Abstract

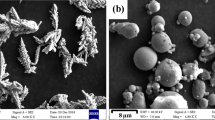

Fly ash cenosphere/AZ91D Mg alloy (FAC/AZ91D) composites were prepared using stir casting method. The effects of the applied load, the wearing time, and the diameter and the content of fly ash cenosphere on the wear behavior of the composites were investigated under dry sliding condition. The results showed the wear resistance of FAC/AZ91D composites is generally better than that of AZ91D Mg alloy. The mass fraction and diameter of FAC have important effects on the wear resistance of the composites, and the wear resistance of the composites is excellent when the mass fraction and diameter of FAC are moderate. When the mass fraction and diameter of FAC are more than the critical values, the wear resistance of the composites lowers again. The wear resistance of the composites decreases with the increase in the applied load. The relationship between the worn mass loss and the applied load is nonlinear. When the applied load is smaller, the worn mass loss of the composites increases rapidly with the increase of the applied load. These research results show that the composites have broad application prospects under dry sliding wear condition, and they can provide guidance for the selection of the raw materials, the structure design, and the application conditions of the composites.

Similar content being viewed by others

References

M. Hajiali Fini and A. Amadeh, Improvement of Wear and Corrosion Resistance of AZ91 Magnesium Alloy by Applying Ni-SiC Nanocomposite Coating Via Pulse Electrodeposition, Trans. Nonferrous Met. Soc. China, 2013, 23, p 2914–2922

Z.W. Song, G. Yu, Z.H. Xie, B.N. Hu, X.M. He, and X.Y. Zhang, Performance of Composite Coating on AZ31B Magnesium Alloy Prepared by Anodic Polarization and Electroless Electrophoresis Coating, Surf. Coat. Technol., 2014, 242(15), p 83–91

X.J. Wang, N.Z. Wang, L.Y. Wang, X.S. Hu, K. Wu, Y.Q. Wang, and Y.D. Huang, Processing, Microstructure and Mechanical Properties of Micro-SiC Particles Reinforced Magnesium Matrix Composites Fabricated by Stir Casting Assisted by Ultrasonic Treatment Processing, Mater. Des., 2014, 57, p 638–645

X.Z. Zhang, Q. Zhang, and H. Hu, Tensile Behaviour and Microstructure of Magnesium AM60-Based Hybrid Composite Containing Al2O3 Fibres and Particles, Mater. Sci. Eng., 2014, A607, p 269–276

Z.Q. Huang and S.R. Yu, Microstructure Characterization on the Formation of In Situ Mg2Si and MgO Reinforcements in AZ91D/Fly Ash Composites, J. Alloys Compd., 2011, 509(2), p 311–315

C.D. Li, X.J. Wang, W.Q. Liu, H.L. Shi, C. Ding, X.S. Hu, M.Y. Zheng, and K. Wu, Effect of Solidification on Microstructures and Mechanical Properties of Carbon Nanotubes Reinforced Magnesium Matrix Composite, Mater. Des., 2014, 58, p 204–208

P.K. Rohatgi, R.Q. Guo, and B.N. Keshavaram, Cast Aluminium Alloy-Fly Ash Composites, Key Eng. Mater., 1995, 104–107, p 283–292

P.K. Rohatgi, Low-Cost, Fly-Ash-Containing Aluminum-Matrix Composites, JOM, 1994, 46, p 55–59

P.K. Rohatgi, R.Q. Guo, H. Iksan, and R. Asthana, Pressure Infiltration Technique for Synthesis of Aluminum-Fly Ash Particulate Composite, Mater. Sci. Eng., 1998, A244, p 22–30

P.K. Rohatgi, J.K. Kim, N. Gupta, A. Simon, and A. Daoud, Compressive Characteristics of A356/Fly Ash Cenosphere Composites Synthesized by Pressure Infiltration Technique, Composites A, 2006, 37(3), p 430–437

A. Moutsatsou, G. Itskos, P. Vounatsos, N. Koukouzas, and C. Vasilatos, Microstructural Characterization of PM-Al and PM-Al/Si Composites Reinforced with Lignite Fly Ash, Mater. Sci. Eng., 2010, A527, p 4788–4795

S. Zahi and A.R. Daud, Fly Ash Characterization and Application in Al-based Mg Alloys, Mater. Des., 2011, 32(3), p 1337–1346

