Abstract

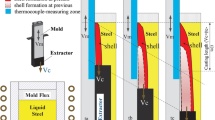

Various kinds of surface defects on the continuous casting slab usually originate from nonuniform heat transfer and mechanical behavior, especially during the initial solidification inside the mold. In this article, a model-coupled inverse heat transfer problem incorporating the effect of slag layers and air gap is developed to study the nonuniform distribution of liquid slag, solid slag, and air gap layers. The model considers not only the formation and evolution of slag layers and air gap but also the temperatures in the mold copper as measured by thermocouples. The simulation results from the model and the measured temperatures from experiments are shown to be in good agreement with each other. At the casting speed of 0.65 m/min, the liquid slag film disappears and transforms into solid slag entirely at about 400 mm away from meniscus, and an air gap begins to form. Until the mold exit, the maximum thickness of the solid slag layer and air gap gradually increases to 1.34 and 0.056 mm, respectively. The results illustrate that the magnitude and nonuniform distribution of the slag layers and air gap along the cross direction, correlating with heat flux between the shell and mold, eventually determine the temperature profiles of the mold hot face and slab surface. The proposed model may provide a convenient approach for analyzing nonuniform heat transfer and mechanical behaviors between the mold and slab in the real casting process.

Similar content being viewed by others

References

Y. Meng and B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 685-703.

R.B. Mahapatra, J.K. Brimacombe, and I.V. Samarasekera: Metall. Mater. Trans. B, 1991, vol. 22B, pp. 875-88.

B.G. Thomas, G. Li, A. Moitra, and D. Habing: Analysis of Thermal and Mechanical Behavior of Copper Molds during Continuous Casting of Steel Slabs, 80th Steelmaking Conference, Chicago, IL, 1997.

Z.Z. Cai and M.Y. Zhu: Acta Metall. Sin., 2011, vol. 47, no. 6, pp. 678-87.

X.D. Wang, L. Tang, X.Y. Zang, and M. Yao: J. Mater. Process. Technol., 2012, vol. 212, pp. 1811-8.

L. Tang, M. Yao, X.D. Wang, and X.B. Zhang: Steel Res. Int., 2012, vol. 83, no. 12, pp. 1203-13.

J. Cho, H. Shibata, T. Emi, and M. Suzuki: ISIJ. Int., 1998, vol. 38, no. 5, pp. 440-6.

A. Yamauchi, K. Sorimachi, T. Sakuraya, and T. Fujii: ISIJ. Int., 1993, vol. 33, no. 1, pp. 140-7.

H. Nakada, M. Susa, Y. Seko, M. Hayashi, and K. Nagata: ISIJ. Int., 2008, vol. 48, no. 4, pp. 446-53.

R. Saraswat, D.M. Maijer, P.D. Lee, and K.C. Mills: ISIJ. Int., 2007, vol. 47, no. 1, pp. 95-104.

P.E. Ramirez-Lopez, P.D. Lee, and K.C. Mills: ISIJ. Int., 2010, vol. 50, no. 3, pp. 425-34.

Y. Meng and B.G. Thomas: ISIJ. Int., 2006, vol. 46, no. 5, pp. 660-9.

S. Ozawa, M. Suza, Y. Goto, R.K. Endo, and K.C. Mills: ISIJ. Int., 2006, vol. 46, no. 3, pp. 413-9.

J. Cho, H. Shibata, T. Emi, and M. Suzuki: ISIJ. Int., 1998, vol. 38, no. 3, pp. 268-75.

A. Yamauchi, T. Emi, and S. Seetharaman: ISIJ. Int., 2002, vol. 42, no. 10, pp. 1084-93.

Y. Meng and B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 707-25.

Acknowledgments

We would like to acknowledge the financial support of the National Natural Science Foundation of China (51004021/51474047). This Project was granted financial support from the China Postdoctoral Science Foundation (2012M520621/2013T60511). Also, the support of the Fundamental Research Funds for the Central Universities and of the Key Laboratory of Solidification Control and Digital Preparation Technology (Liaoning Province) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 1, 2015.

Rights and permissions

About this article

Cite this article

Wang, X., Kong, L., Yao, M. et al. Novel Approach for Modeling of Nonuniform Slag Layers and Air Gap in Continuous Casting Mold. Metall Mater Trans B 48, 357–366 (2017). https://doi.org/10.1007/s11663-016-0778-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0778-7