coatings by Plasma Spraying with Hybrid Feeding of Dry Powder + suspension, Wear, 2015, 344-345, p 69-85

K. Kato and K. Adachi, Wear Mechanisms, Modern Tribology Handbook—Volume 1, B. Bhushan, Ed., (Boca Raton, FL, USA), CRC Press, 2001, p 273-300

I.V. Kragelsky, M.N. Dobychin, and V.S. Kombalov, Friction and Wear: Calculation Methods, Pergamon Press, Oxford, 1977

F. Mansfeld, Electrochemical Methods of Corrosion Testing, Corrosion: Fundamentals, Testing, and Protection—ASM Handbook Vol. 13A, S.D. Cramer and B.S. Covino Jr., Eds., (Materials Park, OH, USA), ASM International, 2003, p 446-462.

E. McCafferty, Validation of Corrosion Rates Measured by the Tafel Extrapolation Method, Corros. Sci., 2005, 47(12), p 3202-3215

Y. Wang, S.L. Jiang, Y.G. Zheng, W. Ke, W.H. Sun, X.C. Chang, W.L. Hou, and J.Q. Wang, Effect of Processing Parameters on the Microstructures and Corrosion Behaviour of High-Velocity Oxy-Fuel (HVOF) Sprayed Fe-Based Amorphous Metallic Coatings, Mater. Corros., 2013, 64(9), p 801-810

W. Liu, F. Shieu, and W. Hsiao, Enhancement of Wear and Corrosion Resistance of Iron-Based Hard Coatings Deposited by High-Velocity Oxygen Fuel (HVOF) Thermal Spraying, Surf. Coat. Technol., 2014, 249, p 24-41

A. Lekatou, D. Zois, A.E. Karantzalis, and D. Grimanelis, Electrochemical Behaviour of Cermet Coatings with a Bond Coat on Al7075: Pseudopassivity, Localized Corrosion and Galvanic Effect Considerations in a Saline Environment, Corros. Sci., 2010, 52(8), p 2616-2635

S. Deshpande, S. Sampath, and H. Zhang, Mechanisms of Oxidation and Its Role in Microstructural Evolution of Metallic Thermal Spray Coatings—Case Study for Ni-Al, Surf. Coat. Technol., 2006, 200(18-19), p 5395-5406

B. Wielage, S. Schuberth, and T. Grund, Thermisches Spritzen Vanadiumkarbidverstärkter Eisenbasisschichten, Materwiss. Werksttech., 2008, 39(1), p 48-51

J. Nohava, B. Bonferroni, G. Bolelli, and L. Lusvarghi, Interesting Aspects of Indentation and Scratch Methods for Characterization of Thermally-Sprayed Coatings, Surf. Coat. Technol., 2010, 205(4), p 1127-1131

N. Margadant, J. Neuenschwander, S. Stauss, H. Kaps, A. Kulkarni, J. Matejicek, and G. Rössler, Impact of Probing Volume from Different Mechanical Measurement Methods on Elastic Properties of Thermally Sprayed Ni-Based Coatings on a Mesoscopic Scale, Surf. Coat. Technol., 2006, 200(8), p 2805-2820

Š. Houdková, O. Bláhová, F. Zahálka, and M. Kašparová, The Instrumented Indentation Study of HVOF-Sprayed Hardmetal Coatings, J. Therm. Spray Technol., 2011, 21(1), p 77-85

Š. Houdková, E. Smazalová, O. Bláhová, and M. Vostřák, Mechanical Properties of HVOF Sprayed, Flame and Laser Remelted NiCrBSi Coatings, Key Eng. Mater., 2014, 606, p 179-182

M.P. Planche, H. Liao, B. Normand, and C. Coddet, Relationships between NiCrBSi Particle Characteristics and Corresponding Coating Properties Using Different Thermal Spraying Processes, Surf. Coat. Technol., 2005, 200(7), p 2465-2473

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Characterisations of HVOF Sprayed NiCrBSi Coatings on Ni- and Fe-Based Superalloys and Evaluation of Cyclic Oxidation Behaviour of Some Ni-Based Superalloys in Molten Salt Environment, Thin Solid Films, 2006, 515(1), p 95-105

H.S. Sidhu, B.S. Sidhu, and S. Prakash, Solid Particle Erosion of HVOF Sprayed NiCr and Stellite-6 Coatings, Surf. Coat. Technol., 2007, 202(2), p 232-238

