Abstract

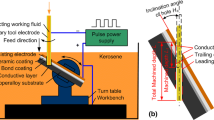

Thermal barrier coatings (TBCs) are used to thermally insulate superalloy components from the hot gas streams in gas turbine engines. In this work, electrical discharge machining (EDM) was used to machine different inclined holes in TBC-coated nickel superalloys by integrating the inner-jet-liquid rotating electrode method and the assisting electrode method. The influences of the inclination angle (i.e., from 0° to 60°) and EDM parameters (i.e., peak current, pulse duration, duty factor and flushing pressure) on the machining time and electrode wear were investigated. The surface morphologies and elemental distribution were analyzed using a scanning electron microscope and an energy dispersive spectroscope. The results of the analysis showed that the 8YSZ ceramic coating is more prone to brittle fracture and cracking than the IN718 substrate and NiCoAlY bond coating, and pits and cracks become more pronounced as the inclination angle increases. The damage on the trailing edge is primarily caused by the thermal stress fracture, and the damage on the leading edge is mainly caused by thermal erosion. Using high-energy parameters, a delamination with dimensions of 28 μm (W) × 200 μm (L) occurs on the trailing edges of the coating/substrate interface.

Similar content being viewed by others

References

M. Azadi, G.H. Farrahi, and A. Moridi, Optimization of air plasma sprayed thermal barrier coating parameters in diesel engine applications, J. Mater. Eng. Perform., 2013, 22(11), p 3530–3538

N.P. Padture, M. Gell, and E.H. Jordan, Thermal barrier coatings for gas-turbine engine applications, Science, 2002, 296(5566), p 280–284

A. Corcoran, L. Sexton, B. Seaman, P. Ryan, and G. Byrne, The laser drilling of multi-layer aerospace material systems, J. Mater. Process. Technol., 2002, 123(1), p 100–106

J. Kamalu, P. Byrd, and A. Pitman, Variable angle laser drilling of thermal barrier coated nimonic, J. Mater. Process. Technol., 2002, 122(2–3), p 355–362

H.K. Sezer, L. Li, M. Schmidt, A.J. Pinkerton, B. Anderson, and P. Williams, Effect of beam angle on HAZ, recast and oxide layer characteristics in laser drilling of TBC nickel superalloys, Int. J. Mach. Tools Manuf., 2006, 46(15), p 1972–1982

S. Marimuthu, A.M. Kamara, H.K. Sezer, L. Li, and G.K.L. Ng, Numerical investigation on laser stripping of thermal barrier coating, Comput. Mater. Sci., 2014, 88, p 131–138

Q. Feng, Y.N. Picard, J.P. McDonald, P.A. Van Rompay, S.M. Yalisove, and T.M. Pollock, Femtosecond laser machining of single-crystal superalloys through thermal barrier coatings, Mater. Sci. Eng. A, 2006, 430(1–2), p 203–207

D.K. Das, J.P. McDonald, S.M. Yalisove, and T.M. Pollock, Femtosecond pulsed laser damage characteristics of 7% Y2O3–ZrO2 thermal barrier coating, Appl. Phys. A, 2008, 91(3), p 421–428

D.K. Das and T.M. Pollock, Femtosecond laser machining of cooling holes in thermal barrier coated CMSX4 superalloy, J. Mater. Process. Technol., 2009, 209(15), p 5661–5668

D.K. Das, J.P. McDonald, S.M. Yalisove, and T.M. Pollock, Depth-profiling study of a thermal barrier coated superalloy using femtosecond laser-induced breakdown spectroscopy, Spectrochim. Acta B At. Spectrosc., 2008, 63(1), p 27–36

O. Yilmaz, A.T. Bozdana, and M.A. Okka, An intelligent and automated system for electrical discharge drilling of aerospace alloys: Inconel 718 and Ti-6Al-4V, Int. J. Adv. Manuf. Technol., 2014, 74(9–12), p 1323–1336

