Abstract

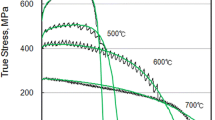

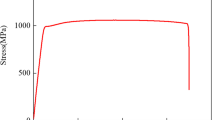

Hot tensile behavior of TA15 sheets with bimodal microstructure was studied through tensile tests from 750 to 850 °C with an interval of 25 °C and at strain rates of 0.001, 0.01, and 0.1 s−1. Results of the tensile tests reveal that the flow stress reaches peak values at specific strains, and then softening or steady-state flow occurs. Metallographic examination of deformed specimens shows that the primary α-phase becomes equiaxed, while the secondary α-phase and the lamellar β-phase are curved until crushed, indicating that the deformation occurred mainly in the secondary α-phase and the lamellar β-phase. A self-consistent model was developed to predict the plastic flow behavior of the TA15 sheets. Model parameters were determined according to the composition contents of individual phases and the stress-strain curves. The stress-strain curves at 775 °C and at the strain rates of 0.001, 0.01, and 0.1 s−1 were predicted by the proposed model, showing good agreement with the experimental results.

Similar content being viewed by others

References

G.S. Srinivasu and N.R. Raja, Finite Element Modeling of Stress Strain Curve and Micro Stress and Micro Strain Distributions of Titanium Alloys—A Review, J. Miner. Mater. Charact. Eng., 2012, 11, p 953–960

S. Tamirisakandala, B.V. Vedam, and R.B. Bhat, Recent Advances in the Deformation Processing of Titanium Alloys, J. Mater. Eng. Perform., 2003, 12, p 661–673

A.N. Chamos, G.N. Labeas, and D. Setsika, Tensile Behavior and Formability Evaluation of Titanium-40 Material Based on the Forming Limit Diagram Approach, J. Mater. Eng. Perform., 2013, 22, p 2253–2260

D. He, J. Zhu, S. Zaefferer, and D. Raabe, Effect of Retained Beta Layer on Slip Transmission in Ti-6Al-2Zr-1Mo-1V Near Alpha Titanium Alloy During Tensile Deformation at Room Temperature, Mater. Des., 2014, 56, p 937–942

X.G. Fan, H. Yang, and P.F. Gao, Deformation Behavior and Microstructure Evolution in Multistage Hot Working of TA15 Titanium Alloy: On the Role of Recrystallization, J. Mater. Sci., 2011, 46(18), p 6018–6028

P. Vo, M. Jahazi, S. Yue, and P. Bocher, Flow Stress Prediction During Hot Working of Near Alpha Titanium Alloys, Mater. Sci. Eng. A, 2007, 447(1-2), p 99–110

X.G. Fan and H. Yang, Internal-State-Variable Based Self-consistent Constitutive Modeling for Hot Working of Two-Phase Titanium Alloys Coupling Microstructure Evolution, Int. J. Plast., 2011, 27(11), p 1833–1852

J. Xiao, D.S. Li, X.Q. Li, and T.S. Deng, Constitutive Modeling and Microstructure Change of Ti-6Al-4V During the Hot Tensile Deformation, J. Alloy. Compd., 2012, 541, p 346–352

N. Kotkunde, H.N. Krishnamurthy, P. Puranik, A.K. Gupta, and S.K. Singh, Microstructure Study and Constitutive Modeling of Ti-6Al-4V Alloy at Elevated Temperatures, Mater. Des., 2014, 54, p 96–103

J. Luo, M. Li, X. Li, and Y. Shi, Constitutive Model for High Temperature Deformation of Titanium Alloys Using Internal State Variables, Mech. Mater., 2010, 42(2), p 157–165

J.D. Eshelby, The Determination of the Elastic Field of an Ellipsoidal Inclusion, and Related Problems, Proc. R. Soc. Lond. A, 1957, 241, p 376–396

Tucker, III, L. Charles, and E. Liang, Stiffness Predictions for Unidirectional Short-Fiber Composites: Review and Evaluation, Compos. Sci. Technol., 1999, 59(5), p 655–671

