Abstract

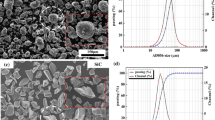

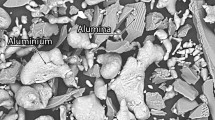

SiC-particle-reinforced Al5056-matrix composite coatings were deposited onto Al2024 substrates by cold spraying using a powder mixture having 15 vol.% SiC. To investigate the effects of friction stir processing (FSP) parameters on the microstructure and microhardness of the as-sprayed coating, the as-sprayed composite coating was then subjected to FSP using a stir tool having a threaded pin with rotation speed of 600 rpm and 1400 rpm. Results showed that the coatings presented Al and SiC phases before and after FSP treatment, and no other diffraction peaks were detected. Fine grains were produced in the Al5056 matrix due to severe plastic deformation during FSP, and the refined SiC particles exhibited a homogeneous distribution in the FSPed coating. In addition, an evident reduction of porosity (from 0.36% to 0.08% at 600 rpm or 0.09% at 1400 rpm) occurred, and a dramatic size reduction of the reinforcement from 12.5 µm to 6.5 µm at 600 rpm or 7.0 µm at 1400 rpm was achieved. Nevertheless, the microhardness profile presented general softening and a decrease from 143.9 HV to about 110 HV.

Similar content being viewed by others

References

A. Moridi, S.M. Hassani-Gangaraj, M. Guagliano, and M. Dao, Cold Spray Coating: Review of Material Systems and Future Perspectives, Surf. Eng., 2014, 30(6), p 369-395

W.Y. Li, C.J. Li, and H.L. Liao, Significant Influence of Particle Surface Oxidation on Deposition Efficiency, Interface Microstructure and Adhesive Strength of Cold-Sprayed Copper Coatings, Appl. Surf. Sci., 2010, 256(16), p 4953-4958

W.Y. Li, C. Zhang, X.P. Guo, G. Zhang, H.L. Liao, C.J. Li, and C. Coddet, Effect of Standoff Distance on Coating Deposition Characteristics in Cold Spraying, Mater. Des., 2008, 29(2), p 297-304

E. Irissou, J.G. Legoux, B. Arsenault, and C. Moreau, Investigation of Al–Al2O3 Cold Spray Coating Formation and Properties, J. Therm. Spray Technol., 2007, 16(5), p 661-668

M. Yu, W.Y. Li, X.K. Suo, and H.L. Liao, Effects of Gas Temperature and Ceramic Particle Content on Microstructure and Microhardness of Cold Sprayed SiCp/Al5056 Composite Coatings, Surf. Coat. Technol., 2013, 220, p 102-106

W.Y. Li, C. Yang, and H.L. Liao, Effect of Vacuum Heat Treatment on Microstructure and Microhardness of Cold-Sprayed TiN Particle-Reinforced Al Alloy-Based Composites, Mater. Des., 2011, 32(1), p 388-394

K.J. Hodder, H. Izadi, A.G. McDonald, and A.P. Gerlich, Fabrication of Aluminum–Alumina Metal Matrix Composites via Cold Gas Dynamic Spraying at Low Pressure Followed by Friction Stir Processing, Mat. Sci. Eng. A, 2012, 556, p 114-121

Q. Wang, K. Spencer, N. Birbilis, and M.X. Zhang, The Influence of Ceramic Particles on Bond Strength of Cold Spray Composite Coatings on AZ91 Alloy Substrate, Surf. Coat. Technol., 2010, 205(1), p 50-56

W.Y. Li, C. Zhang, H.L. Liao, J.L. Li, and C. Coddet, Characterizations of Cold-Sprayed Nickel–Alumina Composite Coating with Relatively Large Nickel-Coated Alumina Powder, Surf. Coat. Technol., 2008, 202(19), p 4855-4860

W.F. Xu, J.H. Liu, and D.L. Chen, Influence of Test Temperature on the Tensile Properties Along the Thickness in a Friction Stir Welded Aluminum Alloy, J. Mater. Sci. Technol., 2015, 31(9), p 953-961

D.R. Ni, J.J. Wang, and Z.Y. Ma, Shape Memory Effect, Thermal Expansion and Damping Property of Friction Stir Processed NiTip/Al Composite, J. Mater. Sci. Technol., 2016, 32(2), p 162-166

Z.Y. Ma, Friction Stir Processing Technology: A Review, Metall. Mater. Trans. A, 2008, 39(3), p 642-658

V. Sharma, U. Prakash, and B.V. Manoj Kumar, Surface Composites by Friction Stir Processing: A Review, J. Mater. Process. Technol., 2015, 224, p 117-134

