Abstract

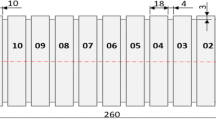

During machining of difficult-to-cut alloys, the rapid tool wear as a consequence of the high values of cutting forces and temperatures significantly affects the surface integrity of the machined surfaces reducing the product in-service performances. The use of conventional cutting fluids limits the tool deterioration, but provides several environmental issues to deal with, such as the exhausted fluid disposal, cleaning of the parts after machining, health hazards for the machines operators. In recent years, several researches have proposed to use environmental-friendly cryogenic coolants, whose very low operating temperatures have demonstrated to be able to inhibit the thermally activated tool wear mechanisms leaving the machined surface almost free from pollutants. In this framework, the aim of this research work is to analyze the surface integrity of the machined surfaces produced in semi-finishing turning of the Ti6Al4V titanium alloy under different low-temperature cooling techniques, namely liquid nitrogen (LN2), carbon dioxide (CO2) and gaseous nitrogen (N2) cooled at different temperatures, using the dry and wet cutting conditions as baseline. The surface integrity was evaluated considering both the surface finish (surface defects, roughness and topography) and the surface microstructural and mechanical alterations (altered layer, nano-hardness and residual stresses). The results showed that the best performances were obtained using N2 cooled at − 150 °C, which determined both the absence of surface defects, as wrinkles or feed marks irregularities typical of the surface generated under LN2, and high compressive residual stresses that made the surface suitable for biomedical and aerospace applications.

Similar content being viewed by others

References

E.O. Ezugwu and Z.M. Wang, Titanium Alloys and their Machinability a Review, J. Mater. Process. Technol., 1997, 68(3), p 262–274

M. Strano, E. Chiappini, S. Tirelli, P. Albertelli, and M. Monno, Comparison of Ti6Al4V Machining Forces and Tool Life for Cryogenic Versus Conventional Cooling, J. Eng. Manuf., 2013, 227(9), p 1403–1408

M.J. Bermingham, J. Kirsch, S. Sun, S. Palanisamy, and M.S. Dargusch, New Observations on Tool Life, Cutting Forces and Chip Morphology in Cryogenic Machining Ti-6Al-4V, Int. J. Mach. Tools Manuf, 2011, 51(6), p 500–511

B.D. Jerold and M.P. Kumar, Experimental Comparison of Carbon-dioxide and Liquid Nitrogen Cryogenic Coolants in Turning of AISI, 1045 Steel, Cryogenics, 2012, 52(10), p 569–574

S.M. Yuan, L.T. Yan, W.D. Liu, and Q. Liu, Effects of Cooling Air Temperature on Cryogenic Machining of Ti-6Al-4V Alloy, J. Mater. Process. Tech., 2011, 211(3), p 356–362

S. Sun, M. Brandt, S. Palanisamy, and M.S. Dargusch, Effect of Cryogenic Compressed Air on the Evolution of Cutting Force and Tool Wear During Machining of Ti-6Al-4V Alloy, J. Mater. Process. Tech., 2015, 221, p 243–254

R. Bertolini, S. Bruschi, A. Ghiotti, L. Pezzato, and M. Dabalà, Influence of the Machining Cooling Strategies on the Dental Tribocorrosion Behaviour of Wrought and Additive Manufactured Ti6Al4V, Biotribology, 2017, 11, p 1

S. Bruschi, R. Bertolini, A. Bordin, F. Medea, and A. Ghiotti, Influence of the Machining Parameters and Cooling Strategies on the Wear Behavior of Wrought and Additive Manufactured Ti6Al4V for Biomedical Applications, Tribiol. Int., 2016, 102, p 133–142

P. Dahlman, F. Gunnberg, and M. Jacobson, The Influence of Rake Angle, Cutting Feed and Cutting Depth on Residual Stresses in Hard Turning, J. Mater. Process. Technol., 2004, 147, p 181–184

E. Capello, Residual Stresses in Turning Part I: Influence of Process Parameters, J. Mater. Process. Tech., 2005, 160, p 221–228

F. Pusavec, H. Hamdi, J. Kopac, and I.S. Jawahir, Surface Integrity in Cryogenic Machining of Nickel Based Alloy—Inconel 718, J. Mater. Process. Technol., 2011, 211(4), p 773–783

G. Rotella, O.W. Dillon, D. Umbrello, and L. Settineri, The Effects of Cooling Conditions on Surface Integrity in Machining of Ti6Al4V Alloy, Int. J. Adv. Manuf. Technol., 2014, 71, p 47–55

