Abstract

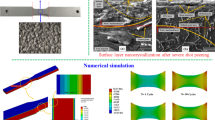

The shot peening is used in the leaf springs manufacturing process for producing a compressive residual stress field (CRSF) at and near the surface that improves the fatigue resistance. The resulting CRSF is influenced by the surface ferrite thickness associated with the decarburization. Hence, this work aims to extend the knowledge on the influence of the decarburization on the CRSF for the given shot peening conditions. A study on the laboratory scale was conducted for an SAE 5160 steel grade used in the automotive industry. Next, specimens with different decarburization depths were treated using industrial shot peening, and the resulting CRSF was characterized. The CRSF was found to be influenced by the decarburization depth. It is assumed that the elastic deformation mechanism is predominant at low decarburization depths, followed by a zone in which both the elastic and plastic deformation have competing mechanisms that contribute to the CRSF, and at higher decarburization depths, the dominant mechanism is plastic deformation. The values for σsrs and σmcrs decrease as the decarburized depth increases, and suitable CRSFs were obtained below a decarburization depth of 120 µm in industrial leaves. Furthermore, the prediction based on expressions correlating the measured variables was good in these leaves.

Similar content being viewed by others

References

B. Geoffroy and N. Batista, Role of Residual Stresses Induced by Double Peening on Fatigue Durability of Automotive Leaf Springs, Mater. Des., 2013, 47, p 672

J. Toribio, Residual Stress Effects in Stress-Corrosion Cracking, J. Mater. Eng. Perform., 1998, 7(2), p 173–182

S. Andreza and S. Valdemir, Analytical Modelling for Residual Stresses Produced by Shot Peening, Mater. Des., 2009, 30, p 1556

S. Tekeli, Enhancement of Fatigue Strength of SAE 9245 Steel by Shot Peening, Mater. Lett., 2002, 57, p 604

Y. Gao and M. Yao, An analysis of Residual Stress Fields Caused by Shot Peening, Metall. Mater. Trans. A, 2002, 33A, p 1775

M. Kobayashi and T. Matsui, Mechanism of Creation of Compressive Residual Stress by Shot Peening, Int. J. Fatigue, 1998, 20(5), p 351

H. Wohlfahrt, The influence of peening conditions on the resulting distribution of residual stress ICSP-2, 1984, p 316.

D. Burzic and J. Zamberjer, Non-destructive Evolution of Decarburization of Spring Steel Using Electromagnetic Measurement, NDT&E Int., 2010, 43, p 446

R.G. Baggerly and R.A. Drollinger, Determination of Decarburization in Steel, J. Mater. Eng. Perform., 1993, 2(1), p 47

M.J. Gildersleeve, Relationship Between Decarburization and Fatigue Strength of Through Hardened and Carburizing Steels, Mater. Sci. Technol., 1991, 7, p 307

Y. Prawoto, N. Sato, I. Otani, and M. Ikeda, Carbon Restoration for Decarburized Layer in Spring Steel, J. Mater. Eng. Perform., 2004, 13(5), p 627

T. Hong and J. Ooi, A numerical Simulation to Relate the Shot Peening Parameters to the Induced Residual Stresses, Eng. Fail. Anal., 2008, 15, p 1097

D. Li and D. Anghelina, Investigation of Decarburization in Spring Steel Production Process—Part I: Experiments, Steel Res., 2009, 80(4), p 298

S.J. Jones and H. Bhadeshia, Kinetics of the Simultaneous Decomposition of Austenite into Several Transformation Products, Acta Mater., 1997, 45(7), p 2911–2920

D. Li and D. Anghelina, Investigation of Decarburization in Spring Steel Production Process—Part II: Simulation, Steel Res., 2009, 80(4), p 304

K. Dalaei and J. Höijer, Influence of decarburization on the fatigue behavior of shot peening spring steels, The 10th International Conference on Shot Peening, Tokio, 2008.

Acknowledgment

This work has been financially supported by the National Council of Science and Technology (CONACYT, México). The authors also acknowledge RASSINI suspensions SA of CV (Piedras Negras, Coah. México) for the material and information given.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

De la Rosa, C.E.F., Trejo, M.H., Román, M.C. et al. Effect of Decarburization on the Residual Stresses Produced by Shot Peening in Automotive Leaf Springs. J. of Materi Eng and Perform 25, 2596–2603 (2016). https://doi.org/10.1007/s11665-016-2132-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2132-2