Z.Y. Ma, R.S. Mishra, and M.W. Mahoney, Superplastic Deformation Behaviour of Friction Stir Processed 7075Al Alloy, Acta Mater., 2002, 50(17), p 4419-4430

A. Kurta, I. Uygurb, and E. Cete, Surface Modification of Aluminium by Friction Stir Processing, J. Mater. Process. Technol., 2011, 211(3), p 313-317

S. Pasebani, I. Charit, and R.S. Mishra, Effect of Tool Rotation Rate on Constituent Particles in a Friction Stir Processed 2024Al Alloy, Mater. Lett., 2015, 160, p 64-67

G.L. You, N.J. Ho, and P.W. Kao, Aluminum Based In Situ Nanocomposite Produced from Al–Mg–CuO Powder Mixture by Using Friction Stir Processing, Mater. Lett., 2013, 100, p 219-222

O.S. Salih, H. Ou, W. Sun, and D.G. McCartney, A Review of Friction Stir Welding of Aluminium Matrix Composites, Mater. Des., 2015, 86, p 61-71

Y. Morisada, H. Fujii, T. Mizuno, G. Abe, T. Nagaoka, and M. Fukusumi, Modification of Thermally Sprayed Cemented Carbide Layer by Friction Stir Processing, Surf. Coat. Technol., 2010, 204, p 2459-2464

H. Ashrafizadeh, A. Lopera-Valle, A. McDonald, and A. Gerlich, in Effect of Friction-Stir Processing on the Wear Rate of WC-Based MMC Coatings Deposited by Low-Pressure Cold Gas Dynamic Spraying, Thermal Spray 2015: Proceedings of the International Thermal Spray Conference (Long Beach, CA), 2015, p 41-47

C.J. Huang, W.J. Li, Z.H. Zhang, M.S. Fu, M.P. Planche, H.L. Liao, and G. Montavon, Modification of a Cold Sprayed SiCp/Al5056 Composite Coating by Friction Stir Processing, Surf. Coat. Technol., 2016, 296, p 69-75

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R Rep., 2005, 50(1–2), p 1-78

Z.H. Zhang, W.Y. Li, J.J. Shen, Y.J. Chao, J.L. Li, and Y.E. Ma, Effect of Backplate Diffusivity on Microstructure and Mechanical Properties of Friction Stir Welded Joints, Mater. Des., 2013, 50, p 551-557

J.D. Majumdar, B.R. Chandra, and I. Manna, Friction and Wear Behavior of Laser Composite Surfaced Aluminium with Silicon Carbide, Wear, 2007, 262, p 641-648

A. Shamsipur, S.F. Kashani-Bozorg, and A. Zarei-Hanzaki, The Effects of Friction-Stir Process Parameters on the Fabrication of Ti/SiC Nano-Composite Surface Layer, Surf. Coat. Technol., 2011, 206(6), p 1372-1381

W.Y. Li, C.J. Li, and H.L. Liao, Effect of Annealing Treatment on the Microstructure and Properties of Cold-Sprayed Cu Coating, J. Therm. Spray Technol., 2006, 15(2), p 206-211

O. Meydanoglu, B. Jodoin, and E.S. Kayali, Microstructure, Mechanical Properties and Corrosion Performance of 7075 Al Matrix Ceramic Particle Reinforced Composite Coatings produced by the Cold Gas Dynamic Spraying Process, Surf. Coat. Technol., 2013, 235, p 108-116

Y.S. Tao, T.Y. Xiong, C. Sun, L.Y. Kong, X.Y. Cui, T.F. Li, and G.L. Song, Microstructure and Corrosion Performance of a Cold Sprayed Aluminium Coating on AZ91D Magnesium Alloy, Corros. Sci., 2010, 52, p 3191-3197

K. Kang, G. Bae, J. Won, and C. Lee, Mechanical Property Enhancement of Kinetic Sprayed Al Coatings Reinforced by Multi-walled Carbon Nanotubes, Acta Mater., 2012, 60, p 5031-5039

P.S. Phani, V. Vishnukanthan, and G. Sundararajan, Effect of Heat Treatment on Properties of Cold Sprayed Nanocrystalline Copper Alumina Coatings, Acta Mater., 2007, 55(14), p 4741-4751

Acknowledgments

C.J. HUANG would like to thank the program of China Scholarship Council (201404490058) and Marie-Curie (268696) for financial support. W.Y. LI would also like to thank the National Natural Science Foundation of China (51574196) and 111 Project (B08040) for support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, C., Li, W., Zhang, Z. et al. Effect of Tool Rotation Speed on Microstructure and Microhardness of Friction-Stir-Processed Cold-Sprayed SiCp/Al5056 Composite Coating. J Therm Spray Tech 25, 1357–1364 (2016). https://doi.org/10.1007/s11666-016-0441-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0441-5