Abstract

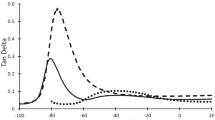

Shape-memory polymers are materials that are capable of changing their shape when an external stimulus is applied. This effect is called the shape-memory effect (SME) and takes place by means of a thermomechanical cycle called programming. The SME depends on the thermomechanical conditions at which programming is performed, and the influence of these conditions differs depending on whether the programming is performed with a strain- or stress-controlled protocol. This study focuses on finding the thermomechanical cycling conditions in stress-controlled programming (T prog and σm) that stabilize the material in the fewest cycles while obtaining the best mechanical and shape-memory properties over the highest number of cycles. Using a T prog above or below, the glass transition temperature makes a big difference in terms of shape recovery and the maximum stress is a key factor in the stabilization of shape-memory properties.

Similar content being viewed by others

References

C. Liu, H. Qin, and P.T. Mather, Review of Progress in Shape-Memory Polymers, J. Mater. Chem., 2007, 17(16), p 1543–1558

A. Lendlein and S. Kelch, Shape-Memory Polymers, Angew. Chem. Int. Ed., 2002, 41(12), p 2034–2057

R. Mohr, K. Kratz, T. Weigel, M. Lucka-Gabor, M. Moneke, and A. Lendlein, Initiation of Shape-Memory Effect by Inductive Heating of Magnetic Nanoparticles in Thermoplastic Polymers, Proc. Natl. Acad. Sci. USA, 2006, 103(10), p 3540–3545

A.J.W. McClung, G.P. Tandon, and J.W. Baur, Deformation Rate-, Hold Time-, and Cycle-Dependent Shape-Memory Performance of Veriflex-E Resin, Mech. Time-Depend. Mater., 2011, 17, p 39–52

V.A. Beloshenko, V.N. Varyukhin, and Y.V. Voznyak, The Shape Memory Effect in Polymers, Usp. Khim., 2005, 74(3), p 285–306

C. Schmidt, K. Neuking, and G. Eggeler, Functional Fatigue of Shape-Memory Polymers, in Materials Research Society Symposium Proceedings, San Francisco, CA, 2009, vol. 1190, pp. 43–48

F. Castro, K.K. Westbrook, K.N. Long, R. Shandas, and H.J. Qi, Effects of Thermal Rates on the Thermomechanical Behaviors of Amorphous Shape Memory Polymers, Mech. Time-Depend. Mater., 2010, 14(3), p 219–241

A.J.W. McClung, G.P. Tandon, and J.W. Baur Air, Fatigue Cycling of Shape Memory Polymer Resin, 2011, vol. 3, pp. 119–127.

J.L. Hu, F.L. Ji, and Y.W. Wong, Dependency of the Shape Memory Properties of a Polyurethane upon Thermomechanical Cyclic Conditions, Polym. Int., 2005, 54(3), p 600–605

C. Schmidt, A.M.S. Chowdhury, K. Neuking, and G. Eggeler, Stress-Strain Behavior of Shape Memory Polymers by 1WE Method: Application to Tecoflex®, J. Macromol. Sci. A, 2011, 48(3), p 204–210

A.J.W. McClung, G.P. Tandon, and J.W. Baur, The Strain Rate- and Temperature-Dependent Mechanical Behavior of Veriflex-E in tension, in ASME 2010 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, SMASIS 2010, Philadelphia, PA, 2010, vol. 1, pp. 69–78.

J. Cui, K. Kratz, M. Heuchel, B. Hiebl, and A. Lendlein, Mechanically Active Scaffolds from Radio-Opaque Shape-Memory Polymer-Based Composites, Polym. Adv. Technol., 2011, 22(1), p 180–189

H. Tobushi, H. Hara, E. Yamada, and S. Hayashi, Thermomechanical Properties in a Thin Film of Shape Memory Polymer of Polyurethane Series, Smart Mater. Struct., 1996, 5(4), p 483–491

S. Mogharebi, R. Kazakeviciute-Makovska, H. Steeb, G. Eggeler, and K. Neuking, On the Cyclic Material Stability of Shape Memory Polymer, Mater. wis. Werkstofftech., 2013, 44(6), p 521–526

B. Atli, F. Gandhi, and G. Karst, Thermomechanical Characterization of Shape Memory Polymers, in Proceedings of SPIE—The International Society for Optical Engineering, San Diego, CA, 2007, vol. 6524

J. Cui, K. Kratz, and A. Lendlein, Adjusting Shape-Memory Properties of Amorphous Polyether Urethanes and Radio-Opaque Composites Thereof by Variation of Physical Parameters during Programming, Smart Mater. Struct., 2010, 19(6), p 065019

S. Farzaneh, J. Fitoussi, A. Lucas, M. Bocquet, and A. Tcharkhtchi, Shape Memory Effect and Properties Memory Effect of Polyurethane, J. Appl. Polym. Sci., 2013, 128(5), p 3240–3249

Acknowledgment

The authors would like to thank MINECO (MAT2011-27039-C03-01, MAT2011-27039-C03-02) for giving financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santiago, D., Ferrando, F. & De la Flor, S. Effect of Different Shape-Memory Processing Methods on the Thermomechanical Cyclic Properties of a Shape-Memory Polyurethane. J. of Materi Eng and Perform 23, 2561–2566 (2014). https://doi.org/10.1007/s11665-014-0983-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-0983-y