Y. Sun, B. Huang, D.A. Puleo, J. Schoop, and I.S. Jawahir, Improved Surface Integrity from Cryogenic Machining of Ti-6Al-7Nb Alloy for Biomedical Applications, Proc. CIRP, 2016, 45, p 63–66

A. Ginting and M. Nouari, Surface Integrity of Dry Machined Titanium Alloys, Int. J. Mach. Tools Manuf., 2009, 49(3–4), p 325–332

J.M. Zhou, V. Bushlya, and J.E. Stahl, An Investigation of Surface Damage in the High Speed Turning of Inconel 718 with Use of Whisker Reinforced Ceramic Tools, J. Mater. Process. Tech., 2012, 212(2), p 372–384

S. Sartori, A. Bordin, A. Ghiotti, and S. Bruschi, Analysis of the Surface Integrity in Cryogenic Turning of Ti6Al4V Produced by Direct Melting Laser Sintering, Proc. CIRP, 2016, 45, p 123–126

A. Bordin et al., Feasibility of Cryogenic Cooling in Finishing Turning of Acetabular Cups Made of Additive Manufactured Ti6Al4V, Proc. CIRP, 2016, 46, p 615–618

S. Sartori, A. Ghiotti, and S. Bruschi, Temperature Effects on the Ti6Al4V Machinability Using Cooled Gaseous Nitrogen in Semi-finishing Turning, J. Manuf. Process., 2017, 30, p 187–194

ASTM-F1472, Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical Implant Applications (UNS R56400) 1. (2014)

Sandvik Bioline, Sandvik Bioline Ti6Al4V ELI datasheet

M.A. Gepreel and M. Niinomi, Biocompatibility of Ti-Alloys for Long-Term Implantation, J. Mech. Behav. Biomed. Mater., 2013, 20, p 407–415

A. Bordin, S. Bruschi, A. Ghiotti, and P.F. Bariani, Analysis of Tool Wear in Cryogenic Machining of Additive Manufactured Ti6Al4V Alloy, Wear, 2015, 328–329, p 89–99

ISO4287:1197, Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters

ASTME407-70, Standard Test Method for Microetching Metals and Alloys. (1989)

Struers, Metallographic Preparation of Titanium Application Notes. (2015)

Y. Murakami and M. Itokazu, Elastic-Plastic Analysis of a Triangular Pyramidal Identation, Int. J. Solids Sruct., 1997, 34(30), p 4005–4018

B. Jung, H. Lee, and H. Park, Effect of Grain Size on the Indentation Hardness for Polycrystalline Materials by the Modified Strain Gradient Theory, Int. J. Solids Struct., 2013, 50, p 2719–2724

M. Dhananchezian and M.P. Kumar, Cryogenic Turning of the Ti-6Al-4V Alloy with Modified Cutting Tool Inserts, Cryogenics (Guildf), 2011, 51(1), p 34–40

J.D.P. Velásquez, A. Tidu, B. Bolle, P. Chevrier, and J. Fundenberger, Sub-surface and Surface Analysis of High Speed Machined Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2010, 527, p 2572–2578

A.F. Gerday, M. Ben Bettaieb, L. Duchêne, N. Clement, H. Diarra, and A.M. Habraken, Material Behavior of the Hexagonal Alpha Phase of a Titanium Alloy Identified from Nanoindentation Tests, Eur. J. Mech./A Solids, 2011, 30(3), p 248–255

M. Cornen, P. Castany, I. Péron, and T. Gloriant, Materials Science and Engineering A Determination of Hardness and Elastic Modulus Inverse Pole Figures of a Polycrystalline Commercially Pure Titanium by Coupling Nanoindentation and EBSD Techniques, Mater. Sci. Eng. A, 2014, 613, p 159–162

F.K. Mante, G.R. Baran, and B. Lucas, Nanoindentation studies of titanium single crystals, Biomaterials., 1999, 20, p 1051–1055

A.W. Warren and Y.B. Guo, Machined surface properties determined by nanoindentation: Experimental and FEA studies on the effects of surface integrity and tip geometry, Chem. Mater. Sci., 2006, 201, p 423–433

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sartori, S., Pezzato, L., Dabalà, M. et al. Surface Integrity Analysis of Ti6Al4V After Semi-finishing Turning Under Different Low-Temperature Cooling Strategies. J. of Materi Eng and Perform 27, 4810–4818 (2018). https://doi.org/10.1007/s11665-018-3598-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3598-x