Abstract

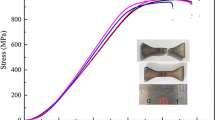

The microstructure and mechanical properties in the pulsed laser beam welded joints of Ti-2Al-1.5Mn titanium alloy thin sheet were investigated in this study. The results show that the original α + β-phases and the transformed α + α′-phases are found in the partially transformed heat-affected zone (HAZ) together with the remaining β-phase, and the microhardness gradually enhances in the region as the result of the increase of α′-phase. The martensitic α′-phase and the remaining β-phase are detected in the fully transformed HAZ and the fusion zone (FZ), and the highest microhardness is found in these regions in virtue of the dominant α′-phase structure. The fine α′-phase appeared in the FZ results in higher average microhardness at high welding speed. Moreover, similar to the results of microhardness test, the tensile test results mean that the HAZ and FZ are stronger than the base metal (BM). Therefore, pulsed laser beam welding is feasible for joining thin sheet of Ti-2Al-1.5Mn titanium alloy.

Similar content being viewed by others

References

C. Leyens and M. Peters, Titanium and Titanium Alloys: Fundamentals and Applications, Wiley-VCH, Weinheim, 2003

N. Poondla, T.S. Srivatsan, A. Patnaik, and M. Petraroli, A Study of the Microstructure and Hardness of Two Titanium Alloys: Commercially Pure and Ti-6Al-4 V, J. Alloys Compd., 2009, 486, p 162–167

W.A. Baeslack III, J.R. Davis, and C.E. Cross, Selection and Weldability of Conventional Titanium Alloys, ASM Handbook, Vol 6, Welding brazing and soldering, ASM International, Materials Park, OH, 1993, p 507–523

A.B. Short, Gas Tungsten Arc Welding of α + β Titanium Alloys: A Review, Mater. Sci. Technol., 2009, 25, p 09–324

T.S. Balasubramanian, V. Balasubramanian, and M.A. Muthumanikkam, Fatigue Performance of Gas Tungsten Arc, Electron Beam, and Laser Beam Welded Ti-6Al-4 V Alloy Joints, J. Mater. Eng. Perform., 2011, 20, p 1620–1630

X.L. Gao, L.J. Zhang, J. Liu, and J.X. Zhang, A Comparative Study of Pulsed Nd: YAG Laser Welding and TIG Welding of Thin Ti6Al4 V Titanium Alloy Plate, Mater. Sci. Eng. A, 2013, 559, p 14–21

P.Q. Xu, L.J. Li, and C.B. Zhang, Microstructure Characterization of Laser Welded Ti-6AL-4 V Fusion Zones, Mater. Charact., 2014, 87, p 179–185

X. Li, J. Xie, and Y. Zhou, Effects of Oxygen Contamination in the Argon Shielding Gas in Laser Welding of Commercially Pure Titanium Thin Sheet, J. Mater. Sci., 2005, 40, p 3437–3443

E. Akman, A. Demir, T. Canel, and T. Sinmazcelik, Laser Welding of Ti6Al4 V Titanium Alloys, J. Mater. Process. Technol., 2009, 209, p 3705–3713

F. Caiazzo, F. Curcio, G. Daurelio, and F. Memola, Capece Minutolo, Ti6Al4 V Sheets Lap and Butt Joints Carried Out by CO2 Laser: Mechanical and Morphological Characterization, J. Mater. Process. Technol., 2004, 149, p 546–552

A.S.H. Kabir, X. Cao, J. Gholipour, P. Wanjara, J. Cuddy, A. Birur, and M. Medraj, Effect of Postweld Heat Treatment on Microstructure, Hardness, and Tensile Properties of Laser-Welded Ti-6Al-4 V, Metall. Mater. Trans. A, 2012, 42, p 4171–4184

T. Mohandas, D. Banerjee, Y.R. Mahajan, and V.V. Kutumba Rao, Studies on Fusion Zone Fracture Behaviour of Electron Beam Welds of an α + β Titanium Alloy, J. Mater. Sci., 1996, 31, p 3769–3775

W. Lu, Y.W. Shi, X.Y. Li, and Y.P. Lei, Correlation Between Tensile Strength and Hardness of Electron Beam Welded TC4-DT Joints, J. Mater. Eng. Perform., 2013, 22, p 1694–1700

L. Zhou, H.J. Liu, P. Liu, and Q.W. Liu, The Stir Zone Microstructure and Its Formation Mechanism in Ti-6Al-4 V Friction Stir Welds, Scripta Mater., 2009, 61, p 596–599

C. Li, K. Muneharua, S. Takao, and H. Kouji, Fiber Laser-GMA Hybrid Welding of Commercially Pure Titanium, Mater. Des., 2009, 30, p 109–114

F. Malek Ghaini, M.J. Hamedi, M.J. Torkamany, and J. Sabbaghzadeh, Weld Metal Microstructure Characteristics in Pulsed Nd: YAG Laser Welding, Scr. Mater., 2007, 56, p 955–958

E. Assuncao and S. Williams, Comparison of Continuous Wave and Pulsed Wave Laser Welding Effects, Opt. Laser Eng., 2013, 51, p 674–680

Y.F. Tzeng, Process Characterisation of Pulsed Nd:YAG Laser Seam Welding, Int. J. Adv. Manuf. Technol., 2000, 16, p 10–18

A.V. Vicente, R.B. Jose, and R. Wagner, Pulsed Nd: YAG Laser Seam Welding of AISI, 316L Stainless Steel Thin Foils, J. Mater. Process. Technol., 2010, 210, p 1838–1843

M.J. Torkamany, M.J. Hamedi, F. Malek, and J. Sabbaghzadeh, The Effect of Process Parameters on Keyhole Welding with a 400 W Nd :YAG Pulsed Laser, J. Phys. D, 2006, 39, p 4563–4567

F. Javidrad, H. Farghadani, and M. Hedari, The MPAW of Ti-3Al-2.5 V Thin Sheets and Its Effects on Mechanical and Microstructural Properties, J. Mater. Eng. Perform., 2013, doi:10.1007/s11665-013-0785-7

M.J. Donachie, Titanium: A Technical Guide, ASM International Metals Park, Ohio, 1988

A. Costa, R. Miranda, L. Quintino, and D. Yapp, Analysis of Beam Material Interaction in Welding of Titanium with Fiber Lasers, Mater. Manuf. Process., 2007, 22, p 798–803

J.W. Elmer, T.A. Palmer, S.S. Babu, W. Zhang, and T. DebRoy, Phase Transformation Dynamics During Welding of Ti-6Al-4 V, J. Appl. Phys., 2004, 95, p 8327–8339

R.M. Miranda, G. Lopes, L. Quintino, J.P. Rodrigues, and S. Williams, Rapid Prototyping with High Power Fiber Lasers, Mater. Des., 2008, 29, p 2072–2075

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, X., Liu, H. & Zhang, J. Microstructure and Mechanical Properties of Pulsed Laser Beam Welded Ti-2Al-1.5Mn Titanium Alloy Joints. J. of Materi Eng and Perform 23, 1973–1980 (2014). https://doi.org/10.1007/s11665-014-1002-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1002-z