Abstract

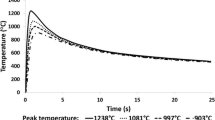

NUCu-140 is a ferritic copper precipitation-strengthened steel that is a candidate material for use in many naval and structural applications. Previous work has shown that the heat-affected zone (HAZ) and fusion zone (FZ) of NUCu-140 exhibit softening that is due to dissolution of the copper-rich precipitates. This study aims to recover the FZ and HAZ strength by re-precipitation of the copper-rich precipitates through either multiple weld passes or an isothermal post-weld heat treatment (PWHT). The potential use of multiple thermal cycles was investigated with HAZ simulations using a Gleeble thermo-mechanical simulator. The HAZ simulations represented two weld thermal cycles with different combinations of peak temperatures during the initial and secondary weld passes. To investigate the potential for a PWHT for strength recovery, gas tungsten arc weld samples were isothermally heated for various times and temperatures. Microhardness measurements revealed no strength recovery in the multipass HAZ samples. The time-dependent precipitate characteristics were modeled under the HAZ thermal cycle conditions, and the results showed that the lack of strength recovery could be attributed to insufficient time for re-precipitation during the secondary weld pass. Conversely, full strength recovery in the HAZ was observed in the isothermally heat treated samples. Atom probe tomography analysis correlated this strength recovery to re-precipitation of the copper-rich precipitates during the isothermal PWHT.

Similar content being viewed by others

References

S. Vaynman, D. Isheim, R. P. Kolli, S. P. Bhat, D. N. Seidman, and M. E. Fine: Metall. Mater. Trans. A, 2008, vol. 39, pp. 363–373.

R. P. Kolli, R. M. Wojes, S. Zaucha, and D. N. Seidman: Int. J. Mater. Res., 2008, vol. 99, pp. 513–527.

R. P. Kolli and D. N. Seidman: Acta Mater., 2008, vol. 56, pp. 2073–2088.

D. Isheim, R. P. Kolli, M. E. Fine, and D. N. Seidman: Scr. Mater., 2006, vol. 55, pp. 35–40.

D. Isheim, M. S. Gagliano, M. E. Fine, and D. N. Seidman: Acta Mater., 2006, vol. 54, pp. 841–849.

D. Isheim, A. H. Hunter, X. J. Zhang, and D. N. Seidman: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 3046-3059.

J. Blackburn: Base Materials for Critical Applications—Requirements for Low Alloy Steel Plate, Forgings, Castings, Shapes, Bars, and Heads of HY-80/100/130 and HSLA-80/100, Naval Sea Systems Command, December 2012.

H.R. Castner and C.L. Null: Weld. J., 1998, vol. 77, pp. 223s–231s.

J. D. Farren, A. H. Hunter, J. N. Dupont, D. N. Seidman, C. V. Robino, and E. Kozeschnik: Metall. Mater. Trans. A, 2012, vol. 43, pp. 4155–4170.

R. Katenhauser: Source Book on Stainless Steel, ASM International, Materials Park, OH, 1976, pp. 229-312.

F.G. Harkins: Weld. Res. Counc. Bull., 1965, vol. 103.

G. E. Linnert: Weld. J., 1957, vol. 36, pp. 9–27.

K. Bhaduri, S. Venkadesen: Steel Res., 1989, vol. 60, pp. 509–513.

G. O. Rading, M. Shamsuzzoha, and J. T. Berry: Weld. J., 1998, vol. 77, p. 411s–416s.

G. E. Metzger: Weld. J., 1967, vol. 46, p. 457s–469s.

S.D. Dumolt, D.E. Laughlin, and J.C. Williams: 1st Inter. Aluminum Welding Conf., Cleveland, OH, April 7–8, Welding Research Council, New York, 1981, pp. 115–21.

X. Yu, J. L. Caron, S. S. Babu, J. C. Lippold, D. Isheim, and D. N. Seidman: Metall. Mater. Trans. A, 2011, vol. 42, pp. 3669–3679.

I. Holzer and E. Kozeschnik: Mater. Sci. Eng., A, 2010, vol. 527, pp. 3546–3551.

E. Kozeschnik: Scr. Mater., 2008, vol. 59, pp. 1018–1021.

P.W. Fuerschbach, G.R. Eisler, and R.J. Steele: 5th Proc. Int. Conf. Trends Weld. Res., 1999, pp. 488–91.

P.W. Feurschbach and G.R. Eisler: 6th Proc. Int. Conf. Trends Weld. Res., 2002, pp. 782–86.

E. A. Marquis and J. M. Hyde: Mater. Sci. Eng., R, 2010, vol. 69, pp. 37-62.

D. Vaumousse, A. Cerezo, and P. J. Warren: Ultramicroscopy, 2003, vol. 95, pp. 215-221.

R.P. Kolli and D.N. Seidman: Microsc. Microanal., 2007, vol. 13, pp. 272-284.

O. C. Hellman, J. A. Vanderbroucke, J. Rüsing, D. Isheim, and D. N. Seidman: Microsc. Microanal., 2000, vol. 6, pp. 437-444.

M. D. Mulholland and D. N. Seidman: Scr. Mater., 2009, vol. 60, pp. 992–995.

M. Kapoor, D. Isheim, G. Ghosh, S. Vaynman, M. E. Fine, Y. W. Chung: Acta Mater., 2014, vol. 73, pp. 56-74.

Y. R. Wen, Y. P. Hirata, Y. Zhang, T. Fugita, T. Furuhara, and M. W. Chen: Acta Mater., 2013, vol. 61, pp. 7726-7740.

R.P. Kolli, Z. Mao, D.N. Seidman, and D.T. Keane: Appl. Phys. Lett., 2007, vol. 91, pp. 241903-1–241903-3.

F. Vurpillot, A. Bostel, and D. Blavette: Appl. Phys. Lett., 2000, vol. 76, pp. 3127-3129.

J. L. Caron, X. Yu, S. S. Babu, J. C. Lippold, D. Isheim, and D. N. Seidman: Acta Mater., 2010, vol. 58, pp. 5569–5609.

Acknowledgments

The authors gratefully acknowledge financial support of this research by the Office of Naval Research through Grant Number N00014-12-1-0475 and useful discussions with the Program Manager, Dr. William Mullins, of the Office of Naval Research. LEAP measurements were performed at the Northwestern University Center for Atom-Probe Tomography (NUCAPT). The LEAP tomography system was purchased and upgraded with funding from NSF-MRI Grant DMR-0420532 and ONR-DURIP Grants N00014-0400798, N00014-0610539, and N00014-0910781.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 23, 2015.

Rights and permissions

About this article

Cite this article

Bono, J.T., DuPont, J.N., Jain, D. et al. Investigation of Strength Recovery in Welds of NUCu-140 Steel Through Multipass Welding and Isothermal Post-Weld Heat Treatments. Metall Mater Trans A 46, 5158–5170 (2015). https://doi.org/10.1007/s11661-015-3087-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3087-x