J. Matějíček and Š. Houdková, Šimůnková, O. Bláhová, and Z. Pala, The Influence of Spraying Parameters on Stresses and Mechanical Properties of HVOF-Sprayed Co-Cr-W-C Coatings, Key Eng. Mater., 2014, 606, p 171-174

H.S. Sidhu, B.S. Sidhu, and S. Prakash, Performance of HVOF Sprayed NiCr and Stellite-6 Coatings under Pin on Disc Wear Testing, Mater. Sci. Forum, 2012, 701, p 21-29

J.F. Shackelford and W. Alexander, “CRC Materials Science and Engineering Handbook,” New York, 2001.

G. Straffelini, Friction and Wear: Methodologies for Design and Control, Springer International Publishing AG, Cham, 2015

Š. Houdková, E. Smazalová, M. Vostřák, and J. Schubert, Properties of NiCrBSi Coating, as Sprayed and Remelted by Different Technologies, Surf. Coat. Technol., 2014, 253, p 14-26

C.V. Cooper, C.L. Rollend, and D.H. Krouse, The Unlubricated Sliding Wear Behavior of a Wrought Cobalt-Chromium Alloy Against Monolithic Ceramic Counterfaces, J. Tribol., 1989, 111(4), p 668-674

A. Arizmendi-morquecho, A. Campa-castilla, J. Almicar, A. Martinez, G.V. Gutiérrez, K. Judith, M. Bello, and L.L. López, Microstructural Characterization and Wear Properties of Fe-Based Amorphous-Crystalline Coating Deposited by Twin Wire Arc Spraying, Adv. Mater. Sci. Eng., 2014, 2014, p 836739

A. Edrisy, T. Perry, and A.T. Alpas, Investigation of Scuffing Damage in Aluminum Engines with Thermal Spray Coatings, Wear, 2005, 259(7-12), p 1056-1062

C. Zhang, L. Liu, K.C. Chan, Q. Chen, and C.Y. Tang, Wear Behavior of HVOF-Sprayed Fe-Based Amorphous Coatings, Intermetallics, 2012, 29, p 80-85

G.W. Stachowiak and A.W. Batchelor, “Engineering Tribology,” Fourth Ed., (Burlington, MA, USA), Elsevier Butterworth-Heinemann, 2014.

A. Wank, A. Schwenk, B. Wielage, T. Grund, E. Friesen, and H. Pokhmurska, Untersuchungen Zur Beständigkeit Thermisch Gespritzter Schichten Im Vergleich Zu Hartchromschichten Bei Durch Abrasion Dominierter Tribologischer Beanspruchung, Materwiss. Werksttech., 2007, 38(2), p 144-148

Š. Houdková, F. Zahálka, M. Kašparová, and L.M. Berger, Comparative Study of Thermally Sprayed Coatings under Different Types of Wear Conditions for Hard Chromium Replacement, Tribol. Lett., 2011, 43(2), p 139-154

A. Ball, On the Importance of Work Hardening in the Design of Wear-Resistant Materials, Wear, 1983, 91(2), p 201-207

D.H.E. Persson, “On the Mechanisms behind the Tribological Performance of Stellites,” Uppsala University, 2005.

D. Chidambaram, C.R. Clayton, and M.R. Dorfman, Evaluation of the Electrochemical Behavior of HVOF-Sprayed Alloy Coatings, Surf. Coat. Technol., 2004, 192(3), p 278-283

G. Bolelli, L. Lusvarghi, and R. Giovanardi, A Comparison between the Corrosion Resistances of Some HVOF-Sprayed Metal Alloy Coatings, Surf. Coat. Technol., 2008, 202(19), p 4793-4809

Acknowledgments

The authors would like to thank Mr. Marsel Marku (Ecor Research SpA) for his assistance during the spraying experiments, and Dr. Paola Miselli and Dr. Miriam Hanusková (University of Modena and Reggio Emilia) for TG/DTA and particle size distribution measurements, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sassatelli, P., Bolelli, G., Lusvarghi, L. et al. Manufacturing and Properties of High-Velocity Oxygen Fuel (HVOF)-Sprayed FeVCrC Coatings. J Therm Spray Tech 25, 1302–1321 (2016). https://doi.org/10.1007/s11666-016-0451-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0451-3