Abstract

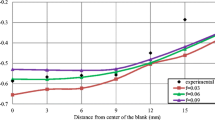

The present work aims to investigate the effects of the temperature gradient developed within the tool profiles on the formability of IS 513 CR3-grade steel sheets using the cup drawing test. The deformation characteristics of steel sheets were analyzed by comparing the thicknesses in various regions of the formed cup and also the limiting drawing ratios (LDR). Finite element simulations were carried out to predict the behavior of the steel sheets in isothermal and non-isothermal forming using Abaqus/Standard 6.12-1. An analytical model created by Kim was used to validate the experimental and finite element analysis (FEA) results on identical process parameters. Both the FEA and analytical modeling results showed that formability improvement is possible in warm forming; the findings are in good agreement with the experimental results in determining the locations and values of excessive thinning. The results also indicated that formability improvement cannot be achieved by keeping the tooling temperature at the same level. The LDR increased by around 9.5% in isothermal forming and by 19% in non-isothermal forming (with the punch maintained at a lower temperature compared with the die and blank holder). In addition, the fractured surfaces of unsuccessfully formed samples were analyzed using scanning electron microscopy. Metallographic investigations confirmed that the fracture mechanism during the forming of IS 513 CR3-grade steel sheets depends on the brittleness, strain hardening value, forming temperature, and magnitude of stresses developed.

Similar content being viewed by others

Abbreviations

- F :

-

Drawing force

- F p :

-

Drawing load

- K :

-

Strain hardening coefficient

- n :

-

Strain hardening exponent

- ε 0 :

-

Material constant

- \(\bar{\sigma }\) :

-

Equivalent plastic stress

- Fc:

-

Critical punch force

- \(t_{\text{e}} t_{\text{b }}\) :

-

Thickness of the blank element before and after bending

- \(t_{0}\) :

-

Initial and current thickness of the blank

- \(\bar{\varepsilon }\) :

-

Equivalent plastic strain rate

- \(\rho_{\text{c}} \;\rho_{\text{n}}\) :

-

Radii of the central and neutral axes

- λ b :

-

Displacement of the neutral axis from the central axis

- \(\sigma_{\text{f}} \sigma_{\text{ub}}\) :

-

Drawing stress before and after bending

References

R.J. Fekete, Overview of Sheet Metals for Stamping, Soc. Autom. Eng., 1997, 106, p 699–710

H.J. Bong, F. Barlat, D.C. Ahn, H.Y. Kim, and M.G. Lee, Formability of Austenitic and Ferritic Stainless Steels at Warm Forming Temperature, Int. J. Mech. Sci., 2013, 75, p 94–109

M. Zaeimi, A. Basti, and M. Alitavoli, Effect of Martensite Volume Fraction on Forming Limit Diagrams of Dual-Phase Steel, J. Mater. Eng. Perform., 2015, 24(5), p 1781–1789

S.K. Singh, K. Mahesh, A. Kumar, and M. Swathi, Understanding Formability of Extra Deep Drawing Steel at Elevated Temperature Using Finite Element Simulation, Mater. Des., 2010, 31(9), p 4478–4484

B. Sarkar, B.K. Jha, and A. Deva, Optimization of Annealing Parameters for Improvement in Formability of Extra Deep Drawing Quality Steel, J. Mater. Eng. Perform., 2004, 13(3), p 361–365

S.K. Singh, A.K. Gupta, and K. Mahesh, A Study on the Extent of Ironing of EDD Steel at Elevated Temperature, CIRP J. Manuf. Sci. Technol., 2010, 3(1), p 73–79

A.H. Van Den Boogaard, P.J. Bolt, and R.J. Werkhoven, Modeling of AlMg Sheet Forming at Elevated Temperatures, Int. J Form. Process, 2001, 4, p 361–375

P.J. Bolt, N.A.P.M. Lamboo, and P.J.C.M. Rozier, Feasibility of Warm Drawing of Al Products, J. Mater. process Technol., 2001, 115, p 118–121

