Abstract

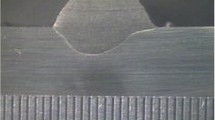

In the present study, artificial neural network modeling has been employed for predicting welding-induced angular distortions in autogenous butt-welded 304L stainless steel plates. The input data for the neural network have been obtained from a series of three-dimensional finite element simulations of TIG welding for a wide range of plate dimensions. Thermo-elasto-plastic analysis was carried out for 304L stainless steel plates during autogenous TIG welding employing double ellipsoidal heat source. The simulated thermal cycles were validated by measuring thermal cycles using thermocouples at predetermined positions, and the simulated distortion values were validated by measuring distortion using vertical height gauge for three cases. There was a good agreement between the model predictions and the measured values. Then, a multilayer feed-forward back propagation neural network has been developed using the numerically simulated data. Artificial neural network model developed in the present study predicted the angular distortion accurately.

Similar content being viewed by others

References

1. J.C. Wang, N. Ma, H. Murakawa, B. Teng, S. Yuan, Mater Des., 2011, 32, 4728- 4737.

2. D. Deng, H. Murakawa, W. Liang, Comp. Methods Appl. Mech. Eng. 2007, 196, 4613–4627.

3. J. Goldak, A. Chakravarti, M. Bibbi, Metall. Trans. B, 1984, 15B, 299-305.

4. H. Nishikawa, H. Serizawa, H. Murakawa, Quart. J. Jpn. Weld. Soc. 2006, 24 (2), 168–173.

5. Y. Ueda, and T. Yamakawa, Trans. Jpn. Weld. Soc. 1971, 12 (2), 90–100.

6. H. Murakawa, Y. Luo, and Y. Ueda, J. Soc. Nav. Architects Jpn. 1996, 180, 739–751.

Y. Luo, H. Murakawa, andY. Ueda, J. Soc. Nav. Architects Jpn. 1997, 182, 783–793

8. D. Deng, W. Liang, and H. Murakawa, J Mater Process Technol., 2007, 183, 219-225.

9. D. Deng, H. Murakawa, and W. Liang, J Mater Process Technol., 2008, 203, 252-266.

10. D. Deng, H. Murakawa, M. Shibahara, Comp Mater Sci., 2010, 48, 187-194.

11. H. Long, D. Gery b, A. Carlier, P.G. Maropoulos, Mater. Des., 2009, 30, 4126–4135.

12. Dean Deng, Mater. and Des., 2009, 30, 359–366.

M. Vasudevan, Mater. Manufac. Process., 2009, 24(2), pp. 209–18.

Pradip Ghanty, Samrat Paul, D. P. Mukherjee, M. Vasudevan, Nikhil R. Pal and A.K. Bhaduri, Sci. and Technol. of Weld. Join., 2007, 12(7), 649–58

Pradip Ghanty, M. Vasudevan, N. Chandrasekhar, Dipti Mukherjee, V. Maduraimuthu, N.R. Pal, A.K. Bhaduri, P. Bharat, and Baldev Raj, Sci. and Technol. of Weld. Join., 2008, 13 (4), 395–401

M. Vasudevan, M. Murugananth, A.K. Bhaduri, Baldev Raj and K. Prasad Rao, Sci. and Technol. of Weld. Join. 2004, 9 (2),109–20

M. Vasudevan, A.K. Bhaduri, Baldev Raj and K. Prasad Rao, Mater. Sci. Tech. 2007, 23 (4), 451–59

K. Manikya Kanti, and P. Srinivasa Rao, J. of Mater. Process. Tech., 2008, 200, 300–05.

19. S. Kumanan, and R. Kumar, Int J Adv Manuf Technol 2007, 31, 1083–91.

D. Nagesh, G. Datta, J Mater Process Techno 2002, 23, 303–12.

S. Chokkalingham, N. Chandrasekhar, M. Vasudevan, J Intell Manuf 2012, 23, 1995–2001.

M. Ahmadzadeh, A.HoseiniFard, B.Saranjam, H.R.Salimi, NDT&E International 2012, 52, 136–43.

Dong Hyuk Lim, In Ho Bae, Man Gyun Na, Jin Weon Kim, Nucl. Engi. Des. 2010, 240, 2555–64.

M.P. Lightfoot, G.J. Bruce, N.A. McPherson and K. Woods, Sci. Technol. Weld. Join., 2005, 10(2), 187–89.

M. Seyyedian Choobi, M. Haghpanahi and M. Sedighi, Comp Mater Sci, 2012, 62, 152–59

Z. Quan, Z. Gao, Q. Wang, X. Wen: SAE Int. J. Mater. Manuf., 2014-01-0755.

C. Liu, J.X. Zhang, C.B. Xue, Fusion Engg. Des., 2011, 86, 288–95.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted on November 13, 2014.

Rights and permissions

About this article

Cite this article

Narayanareddy, V.V., Chandrasekhar, N., Vasudevan, M. et al. Numerical Simulation and Artificial Neural Network Modeling for Predicting Welding-Induced Distortion in Butt-Welded 304L Stainless Steel Plates. Metall Mater Trans B 47, 702–713 (2016). https://doi.org/10.1007/s11663-015-0468-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0468-x