Abstract

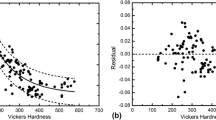

This paper presents a method for predicting the strain-based forming limit curve (FLC) for steels using hardness. The stretching side (positive minor strain component) of the FLC was calculated by using a Marciniak-Kuczyński model with a non-quadratic yield function, while the drawing side (negative minor strain component) of the FLC was predicted based on the relationship between the major and minor critical strains, in accordance with the theory of maximum sheet tension for local necking. The requisite parameter that describes the plastic flow behavior (in this case, the strain hardening exponent) was calculated, based on correlations with the measured microhardness. Additionally, the strain rate sensitivity was considered in the model by using a newly developed empirical correlation between hardness and strain rate sensitivity. This hardness-based model was used to predict FLCs that demonstrate good agreement with experimental FLCs of a high-strength low-alloy steel and a dual-phase steel. Equations are provided that enable the calculation of the FLC from given hardness values for different severities of the material inhomogeneity.

Similar content being viewed by others

References

S.P. Keeler and W.A. Backhofen, Plastic Instability and Fracture in Sheet Stretched over Rigid Punches, ASM Trans. Q., 1964, 56, p 25–48

G.M. Goodwin, Application of Strain Analysis to Sheet Metal Forming in the Press Shop, SAE Paper 680093, 1968

Z. Marciniak and J.L. Duncan, The Mechanics of Sheet Metal Forming, Edward Arnold, London, 1992

S.P. Keeler and W.G. Brazier, Relationship Between Laboratory Material Characterization and Press Shop Formability, Microalloying 75 Proceedings, Washington, DC, 1977, p 517–528.

M.F. Shi, Strain hardening and forming limits of automotive steels. SAE Paper Number 950700, 1995.

A. Konieczny, On Formability Assessment of the Automotive Dual Phase Steels, SAE2001-01-3075, Proceedings of SAE 2001 World Congress, SAE, Warrendale, 2001

F. Cayssails, A New Method for Predicting FLC, Proceeding of the 20th Biennial Congress of the IDDRG, Genval, 1998, p 443–454.

F. Cayssails and X. LeMoine, Predictive Model of FLC (Arcelor model) Upgraded to UHSS Steels, Proceedings of the 2005 IDDRG Conference, Besançon, 2005

K.S. Raghavan, R.C. Van Kuren, and H. Darlington, Recent Progress in the Development of Forming Limit Curves for Automotive Sheet Steel. SAE Paper Number 920437, 1992

M. Abspoel, M.E. Scholting, J.M.M. Droog, and N.J. Langarak, Predicting Forming Limit Curves from Mechanical Properties, Proceeding of 2013 IDDRG Conference, Mumbai, 2013, p 48–59.

J.R. Cahoon, W.H. Broughton, and A.R. Kutzak, The Determination of Yield Strength from Hardness Measurements, Metall. Trans., 1971, 2, p 1979–1983

J.R. Cahoon, An Improved Equation Relating Hardness to Ultimate Strength, Metall. Trans., 1972, 3, p 3040

E.J. Pavlina and C.J. Van Tyne, Uniform Elongation and the Stress-Strain Flow Curve of Steels Calculated from Hardness Using Empirical Correlations, J. Mater. Eng. Perform., 2014, 23, p 2247–2253

D. Tabor, The Hardness and Strength of Metals, J. Inst. Met., 1951, 79, p 1–18

X.-L. Gao, X.N. Jing, and G. Subhash, Two New Expanding Cavity Models for Indentation Deformations of Elastic Strain-hardening Materials, Int. J. Solids Struct., 2006, 43, p 2193–2208

N.A. Branch, G. Subhash, N.K. Arakere, and M.A. Klecka, A New Reverse Analysis to Determine the Constitutive Response of Plastically Graded Case Hardened Bearing Steels, Int. J. Solids Struct., 2011, 48, p 584–591

E.J. Pavlina and C.J. Van Tyne, Correlation of Yield Strength and Tensile Strength with Hardness for Steels, J. Mater. Eng. Perform., 2008, 17, p 888–893

Z. Marciniak and K. Kuczyński, Limit Strains in the Processes of Stretch-forming Sheet Metal, Int. J. Mech. Sci., 1967, 9, p 609–620

A. Graf and W. Hosford, Calculations of Forming Limit Diagrams, Metall. Trans. A, 1990, 21, p 87–94

A. Ghazanfari and A. Assempour, Calibration of Forming Limit Diagrams Using a Modified Marciniak-Kuczynski Model and an Empirical Law, Mater. Des., 2012, 34, p 185–191

L.C. Chan and X.Z. Lu, Material Sensitivity and Formability Prediction of Warm-forming Magnesium Alloy Sheets with Experimental Verification, Int. J. Adv. Manuf. Technol., 2014, 71, p 253–262

T.J. McCarron, K.E. Kain, G.T. Hahn, and W.F. Flanagan, Effect of Geometrical Defects in Forming Sheet Steels by Biaxial Stretching, Metall. Trans. A, 1988, 19, p 2067–2074

R. Logan and W.F. Hosford, Upper-bound Anisotropic Yield Locus Calculations Assuming<111>-pencil Glide, Int. J. Mech. Sci., 1980, 22, p 419–430

A.K. Ghosh, The Effect of Lateral Drawing-in on Stretch Formability, Met. Eng. Q., 1979, 15, p 53–64

F. Barlat, Crystallographic Texture, Anisotropic Yield Surfaces and Forming Limits of Sheet Metals, Mater. Sci. Eng., 1987, 91, p 55–72

P. Larour, “Strain Rate Sensitivity of Automotive Sheet Steels: Influence of Plastic Strain, Strain Rate, Temperature, Microstructure, Bake Hardening and Pre-strain,” PhD dissertation, RWTH Aachen University, 2010

B.S. Levy, A Comparison of Empirical Forming Limit Curves for Low Carbon Steel with Theoretical Forming Limit Curves of Ramaekers and Bongaerts, IDDRG WG3, Ungarn, June 13–14, 1996

S.S. Hecker, A Simple Forming Limit Curve Technique and Results on Aluminum Alloys, IDDRG 7th Biennial Congress, 1972, p 5.1–5.26

W. Bleck, Z. Deng, K. Papamantellos, and C.O. Gusek, A Comparative Study of the Forming-limit Diagram Models for Sheet Steels, J. Mater. Proc. Technol., 1998, 83, p 223–230

J.H. Percy, The Effect of Strain Rate on the Forming Limit Diagram for Sheet Metal, CIRP Ann., 1980, 29, p 151–152

A.M. Brown, A Step-by-step Guide to Non-linear Regression Analysis of Experimental Data Using a Microsoft Excel Spreadsheet, Comput. Methods Progr. Biomed., 2001, 65, p 191–200

B.S. Levy and D.E. Green, Enhanced Forming Limit Diagram—Project Team Research Report, Auto/Steel Partnership, Southfield, MI, 2002

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pavlina, E.J., Van Tyne, C.J. Prediction of Forming Limit Curves from Hardness for Steels. J. of Materi Eng and Perform 25, 3465–3471 (2016). https://doi.org/10.1007/s11665-016-2115-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2115-3