Abstract

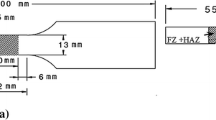

Laser-arc hybrid welding with Cu3Si filler wire was employed to join dissimilar Ti6Al4V titanium alloy and AISI316 stainless steel (316SS). The effects of welding parameters on bead shape, microstructure, mechanical properties, and fracture behavior were investigated in detail. The results show that cross-weld tensile strength of the joints is up to 212 MPa. In the joint, obvious nonuniformity of the microstructure is found in the fusion zone (FZ) and at the interfaces from the top to the bottom, which could be improved by increasing heat input. For the homogeneous joint, the FZ is characterized by Fe67−x Si x Ti33 dendrites spreading on α-Cu matrix, and the two interfaces of 316SS/FZ and FZ/Ti6Al4V are characterized by a bamboo-like 316SS layer and a CuTi2 layer, respectively. All the tensile samples fractured in the hardest CuTi2 layer at Ti6Al4V side of the joints. The fracture surface is characterized by river pattern revealing brittle cleavage fracture. The bead formation mechanisms were discussed according to the melt flow and the thermodynamic calculation.

Similar content being viewed by others

References

AEL Refaey, W. Tillmann: Weld. J., 2008. 87, 113–18.

G. Thirunavukarasu, S. Kundu, B. Mishra, and S. Chatterjee: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 2067–77.

AEL Refaey, W. Tillmann: J. Mater. Process. Technol, 2009. 209, 2746–52.

M. Ghosh, S. Kundu, S. Chatterjee, and B. Mishra: Metall. Mater. Trans. A, 2005, vol. 36A, pp.1891–99.

S. Kundu, M. Ghosh, A. Laik, K. Bhanumuthy, G.B. Kale, and S. Chatterjee: Mater. Sci. Eng. A, 2005, vol. 407, pp. 154–60.

E. Atasoy, and N. Kahraman: Mater. Charact., 2008, vol. 59, pp. 1481–89.

S. Kundu, and S. Chatterjee: Mater. Charact., 2008, vol. 59, pp. 631–37.

S. Chen, J. Huang, K. Ma, X. Zhao, and A. Vivek: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 3064–73.

P. He, H. Yue, and J.H. Zhan: Mater. Sci. Eng. A, 2008, vol. 486, pp. 171–76.

M. Gao, S.W. Mei, Z.M. Wang, X.Y. Li, and X.Y. Zeng: Sci. Technol. Weld. Join., 2012, vol. 17, pp. 269–76.

T. Wang, B.G. Zhang, G.Q. Chen, J.C. Feng, and Q. Tang: Trans. Nonferrous Met. Soc. Chin., 2010, vol. 20, pp. 1829–34.

H.C. Dey, M. Ashfaq, A.K. Bhaduri, and K. Prasad Rao: J. Mater. Process. Tech., 2009, vol. 209, pp. 5862–70.

M FazelNajafabadi, SF KashaniBozorg, A. ZareiHanzaki: Mater. Des. 2010. 31, 4800-07.

L.Q. Li, C.W. Tan, Y.B. Chen, W. Guo, and X.B. Hu: Metall. Mater. Trans. A, 2012, vol. 43A, pp.4740–54.

M. Gao, Z.M. Wang, X.Y. Li, and X.Y. Zeng: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 163–72.

S.H. Chen, L.Q Li, Y.B. Chen, and J. Dai: Mater. Des., 2011, vol. 32, pp. 4408–16.

M. Gao, C. Chen, Y. Gu, and X.Y. Zeng: Materials, 2014, vol. 7, pp.1590–1602.

S. Chen, J. Huang, K. Ma, H. Zhang, and X. Zhao: Metall. Mater. Trans. A, 2014, vol. 44A, pp. 3690–96.

S.W. Mei, M. Gao, J. Yan, C. Zhang, G. Li, and X.Y. Zeng: Sci. Technol. Weld. Join., 2013, vol. 18, pp. 293–300.

C. Bagger, and F. O. Olsen: J. Laser Appl., 2005, vol. 17, pp. 2–14.

L.M. Liu, H.Y. Wang, and Z.D. Zhang: Scripta Mater., 2007, vol. 56, pp. 473–76.

X.D. Qi, and G. Song: Mater. Des., 2010, vol. 31, pp. 605–09.

V. Raghvan: J. Phase Equilib. Diff., 2002, vol. 23, pp. 172–74.

J.A. Van Beek, A.A. Kodentsov, and F.J. Van Loo: J. Alloys Compd., 1995, vol. 217, pp. 97–103.

G. Effenberg and S. Ilyenko: in Light Metal Ternary Systems: Phase Diagrams, Crystallographic and Thermodynamic Data, 1st ed., Materials Science International Team MIST, Stuttgart, Germany, 2006, vol. 11A4, pp. 284–98.

V. Raghvan: J. Phase Equilib. Diff., 2009, vol. 30, pp. 393–96.

F. Weitzer, J.C. Schuster, M. Naka, F. Stein, and M. Palm: Intermetallics, 2008, vol 16, pp. 273–82.

M. Gao, S.W. Mei, Z.M. Wang, X.Y. Li, and X.Y. Zeng: J. Mater. Process. Technol., 2012, vol. 212, pp. 1338–46.

J. Zhou, and H.L. Tsai: Int. J. Heat. Mass Trans., 2008, vol. 51, pp. 4353–66.

A.R. Miedema, P.F. De Chatel, and F.R. De Boen: Physica B, 1980, vol. 100, pp. 1–28.

R.H. Davies, A. T. Dinsdale, and J.A. Gisby: CALPHAD, 2002, vol. 26, pp. 229–71.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 27, 2014.

Rights and permissions

About this article

Cite this article

Gao, M., Chen, C., Wang, L. et al. Laser-Arc Hybrid Welding of Dissimilar Titanium Alloy and Stainless Steel Using Copper Wire. Metall Mater Trans A 46, 2007–2020 (2015). https://doi.org/10.1007/s11661-015-2798-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2798-3