F. Shehata, M.J. Painter, and R. Pearce, Warm Forming of Aluminum/Magnesium Alloy Sheet, J. Mech. Work Technol., 1978, 2, p 279–290

T. Mayavan and L. Karthikeyan, Influence of Process Parameters on Limiting Drawing Ratio of IS513 CR3 Grade Steel Sheet During Warm Deep Drawing, Adv. Mater. Res., 2014, 984–985, p 62–66

H.S. Kim, M. Koç, and J. Ni, Development of an Analytical Model for Warm Deep Drawing of Aluminum Alloys, J. Mater. Process. Technol., 2008, 197(1–3), p 393–407

T. Naka, R. Hino, and F. Yoshida, Deep Drawability of 5083 Al-Mg Alloy Sheet at Elevated Temperature and Its Prediction, Key Eng. Mater., 2000, 177–180, p 485–490

S. Bagherzadeh, M.J. Mirnia, and B.M. Dariani, Numerical and Experimental Investigations of Hydro-mechanical Deep Drawing Process of Laminated Aluminum/Steel Sheets, J. Manuf. Processes, 2015, 18, p 131–140

H. Takuda, K. Mori, I. Masuda, Y. Abe, and M. Matsuo, Finite Element Simulation of Warm Deep Drawing of Aluminum Alloy Sheet When Accounting for Heat Conduction, J. Mater. Process Technol., 2002, 120, p 412–418

H. Palaniswamy, G. Nagile, and T. Altan, Finite Element Simulation of Magnesium Alloy Sheet Forming at Elevated Temperatures, J. Mater. Process Technol., 2004, 146, p 52–60

http://www.thefabricator.com/article/metalsmaterials/warm-forming-of-stainless-steels—part-ii

S.M. Hussaini, S.K. Singh, and A.K. Gupta, Formability and Fracture Studies of Austenitic Stainless Steel 316 at Different Temperatures, J. King Saud. Univ. Eng. Sci., 2014, 26(2), p 184–190

M.D. Toit and H.G. Steyn, Comparing the Formability of AISI, 304 and AISI, 202 Stainless Steels, J. Mater. Eng. Perform., 2012, 21(7), p 1491–1495

R. Ramadoss and A. Rajadurai, Forming Limit Analysis of AISI, 316LN-Austenitic Stainless Steel, Int. J. Microstruct. Mater. Prop., 2009, 4(4), p 436–454

S.K. Singh and D. Ravi Kumar, Effect of process parameters on product surface finish and thickness variation in hydro mechanical deep drawing, J. Mater. Process. Technol., 2008, 204(1–3), p 169–178

D.G. Tari, M.J. Worswick, and S. Winkler, Experimental Studies of Deep Drawing of AZ31B Magnesium Alloy Sheet Under Various Thermal Conditions, J. Mater. Process. Technol., 2013, 213(8), p 1337–1347

N. Kotkunde, A.D. Deole, A.K. Gupta, and S.K. Singh, Experimental and numerical investigation of anisotropic yield criteria for warm deep drawing of Ti-6Al-4V alloy, Mater. Des., 2014, 63, p 336–344

H. Zhang, G. Huang, J. Fan, H.J. Roven, F. Pan, and B. Xu, Deep drawability and Deformation Behavior of AZ31 Magnesium Alloy Sheets at 473K, Mater. Sci. Eng. A, 2014, 608, p 234–241

G. Erdem and Y. Taptik, Effect of hot rolling conditions to produce deep drawing quality steels for continuous annealing process, J. Mater. Process. Technol., 2005, 170(1–2), p 17–23

M. Torkar, F. Tehovnik, and B. Podgornik, Failure analysis of deep drawing of low carbon steel sheets, Eng. Fail. Anal., 2014, 40, p 1–7

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mayavan, T., Karthikeyan, L. & Senthilkumar, V.S. Experimental and Numerical Studies on Isothermal and Non-isothermal Deep Drawing of IS 513 CR3 Steel Sheets. J. of Materi Eng and Perform 25, 4837–4847 (2016). https://doi.org/10.1007/s11665-016-2325-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2325-8