A. Daoud, M.T. Abou El-Khair, A.Y. Shenouda, E. Mohammed, and P.K. Rohatgi, Microstructure, Tensile Properties and Electrochemical Behavior of Pb Alloy-45 vol.% Fly Ash Microballoon Composites, Mater. Sci. Eng., 2009, A526, p 225–234

P.K. Rohatgi, A. Daoud, B.F. Schultz, and T. Puri, Microstructure and Mechanical Behavior of Die Casting AZ91D-Fly Ash Cenosphere Composites, Composites A, 2009, 40, p 883–896

A. Daoud, M.T. Abou El-khair, M. Abdel-Aziz, and P.K. Rohatgi, Fabrication, Microstructure and Compressive Behavior of ZC63Mg-Microballoon Foam Composites, Compos. Sci. Technol., 2007, 67(9), p 1842–1853

P.K. Rohatgi, R.Q. Guo, P. Huang, and S. Ray, Friction and Abrasion Resistance of Cast Aluminum Alloy-Fly Ash Composites, Metall. Mater. Trans., 1997, 28, p 245–250

T.P.D. Rajan, R.M. Pillai, B.C. Pai, K.G. Satyanarayana, and P.K. Rohatgi, Fabrication and Characterisation of Al-7Si-0.35 Mg/Fly Ash Metal Matrix Composites Processed by Different Stir Casting Routes, Compos. Sci. Technol., 2007, 67, p 3369–3377

E. Marin, M. Lekka, F. Andreatta, L. Fedrizzi, G. Itskos, A. Moutsatsou, N. Koukouzas, and N. Kouloumbi, Electrochemical Study of Aluminum-Fly Ash Composites Obtained by Powder Metallurgy, Mater. Charact., 2012, 69, p 16–30

I. Narasimha Murthy, D. Venkata Rao, and J. Babu Rao, Microstructure and Mechanical Properties of Aluminum-Fly Ash Nanocomposites Made by Ultrasonic Method, Mater. Des., 2012, 35, p 55–65

J. David Raja Selvam, D.S. Robinson Smart, and I. Dinaharan, Microstructure and Some Mechanical Properties of Fly Ash Particulate Reinforced AA6061 Aluminum Alloy Composites Prepared by Compocasting, Mater. Des., 2013, 49, p 28–34

A. Daoud, Effect of Fly Ash Addition on the Structure and Compressive Properties of 4032-Fly Ash Particle Composite Foams, J. Alloys Compd., 2009, 487, p 618–625

Sudarshan and M.K. Surappa, Dry Sliding Wear of Fly Ash Particle Reinforced A356 Al Composites, Wear, 2008, 265, p 349–360

P.L. Menezesa and S.V. Kailas, Influence of Surface Texture and Roughness Parameters on Friction and Transfer Layer Formation during Sliding of Aluminium Pin on Steel Plate, Wear, 2009, 267, p 1534–1549

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24, p 981–988

Z.Q. Huang, Preparation and Properties of the AZ91D Mg Alloy-Cenosphere Composites, The Doctor Thesis of Jilin University, Changchun, 2012, p 5 [in Chinese]

P.R.S. Kumar, S. Kumaran, T. Srinivasa Rao, and S. Natarajan, High Temperature Sliding Wear Behavior of Press-Extruded AA6061/Fly Ash Composite, Mater. Sci. Eng., 2010, A527, p 1501–1509

G. Itskos, P.K. Rohatgi, A. Moutsatsou, J.D. DeFouw, N. Koukouzas, C. Vasilatos, and B.F. Schultz, Synthesis of A356 Al-high-Ca Fly Ash Composites by Pressure Infiltration Technique and Their Characterization, J. Mater. Sci., 2012, 47, p 4042–4052

D. Singla and S.R. Mediratta, Effect of Load and Speed on Wear Properties of Al7075-Fly Ash Composite Material, Int. J. Innov. Res. Sci. Eng. Technol., 2013, 2(5), p 1–9

Acknowledgments

This work was supported by “the Key Grant Project of Chinese Ministry of Education (No. 313056),” “Doctoral Program of Higher Education of the Ministry of Education of the Special Research Fund (20110133110003),” “Project for the Natural Science Funds of Heilongjiang province (E201467),” and “Project for Science and Technology of Education Department of Heilongjiang province (12511535).”

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yu, S.R., Huang, Z.Q. Dry Sliding Wear Behavior of Fly Ash Cenosphere/AZ91D Mg Alloy Composites. J. of Materi Eng and Perform 23, 3480–3488 (2014). https://doi.org/10.1007/s11665-014-1157-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1157-7