Abstract

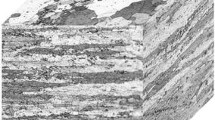

In this study, residual stresses after different quenching and aging processes of Al-Cu forged blocks were investigated by numerical simulation method and experimental measurements. An iterative zone-based heat transfer calculation was coupled with the hyperbolic sine-type constitutive model to simulate the residual stress during quenching process. The simulation results were compared with experiment data using both x-ray diffraction and crack compliance methods. The simulation results were in good agreement with the experimental measurements with around 9-13% deviation at the largest. Residual stress reduction can be achieved by decreasing the cooling rate during quenching. Quenching in water with different temperatures of 60, 80, and 100 °C resulted in the maximum compressive residual stress reduction of approximately 28.2, 75.7, and 88.9%, respectively, in Al-Cu alloy samples. When quenched in 10, 20, and 30% PAG solution, the reduction of maximum compressive residual stress in Al-Cu alloy samples was approximately 35.1, 47.8, and 53.2%, respectively. In addition, in order to study the amount of residual stress relief after aging treatments, aging treatments at 140 and 170 °C for different times were also studied. Aging treatment used to obtain the peak-aged (T6) and overaged (T7) condition produces only about 22.5 to 34.7% reduction in residual stresses.

Similar content being viewed by others

References

D.A. Tanner and J.S. Robinson, Reducing Residual Stress in 2014 Aluminium Alloy Die Forgings, Mater Des., 2008, 29, p 1489–1496

S.T. Amancio-Filho, S. Sheikhi, J.F. Dos Santos et al., Preliminary Study on the Microstructure and Mechanical Properties of Dissimilar Friction Stir Welds in Aircraft Aluminium Alloys 2024-T351 and 6056-T4, J. Mater. Process. Technol., 2008, 206, p 132–142

J.S. Robinson, D.A. Tanner, S. van Petegem, and A. Evans, Influence of Quenching and Aging on Residual Stress in Al-Zn-Mg-Cu Alloy 7449, Mater. Sci. Tech. Lond., 2012, 28, p 420–430

J.C. Williams and E.A. Starke, Progress in Structural Materials for Aerospace Systems, Acta Mater., 2003, 51, p 5775–5799

S. Nervi, B.A. Szabo, and K.A. Young, Prediction of Distortion of Airframe Components Made from Aluminum Plates, AIAA J., 2009, 47, p 1635–1641

M.B. Prime and M.R. Hill, Residual Stress, Stress Relief, and Inhomogeneity in Aluminum Plate, Scr. Mater., 2002, 46, p 77–82

G. Sanchez-Sarmiento, D.M. Coslia, C. Jouglard, et al., Residual Stresses, Distortion and Heat Transfer Coefficients of 7075 Aluminum Alloy Probes Quenched in Water and Polyalkylene Glycol Solutions, 20th ASM Heat Treating Society Conference and Show, St. Louis, 2000, p 1118–1124

J.S. Robinson, D.A. Tanner, S. van Petegem, and A. Evans, Influence of Quenching and Aging on Residual Stress in Al-Zn-Mg-Cu Alloy 7449, Mater. Sci. Technol. Lond., 2012, 28, p 420–430

X.W. Yang, Z.H. Lai, J.C. Zhu, Y. Liu, and D. He, Hot Compressive Deformation Behavior of the As-Quenched A357 Aluminum Alloy, Mater. Sci. Eng. B, 2012, 177, p 1721–1725

B. Xiao, K. Li, Q. Wang, and Y. Rong, Numerical Simulation and Experimental Validation of Residual Stresses in Water-Quenched Aluminum Alloy Castings, J. Mater. Eng. Perform., 2011, 20, p 1648–1657

A. Sugianto, M. Narazaki, M. Kogawara, and A. Shirayori, A Comparative Study on Determination Method of Heat Transfer Coefficient Using Inverse Heat Transfer and Iterative Modification, J. Mater. Process. Technol., 2009, 209, p 4627–4632

B. Xiao, Q. Wang, P. Jadhav, and K. Li, An Experimental Study of Heat Transfer in Aluminum Castings During Water Quenching, J. Mater. Process. Technol., 2010, 210, p 2023–2028

G.S. Schajer and M.B. Prime, Use of Inverse Solutions for Residual Stress Measurements, J. Eng. Mater., 2006, 128, p 375–382

M. Sedighi and C.A. McMahon, The Influence of Quenchant Agitation on the Heat Transfer Coefficient and Residual Stress Development in the Quenching of Steels, Proc. Inst. Mech. Eng. B, 2000, 214, p 555–567

N. Hatta, H. Fujimoto, K. Kinoshita, and H. Takuda, Experimental Study of Deformation Mechanism of a Water Droplet Impinging on Hot Metallic Surfaces Above the Leidenfrost Temperature, J. Fluid Eng., 1997, 119, p 692–699

A. Sugianto, M. Narazaki, and M. Kogawara, A Comparative Study on Determination Method of Heat Transfer Coefficient Using Inverse Heat Transfer and Iterative Modification, J. Mater. Process. Technol., 2009, 209, p 4627–4632

W. Liu, H. Zhao, D. Li et al., Hot Deformation Behavior of AA7085 Aluminum Alloy During Isothermal compRession at Elevated Temperature, Mater. Sci. Eng. A, 2014, 596, p 176–182

B.Y. Dong, Z.W. Shao, T.J. Jiang, Y.B. Zhang, and L. Zhen, Minimization of Residual Stress in an Al-Cu Alloy Forged Plate by Different Heat Treatments, J Mater Eng Perform, 2015. doi:10.1007/s11665-015-1505-2

J.S. Robinson, D.A. Tanner, and C.E. Truman, 50th Anniversary Article: The Origin and Management of Residual Stress in Heat-Treatable Aluminium Alloys, Strain, 2014, 50, p 185–207

J.F. Chen, J.T. Jiang, L. Zhen, and W.Z. Shao, Stress Relaxation Behavior of an Al-Zn-Mg-Cu Alloy in Simulated Age-Forming Process, J. Mater. Process. Technol., 2014, 214, p 775–783

Acknowledgments

This work was financially supported by the Natural Science Foundation of China (No. 51171051).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, YB., Shao, WZ., Lu, LX. et al. Numerical Simulation of Residual Stress in an Al-Cu Alloy Block During Quenching and Aging. J. of Materi Eng and Perform 24, 4928–4940 (2015). https://doi.org/10.1007/s11665-015-1758-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1758-9