Abstract

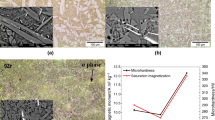

Effects of small addition of Zr on the microstructures and properties of as-cast Cu50Ag46−xZrxTi4 alloys were investigated by differential scanning calorimeter (DSC), x-ray diffraction, microscope, and property testings. The results show that the melting point of the Cu50Ag46Ti4 alloys does not change obviously with the addition of Zr at the melting points of about 779 °C. Adding Zr reduces the volume fraction and size of the board strips of Cu3Ti phase, promotes the uniform distribution of the new phase Cu4AgZr, and improves the Vickers hardness and shear strength of the based alloys. Moreover, increasing the Zr content can improve the high-temperature oxidation resistance of alloys.

Similar content being viewed by others

Reference

Y.V. Bykov, K.I. Rybakov, and V.E. Semenov, High-temperature microwave processing of materials, J. Phys. D., 2001, 34, p 55–75

W. Tillmann, E. Lugscheider, K. Schlimbach, C. Manter, and J.E. Indacochea, Heat-resistant active brazing of silicon nitride part 2: metallurgical characterization of the braze joint, Weld. J., 1998, 77, p 103–109

P.O. Santacreu, J.L. Koutny, J.D. Bartout, Y. Bienvenu, and C. Colin, Study of the reactive brazing of a silicon nitride to steel using ternary Ag–Cu–Ti: microstructures and mechanical strength of the bonds, Mater. High Temp., 1994, 12, p 293–299

A.H. ElSawy and M.F. Fahmy, Brazing of Si3N4 ceramic to copper, J. Mater. Process. Technol., 1998, 77, p 266–272

M. Paulasto and J.K. Kivilahti, Formation of interfacial microstructure in brazing of Si3N4 with Ti-activated Ag–Cu filler alloys, Scripta Metall. Mater., 1995, 32, p 1209–1214

A.H. Carim and R.E. Loehman, Microstructure at the interface between AlN and a Ag–Cu–Ti braze alloy, J. Mater. Res., 1990, 5, p 1520–1529

G.B. Lin, J.H. Huang, and H. Zhang, Joints of carbon fiber-reinforced SiC composites to Ti-alloy brazed by Ag–Cu–Ti short carbon fibers, J. Mater. Process. Technol., 2007, 189, p 256–261

M. Paulasto and J. Kivilahti, Metallurgical reaction controlling the brazing of Al2O3 with Ag–Cu–Ti filler alloys, J. Mater., 1998, 13, p 343–352

R.K. Shiue, S.K. Wu, and C.H. Chan, The interfacial reactions of infrared brazing Cu and Ti with two silver-based braze alloys, J. Alloys Compd., 2004, 372, p 148–157

A. Ghosh and A.K. Chattopadhyay, Performance enhancement of single-layer miniature cBN wheels using CFUBMS- deposited tin coating, Int. J. Mach. Tool. Manu., 2007, 47, p 1799–1803

M. Inoue, K. Yasuda, T. Ito, T. Sasahara, M. Yokota, and A. Nakahira, Fabrication of sintered diamond/metal composites and evaluation of grinding performance for sapphire, Mater. Sci. Appl., 2012, 3, p 619–623

E. Saiz, R.M. Cannon, and A.P. Tomsia, Reactive spreading: adsorption, ridging and compound formation, Acta Mater., 2000, 48, p 4449–4462

A.K. Vasudevan, E.A. Ludwiczak, and S.F. Baumann, Grain boundary fracture in Al–Li alloys, Mater. Sci. Technol., 1986, 2, p 1205–1208

M. Puiggali, A. Zielinski, J.M. Olive, E. Renauld, D. Desjardins, and M. Cid, Effect of microstructure on stress corrosion cracking of an Al–Zn–Mg–Cu alloy, Corros. Sci., 1998, 40, p 805–819

R.J. Fruehan, The effect of zirconium, cerium, and lanthanum on the solubility of oxygen in liquid iron, Metall. Trans., 1973, 5, p 345–347

A.K. Vasudevan, M.A. Przystupa, and W.G. Fricke, Jr., Texture-microstructure effects in yield strength anisotropy of 2090 sheet alloys, Mater. Sci. Eng. A, 1996, 208, p 172–180

A. Gaganov, J. Freudenberger, E. Botcharova, and L. Schultz, Effect of Zr additions on the microstructure, and the mechanical and electrical properties of Cu–7 wt.%Ag alloys, Mater. Sci. Eng. A, 2006, 437, p 313–322

L. Li, J. W. Jang, B. Allmen, Shear property and microstructure evaluation of Pb-free solder bumps under room temperature and multiple reflow/high temperature aging, Adv. Pack. Mater., 2001, p 347–353

I.S. Batra, G.K. Dey, U.D. Kulkarni, and S. Banerjee, Microstructure and properties of Cu–Cr–Zr alloy, J. Nuclear. Mater., 2001, 299, p 91–100

S. Suenaga, M. Koyama, S. Arai, and M. Nakahashi, Solid-state reaction of the Ag–Cu–Ti thin film-Al2O3 substrate system, J. Mater., 1993, 8, p 1805–1811

O. Dezellus, R. Arroyave, and S.G. Fries, Thermodynamic modeling of the Ag–Cu–Ti ternary system, Int. J. Mater. Res., 2011, 3, p 286–297

L.S. Guinesi and E.T.G. Cavalheiro, The use of DSC curves to determine the acetylation degree of chitin/chitosan samples, Thermochim. Acta, 2006, 444, p 128–133

E.A. Polman, T. Fransen, and P.J. Gellings, The reactive element effect: ionic processes of grain boundary segregation and diffusion in chromium oxide scales, J. Phys. Condens. Mater., 1989, 1, p 4497–4510

Acknowledgment

This work is supported by National Natural Science Foundation of China (No. 51271152 and 51301206), Hunan Provincial Natural Science Foundation (No. 13JJ6006), and National Key Fundamental Research Project of China (2011CB605803).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, D.H., Li, X.X., Zhang, F.Q. et al. Effect of Zr Addition on Microstructure and Properties of Cu–Ag–Ti Alloys. J. of Materi Eng and Perform 23, 1854–1860 (2014). https://doi.org/10.1007/s11665-014-0926-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-0926-7