Abstract

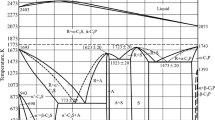

In the present study, the dephosphorization of Fe-Ni-Si melt by CaO-saturated CaO-CaF2 slag was investigated, from which it was found that the dephosphorization efficiency increases as increasing the silicon content, meanwhile the increase rate becomes rapid when the silicon content is more than 10 mass pct. By analyzing the phase compositions of the dephosphorization slag of a high silicon Fe-Ni-Si melt, it was first found the dephosphorization products change with the silicon content. When Si contents are 10.5, 31.48, 34.71, and 43.15 mass pct, the de-P products are Ca2P2, Ca10+x Si12−2x P16, Ca4SiP4, and Ca10+x Si12−2x P16, as well as Ca4SiP4, respectively. The corresponding dephosphorization mechanism can be described as \( (2x)({\text{CaO}}) + (x + 2y)[{\text{Si}}] + 2z[{\text{P}}] = x({\text{SiO}}_{2} ) + 2({\text{Ca}}_{x} {\text{Si}}_{y} {\text{P}}_{z} ) \).

Similar content being viewed by others

References

P.X. Chen, S.J. Chu, and H.J. Wang: Proc. 13th Int. Ferroalloys Congress, Almaty, 2013, pp. 791–97.

H. Katayama, H. Kajioka, M. Inatomi, K. Harashima: Tetsu-To-Hagane, 1979, vol. 65, pp. 1167-75.

H. Katayama, H. Kajioka, K. Harashima, M. Inatomi: Trans. Iron Steel Inst. Jpn., 1979, vol. 19, pp. 635-43.

I. Tanabe: Japan patent 43-22501, (27 Sept 1968).

A. Eiji, D.J. Min, N. Sano: Testu-to-Hagane, 1988, vol. 74, pp.1931-38.

K. Kaneko, N. Sano, S. Takeuchi, S. Shiomi, Y. Matsushita: Testu-to-Hagane, 1977, vol. 63, pp. 2292-98.

S.K. Wei, R.M. Ni, K.M. Fang, C. Wu, and Y. Zhang: Iron Steel, 1985, vol. 20, pp. 67–73. (in Chinese).

B. Eisenmann, H. Jordan, and H.Schäfer: Mater. Res. Bull., 1982, vol. 17, pp. 95-99.

M. Hamon, J. Guyader, J. Lang: Rev. Chim. Miner., 1975, (12): 1-8.

M. Hamon, J. Guyader, J. Lang: Acta Crystallogr. B, 1975, vol. 31, pp. 445-49.

Q.Y. Han, X.D. Zhang, D. Chen, P.F. Wang: Metall. Trans. B, 1988, vol. 19B, pp. 617-22.

J.H. Shin, and J.H. Park: Proc. 13th Int. Ferroalloys Congress, Almaty, 2013, pp. 575–83.

P. Villars, A. Prince, H. Okamoto: Handbook of Ternary Alloy Phase Diagrams, ASM International, America, 1995: 7534.

I. Barin, transited by N.L. Chen: Thermochemical Data of Pure Substances, Science Press, Beijing, 2003. (in Chinese).

M. Y. Zhang, Q. A. Xiao, J. J. Lv: Ferro-alloys, 2006, vol 42, pp. 16-19. (in Chinese)

E. Simms: Elec. Furnace Conf. Proc., 1976, vol 34, pp.77-80.

M. A. Ryss, V. P. Zaiko: Steel in the USSR, 1973, vol 4, pp. 303-305.

K. Kume, K. Morita, T. Miki, N. Sano, 2000, vol. 40, pp. 561-566.

S. Tabbuchi, N. Sano: Metall. Trans. B, 1984, vol. 15B, pp. 351-56.

J. H. Shin, J.H. Park: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 1243-46.

B. Maramba, R.H. Eric: Miner. Eng., 2008, 21: 132-137.

Thanks are given to the financial supports from the National Natural Science Foundation of China (No. 51274030).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 30, 2015.

Rights and permissions

About this article

Cite this article

Chen, PX., Zhang, GH. & Chu, SJ. Study on Reaction Mechanism of Reducing Dephosphorization of Fe-Ni-Si Melt by CaO-CaF2 Slag. Metall Mater Trans B 47, 16–18 (2016). https://doi.org/10.1007/s11663-015-0472-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0472-1