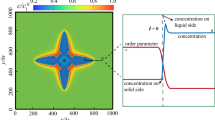

In this article, a front tracking (FT) model and a modified cellular automaton (MCA) model are presented and their capabilities in modeling the microstructure evolution during solidification of aluminum alloys are demonstrated. The FT model is first validated by comparison with the predictions of the Lipton–Glicksman–Kurz (LGK) model. Calculations of the steady-state dendritic tip growth velocity and equilibrium liquid composition as a function of melt undercooling for an Al-4 wt pct Cu alloy exhibit good agreement between the FT simulations and the LGK predictions. The FT model is also used to simulate the secondary dendrite arm spacing as a function of local solidification time. The simulated results agree well with the experimental data. The MCA model is applied to simulate dendritic and nondendritic microstructure evolution in semisolid processing of an Al-Si alloy. The effect of fluid flow on dendritic growth is also examined. The solute profiles in equiaxed dendritic solidification of a ternary aluminum alloy are simulated as a function of cooling rate and compared with the prediction of the Scheil model. The MCA model is extended to the multiphase system for the simulation of eutectic solidification. A particular emphasis is made on the quantitative aspects of simulations.

Similar content being viewed by others

References

W.J. Boettinger, S.R. Coriell, A.L. Greer, A. Karma, W. Kurz, M. Rappaz, and R. Trivedi: Acta Mater., 2000, vol. 48, pp. 43–70.

Stefanescu D.M. (1995) . Iron Steel Inst. Jpn. Int., 35: 637–50

H.W. Hesselbarth and I.R. Gobel: Acta Mater., 1991, vol. 39, pp. 2135– 43.

S.G. Brown and J.A. Spittle: Scripta Metall, 1992, vol. 27, pp. 1599– 1603.

M. Rappaz and C.-A. Gandin: Acta Metall. Mater., 1993, vol. 41, pp. 345–60.

C.-A. Gandin and M. Rappaz: Acta Metall. Mater., 1994, vol. 42, pp. 2233–46.

M. Rappaz, Ch.-A. Gandin, J.-L. Desbiolles, and Ph. Thevos: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 695–705.

Gandin C.-A., Rappaz M. (1997) . Acta Mater. 45: 2187–95

C.-A. Gandin, Ch.-A. Gandin, J.-L. Desbiolles, and Ph. Thevos: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 3153–65.

K.Y. Lee and C.P. Hong: Iron Steel Inst. Jpn. Int., 1997, vol. 37, pp. 38–46.

I.S. Cho and C.P. Hong: Iron Steel Inst. Jpn. Int., 1997, vol. 37, pp. 1098–1106.

Y.H. Chang, S.M. Lee, K.Y. Lee, and C.P. Hong: Iron Steel Inst. Jpn. Int., 1998, vol. 38, pp. 63–70.

L. Nastac: JOM, 1998, vol. 50(3), pp. 30–35.

K. Ravindran, S.G.R. Brown, and J.A. Spittle: Mater. Sci. Eng., A, 1999, vol. 269, pp. 90–97.

S.Y. Lee, S.M. Lee, and C.P. Hong: Iron Steel Inst. Jpn. Int., 2000, vol. 40, pp. 48–57.

H. Takatani, C.-A. Gandin, and M. Rappaz: Acta Mater., 2000, vol. 48, pp. 675–88.

U. Dilthey and V. Pavlik: in Modeling of Casting, Welding and Advanced Solidification Processes VIII, San Diego, CA, June 7–12, 1998, B.G. Thomas and C. Beckermann, eds., TMS, Warrendale, PA, 1998, pp. 589–96.

Nastac L. (1999) . Acta Mater. 47: 4253–62

W. Wang, P.D. Lee, and M. Mclean: Acta Mater., 2003, vol. 51, pp. 2971–87.

H.B. Dong and P.D. Lee: Acta Mater., 2005, vol. 53, pp. 659–68.

M.F. Zhu and C.P. Hong: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 436–45.

M.F. Zhu and C.P. Hong: Iron Steel Inst. Jpn. Int., 2002, vol. 42, pp. 520–26.

M.F. Zhu, J.M. Kim, and C.P. Hong: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 992–98.

M.F. Zhu, S.Y. Lee, and C.P. Hong: Phys. Rev. E, 2004, vol. 69, p. 061610.

M.F. Zhu, T. Dai, S.Y. Lee, and C.P. Hong: Sci. China Ser. E, 2005, vol. 48 (3), pp. 241–57.

M.F. Zhu and C.P. Hong: Phys. Rev. B: Condens. Matter Mater. Phys., 2002, vol. 66, p. 155428.

M.F. Zhu and C.P. Hong: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1555–63.

M.F. Zhu, W. Cao, S.-L. Chen, F.-Y. Xie, C.P. Hong, and Y.A. Chang: Trans. Nonferrous Met. Soc. China, 2006, in press.

L. Belteran-Sanchez and D.M. Stefanescu: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 367–82.

L. Belteran-Sanchez and D.M. Stefanescu: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2471–85.

M.F. Zhu and D.M. Stefanescu: Modeling of Casting, Welding and Advanced Solidification Processes XI, Club Med, Opio, France, May 28–June 2, 2006, C.-A. Gandin, and M. Bellet, eds., TMS, Warrendale, PA, pp. 473–80.

J. Lipton, M.E. Glicksman, and W. Kurz: Mater. Sci. Eng., 1984, vol. 65, pp. 57–63.

M.C. Flemings, T.Z. Kattamis, and B.P. Bardes: AFS Trans., 1991, vol. 99, pp. 501–06.

K. Watanabe, M. Itamura, J.M. Kim, and C.P. Hong: Die Mould Technol., 2005, vol. 20 (5), pp. 33–36.

Flemings M.C., Young K.P. (1978) Rheocasting, Yearbook of Science and Technology. McGraw-Hill, New York, NY

UBE Industries Ltd.: European Patent No. EP0 745 694 A1, Dec. 1996.

C.P. Hong: JP Patent No. 3,549,054, 2003.

C.P. Hong: U.S. Patent No. 6 ,942,009 (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation made in the symposium ”Simulation of Aluminum Shape Casting Processing: From Design to Mechanical Properties,” which occurred March 12–16, 2006, during the TMS Spring Meeting in San Antonio, Texas, under the auspices of the Computational Materials Science and Engineering Committee, the Process Modeling, Analysis and Control Committee, the Solidification Committee, the Mechanical Behavior of Materials Committee, and the Light Metal Division/Aluminum Committee.

Rights and permissions

About this article

Cite this article

Zhu, M.F., Hong, C.P., Stefanescu, D.M. et al. Computational Modeling of Microstructure Evolution in Solidification of Aluminum Alloys. Metall Mater Trans B 38, 517–524 (2007). https://doi.org/10.1007/s11663-007-9052-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-007-9052-3