Abstract

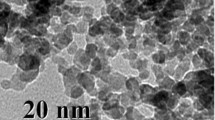

An unprecedented uniform distribution of nano-dispersoids in aluminum-alumina bulk nanocomposite and enhancement in mechanical properties were achieved through a novel ultrasonic casting technique involving two-step ultrasonication. Ultrasonic casting can be classified into two types: (a) contact type, in which the sonicating probe is in direct contact with the liquid melt during ultrasonication and (b) non-contact type, in which the ultrasonic waves reach the liquid melt through the mold wall. Each of the processes has certain disadvantages, and the present study aims at eliminating the primary disadvantages of both the processes, through a novel two-step ultrasonic casting technique. The significant improvement in distribution was possibly due to the cavitation in the mold, leading to the elimination of non-uniformity in the cooling rate at the mesoscopic scale. The improvement in mechanical properties is explained through microstructure analysis in correlation with EBSD analysis, TEM analysis, hardness test, and tensile test. The yield strength of the nanocomposite produced by the two-step process was ~38 pct higher than that produced by non-contact and contact methods.

Similar content being viewed by others

References

S. Mula, P. Padhi, S.C. Panigrahi, S.K. Pabi, and S. Ghosh: Mater. Res. Bull., 2009, vol. 44, pp. 1154–60.

S. Mula, S.K. Pabi, C.C. Koch, P. Padhi, and S. Ghosh: Mater. Sci. Eng. A, 2012, vol. 558, pp. 485–91.

P. Padhi, K.N. Kumar, S. Ghosh, H.M. Vishwanatha, S.C. Panigrahi, and S. Ghosh: Mater. Manuf. Process., 2015, vol. 0, pp. 1–8. 10.1080/10426914.2015.1004707

R.S. Rana, R. Purohit, and S. Das: Int. J. Sci. Eng. Res., 2012, vol. 3, pp. 1–16.

L.Y. Chen, J.Y. Peng, J.Q. Xu, H. Choi, and X.C. Li: Scr. Mater., 2013, vol. 69, pp. 634–37.

L.Y. Chen, D. Weiss, J. Morrow, J.Q. Xu, and X.C. Li: Manuf. Lett., 2013, vol. 1, pp. 62–65.

J. Hashim, L. Looney and M.S.J. Hashmi: J. Mater. Process. Technol., 1999, vol. 92–3, pp. 1–7.

S.A. Sajjadi, H.R. Ezatpour, and H. Beygi: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8765–71.

C. Suryanarayana, E. Ivanov, and V. Boldyrev: Mater. Sci. Eng. A, 2001, vol. 304–306, pp. 151–58.

H. Gleiter: Acta Mater., 2000, vol. 48, pp. 1–29.

J.Q. Xu, L.Y. Chen, H. Choi, and X.C. Li: J. Phys. Condens. Matter., 2012, vol. 24, pp. 255304–14.

G.I. Eskin: Adv. Perform. Mater., 1997, vol. 1, pp. 223–32.

M. De Cicco, H. Konishi, G. Cao, H.S. Choi, L.S. Turng, J.H. Perepezko, S. Kou, R. Lakes, and X. Li: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 3038–45.

S.A. Vorozhtsov, D.G. Eskin, J. Tamayo, A.B. Vorozhtsov, V. V Promakhov, A.A. Averin, and A.P. Khrustalyov: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 2870–75.

G. Cao, J. Kobliska, H. Konishi, and X. Li: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 880–86.

H. Choi, M. Jones, H. Konishi, and X. Li: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 738–46.

Y. Yang, J. Lan, and X. Li: Mater. Sci. Eng. A, 2004, vol. 380, pp. 378–83.

N. Srivastavaa, and G.P. Chaudhari: Mater. Sci. Eng. A, 2016, vol. 651, pp. 241–47.

S. Kandemir, D.P. Weston, and H. V. Atkinson: Key Eng. Mater., 2012, vol. 504–506, pp. 339–44.

H. Ribes, R. Da Silva, M. Suéry, and T. Bretheau: Mater. Sci. Technol., 1990, vol. 6, pp. 621–28.

L.-Y. Chen, J.-Q. Xu, and X.-C. Li: Mater. Res. Lett., 2015, vol. 3, pp. 43–49.

L.-Y. Chen, J.-Q. Xu, H. Choi, M. Pozuelo, X. Ma, S. Bhowmick, J.-M. Yang, S. Mathaudhu, and X.-C. Li: Nature, 2015, vol. 528, pp. 539–43.

G.I. Eskin: Ultrason. Sonochem., 2001, vol. 8, pp. 319–25.

G.I. Eskin, and D.G. Eskin: Ultrason. Sonochem., 2003, vol. 10, pp. 297–301.

T. Hielscher: ENS’ 05 Paris, Paris, France, 2005, pp. 1–6.

A. Ramirez, M. Qian, B. Davis, T. Wilks, and D.H. StJohn: Scr. Mater., 2008, vol. 59, pp. 19–22.

Y.M. Youssef, R.J. Dashwood, and P.D. Lee: Compos. Part A, 2005, vol. 36A, pp. 747-63.

S. Sen, B.K. Dhindaw, D.M. Stefanescu, A. Catalina, and P.A. Curreri: J. Cryst. Growth, 1997, vol. 173, pp. 574–84.

F.R. Juretzko, B.K. Dhindaw, D.M. Stefanescu, S. Sen, and P.A. Curreri: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 1691–96.

D.M. Stefanescu, F.R. Juretzko, B.K. Dhindaw, A. Catalina, and S. Sen: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 1697–706.

J.B. Ferguson, G. Kaptay, B.F. Schultz, P.K. Rohatgi, K. Cho, and C.S. Kim: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 4635–45.

George E. Dieter: Mechanical Metallurgy, 2nd ed., McGraw-Hill book Co., New York, 1988.

Acknowledgments

This work was supported by the National Institute of Ocean Technology, Chennai, Ministry of Earth Sciences, New Delhi, INDIA, and the work was carried out at Indian Institute of Technology Kharagpur, INDIA.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 3, 2016.

Rights and permissions

About this article

Cite this article

Vishwanatha, H.M., Eravelly, J., Kumar, C.S. et al. Microstructure and Mechanical Properties of Aluminum-Alumina Bulk Nanocomposite Produced by a Novel Two-Step Ultrasonic Casting Technique. Metall Mater Trans A 47, 5630–5640 (2016). https://doi.org/10.1007/s11661-016-3740-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3740-z