Abstract

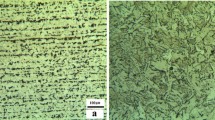

Carbonitrided low-carbon steels are resistance welded in various engineering components. However, there are no reports on the microstructure and mechanical properties of their resistance spot welding (RSW) joints. Therefore, various carbonitridings were performed on the low-carbon steel sheets, and then various RSWs were applied to these carbonitrided sheets. The metallurgical and mechanical properties of the welding joint were investigated and discussed. The peak load and failure energy increased with the increases of welding current and fusion zone (FZ) size. At 11 kA welding current, the carbonitrided steel joint had the failure energy of 16 J, i.e., approximately 84 pct of untreated steel joint. FZ of carbonitrided steel joint consisted of ferrite, Widmanstatten ferrite, and untempered martensite, i.e., the solid-state transformation products, while the microstructure at the outer surfaces consisted of untempered martensite and retained austenite. The surface hardening of carbonitrided steel after RSW could be maintained, i.e., approximately 810 HV. The results can be applied to carbonitriding and RSW to achieve a good welding joint.

Similar content being viewed by others

References

J.R. Davis, ed.: ASM Handbook, Heat Treating, vol. 4, ASM International, Materials Park, 1994.

B. Selçuk, R. Ipek, and M.B. Karamiş: J. Mater. Process. Technol., 2003, vol. 141, pp. 189–96.

C. Kanchanomai and W. Limtrakarn: J. Mater. Eng. Perform., 2008, vol. 17, pp. 879–87.

M. Pouranvari and S.P.H. Marashi: Sci. Technol. Weld. Join., 2013, vol. 18, pp. 361–403.

S. Aslanlar, A. Ogur, U. Ozsarac, and E. Ilhan: Mater. Des., 2008, vol. 29, pp. 1427–31.

X.P. Wang, Y.Q. Zhang, J.B. Ju, J.Q. Zhang, and J.W. Yang: J. Iron Steel Res. Int., 2016, vol. 23, pp. 1104–10.

D. Deng: Mater. Des., 2009, vol. 30, pp. 359–66.

L. Cui, H. Fujii, N. Tsuji, and K. Nogi: Scripta Mater., 2007, vol. 56, pp. 637–40.

T. Ogawa, K. Suzuki, and T. Zaizen: Weld. J., 1984, vol. 63, pp. 213–23.

M. Vedani, B. Previtali, G.M. Vimercati, A. Sanvito, and G. Somaschini: Surf. Coat. Technol., 2007, vol. 201, pp. 4518–25.

JIS G 3131: Hot-Rolled Mild Steel Plates, Sheets, and Strips, Japanese Industrial Standards, 2010.

R. Davies and C.G. Smith: Heat Treat. Met., 1978, vol. 5, pp. 3–10.

N. Taweejun and C. Kanchanomai: J. Mater. Eng. Perform., 2015, vol. 24, pp. 4853–62.

M. Pouranvari, S.M. Mousavizadeh, S.P.H. Marashi, M. Goodarzi, and M. Ghorbani: Mater. Des., 2011, vol. 32, pp. 1390–8.

AWS D8.9M: Test Methods for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials, American Welding Society, 2012.

H.S. Choi, G.H. Park, W.S. Lim, and B.M. Kim: J. Mech. Sci. Technol., 2011, vol. 25, pp. 1543–50.

G. Krauss: Mater. Sci. Eng. A, 1999, vol. 273–275, pp. 40–57.

M. Pouranvari: Int. J. Multidiscip. Sci. Eng., 2011, vol. 2, pp. 63–7.

M. Pouranvari: Arch. Metall. Mater., 2013, vol. 58, pp. 67–72.

S. Dancette, V. Massardier, J. Merlin, D. Fabrègue, and T. Dupuy: 6th Int. Conf. Process. Manuf. Adv. Mater., THERMEC’2009, 2010, pp. 130–35.

S. Dancette, D. Fabrègue, V. Massardier, J. Merlin, T. Dupuy, and M. Bouzekri: Eng. Fract. Mech., 2011, vol. 78, pp. 2259–72.

A.A. Mottahedi and M. Mottahedi: 12th Int. Conf. Fract., ICF-122009, 2009, pp. 7340–46.

I. Mitelea and C.M. Craciunescu: Mater. Des., 2010, vol. 31, pp. 2181–6.

L. Zhao, Z.I. Tian, Y. Peng, Y. Qi, and Y.J. Wang: J. Iron Steel Res. Int., 2007, vol. 14, pp. 259–62.

Acknowledgments

The authors would like to acknowledge the support from Dr. Patiphan Juijerm (Kasetsart University, Thailand), the Thailand Research Fund, the Thailand Commission on Higher Education of Thailand (National Research University Project), the National Research Council of Thailand (NRCT), and the National Metal and Materials Technology Center (MTEC, Thailand).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 10, 2016.

Rights and permissions

About this article

Cite this article

Taweejun, N., Poapongsakorn, P. & Kanchanomai, C. Microstructure and Mechanical Properties of Resistance Spot Welding Joints of Carbonitrided Low-Carbon Steels. Metall Mater Trans B 48, 1174–1187 (2017). https://doi.org/10.1007/s11663-017-0927-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-0927-7