Q. Bai, J. Lin, T.A. Dean, D.S. Balint, T. Gao, and Z. Zhang, Modelling of Dominant Softening Mechanisms for Ti-6Al-4V in Steady State Hot Forming Conditions, Mater. Sci. Eng. A, 2013, 559, p 352–358

X. Li and M. Li, A Set of Microstructure-Based Constitutive Equations in Hot Forming of a Titanium Alloy, J. Univ. Sci. Technol. Beijing, 2006, 13(5), p 435–441

R.C. Picu and A. Majorell, Mechanical Behavior of Ti-6Al-4V at High and Moderate Temperatures Part II: Constitutive Modeling, Mater. Sci. Eng. A, 2002, 326(2), p 306–316

S.L. Semiatin, F. Montheillet, G. Shen, and J.J. Jonas, Self-consistent Modeling of the Flow Behavior of Wrought Alpha/Beta Titanium Alloys Under Isothermal and Nonisothermal Hot-Working Conditions, Metall. Mater. Trans. A, 2002, 33(8), p 2719–2728

A. Paquin, H. Sabar, and M. Berveiller, Integral Formulation and Self-consistent Modelling of Elastoviscoplastic Behavior of Heterogeneous Materials, Arch. Appl. Mech., 1999, 69(1), p 14–35

P.M. Suquet, Overall Potentials and External Surfaces of Power Law or Ideally Plastic Composites, J. Mech. Phys. Solids, 1993, 41(6), p 981–1002

X.G. Fan, H. Yang, and P.F. Gao, Prediction of Constitutive Behavior and Microstructure Evolution in Hot Deformation of TA15 Titanium Alloy, Mater. Des., 2013, 51, p 34–42

R. Hill, A Self-consistent Mechanics of Composite Materials, J. Mech. Phys. Solids, 1965, 13, p 213–222

J. Liu, W. Zeng, Y. Lai, and Z. Jia, Constitutive Model of Ti17 Titanium Alloy with Lamellar-Type Initial Microstructure During Hot Deformation Based on Orthogonal Analysis, Mater. Sci. Eng. A, 2014, 597, p 387–394

X. Peng, H. Guo, Z. Shi, C. Qin, and Z. Zhao, Constitutive Equations for High Temperature Flow Stress of TC4-DT Alloy Incorporating Strain, Strain Rate and Temperature, Mater. Des., 2013, 50, p 198–206

H. Oikawa, K. Nishimura, and M.X. Cui, High-Temperature Deformation of Polycrystalline Beta Titanium, Scr. Mater., 1985, 19(7), p 825–828

H. Oikawa and T. Oomori, Steady State Deformation Characteristics of Alpha-Ti-Al Solid Solutions, Mater. Sci. Eng. A, 1988, A104, p 125–130

H. Li, X. Wang, D. Wei, J. Hu, and Y. Li, A Comparative Study on Modified Zerilli-Armstrong, Arrhenius-Type and Artificial Neural Network Models to Predict High-Temperature Deformation Behavior in T24 Steel, Mater. Sci. Eng. A, 2012, 536, p 216–222

X. Dong, S. Lu, H. Zheng, X. Li, and D. Ouyang, Cavity Nucleation During Hot Forging of Ti-6Al-2Zr-1Mo-1V Alloy with Colony Alpha Microstructure, Trans. Nonferrous Met. Soc. China, 2010, 20(12), p 2259–2264

H. Zhao, B. Wang, G. Liu, L. Yang, and W. Xiao, Effect of Vacuum Annealing on Microstructure and Mechanical Properties of TA15 Titanium Alloy Sheets, Trans. Nonferrous Met. Soc. China, 2015, 25(6), p 1881–1888

Acknowledgments

The authors acknowledge the support of the Beijing Laboratory of Metallic Materials and Processing for Modern Transportation. Helpful discussions with Prof. Jianguo Lin and Dr. Qian Bai of Imperial College and Dr. Kehuan Wang and Yong Wu of Harbin Institute of Technology are also greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Wang, B., Liu, G. et al. Hot Tensile Behavior and Self-consistent Constitutive Modeling of TA15 Titanium Alloy Sheets. J. of Materi Eng and Perform 24, 4647–4655 (2015). https://doi.org/10.1007/s11665-015-1784-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1784-7