L. Li, X.T. Wei, Y.B. Guo, W. Li, and J.F. Liu, Surface integrity of Inconel 718 by Wire-edm at different energy modes, J. Mater. Eng. Perform., 2014, 23(8), p 3051–3057

P. Sharma, S. Singh, and D.R. Mishra, Electrical discharge machining of AISI, 329 stainless steel using copper and brass rotary tubular electrode, Procedia Mater. Sci., 2014, 5, p 1771–1780

P. Kuppan, A. Rajadurai, and S. Narayanan, Influence of EDM process parameters in deep hole drilling of Inconel 718, Int. J. Adv. Manuf. Technol., 2008, 38(1–2), p 74–84

N. Mohri, Y. Fukuzawa, T. Tani, N. Saito, and K. Furutani, Assisting electrode method for machining insulating ceramics, CIRP Ann. Manuf. Technol., 1996, 45(1), p 201–204

P. Hou, Y. Guo, D. Shao, Z. Li, Y. Wureli, and L. Tang, Influence of open-circuit voltage on high-speed wire electrical discharge machining of insulating zirconia, Int. J. Adv. Manuf. Technol., 2014, 73(1–4), p 229–239

T. Hösel, C. Müller, and H. Reinecke, Spark erosive structuring of electrically nonconductive zirconia with an assisting electrode, CIRP J. Manuf. Sci. Technol., 2011, 4(4), p 357–361

R. Ji, Y. Liu, Y. Zhang, F. Wang, B. Cai, and X. Fu, Single discharge machining insulating Al2O3 ceramic with high instantaneous pulse energy in kerosene, Mater. Manuf. Process., 2012, 27(6), p 676–682

R. Ji, Y. Liu, Y. Zhang, H. Zhang, X. Li, and X. Dong, An experimental research on single discharge machining of insulating ceramics efficiently with high energy capacitor, Sci. China Technol. Sci., 2011, 54(6), p 1537–1545

R. Ji, Y. Liu, R. Diao, C. Xu, X. Li, B. Cai, Y. Zhang, Influence of electrical resistivity and machining parameters on electrical discharge machining performance of engineering ceramics. PLoS One 2014, 9(11), p e110775

A. Schubert, H. Zeidler, M. Hahn, M. Hackert-Oschätzchen, and J. Schneider, Micro-EDM milling of electrically nonconducting zirconia ceramics, Procedia CIRP, 2013, 6(6), p 297–302

G. Kucukturk and C. Cogun, A new method for machining of electrically nonconductive workpieces using electric discharge machining technique, Mach. Sci. Technol., 2010, 14(2), p 189–207

Y. Guo, G. Zhang, L. Wang, and Y. Hu, Optimization of parameters for EDM drilling of thermal-barrier-coated nickel superalloys using gray relational analysis method, Int. J. Adv. Manuf. Technol., 2016, 83(9–12), p 1595–1605

N. Mohri, Y. Fukuzawa, T. Tani, and T. Sata, Some considerations to machining characteristics of insulating ceramics-towards practical use in industry, CIRP Ann. Manuf. Technol., 2002, 51(1), p 161–164

W. Zhu, L. Yang, J.W. Guo, Y.C. Zhou, and C. Lu, Numerical study on interaction of surface cracking and interfacial delamination in thermal barrier coatings under tension, Appl. Surf. Sci., 2014, 315, p 292–298

P. Seiler, M. Bäker, and J. Rösler, Multi-scale failure mechanisms of thermal barrier coating systems, Comput. Mater. Sci., 2013, 80, p 27–34

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, G., Guo, Y. & Wang, L. Experimental Study on the Machining of Inclined Holes for Thermal Barrier-Coated Nickel Superalloys by EDM. J. of Materi Eng and Perform 25, 4574–4580 (2016). https://doi.org/10.1007/s11665-016-2287-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2287-x