Abstract

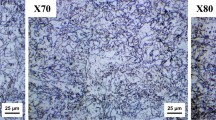

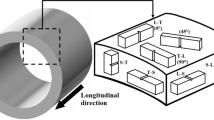

The effects of microstructure on tensile, Charpy impact, and crack tip opening displacement (CTOD) properties of two API X80 pipeline steels were investigated in this study. Two API X80 pipeline steels consisting of acicular ferrite and granular bainite, and a small amount of hard phases such as martensite and secondary phases have elongated grains along the rolling direction, so that they show different mechanical properties as the specimens’ directions change. The 90 deg specimens have high tensile strength due to the low stress concentration on the fine hard phases and the high loads for the deformation of the elongated grains. In contrast, the 30 deg specimens have less elongated grains and larger hard phases such as martensite, with the size of about 3 μm, than the 90 deg specimens. Hence, the 30 deg specimens have low tensile strength because of the high stress concentration on the large hard phases and the low loads to deform grains. In the 90 deg specimen, brittle crack propagation surfaces are even since cracks propagate in a straight line along the elongated grain structure. In the 30 deg specimen, however, brittle crack propagation surfaces are uneven, and secondary cracks are observed, because of the zigzag brittle crack propagation path. In the CTOD properties, the 90 deg specimens have maximum forces of higher magnitude than the 30 deg specimens, because of the elongated grain structure. However, CTODs of the 90 deg specimens are lower than those of the 30 deg specimens because of the low plastic deformation areas by the elongated grains in the 90 deg specimens.

Similar content being viewed by others

References

R. Deny: Pipeline Technology, vol. I & II, Elsevier, Amsterdam, Netherlands, 2000.

D.P. Fairchild, M.L. Macia, S.D. Papka, C.W. Petersen, J.H. Stevens, S.T. Barbas, N.V. Bangaru, J.Y. Koo, and M.J. Luton: Proceedings of the International Pipe Dreamer’s Conference, Scientific Surveys, Ltd., Yokohama, Japan, 2002, pp. 307-21.

K.T. Corbett, R.R. Bowen, and C.W. Petersen: Int. J. Offshore Polar Eng., 2004, vol. 14, pp. 75-80.

API (1996) API Recommended Practice 5L3. API, Washington, DC.

G. Mannucci and D. Harris: Fracture Properties of API X100 Gas Pipeline Steels, Final Report, European Commission, 2002, pp. 1-128.

B. Mintz, W.B. Morrison, P.I. Welch, and G.J. Davies: (1978) In: G. Gottstein, K. Lucke (Eds.), Texture of Materials, vol 2. Springer, Berlin, pp. 465–74.

K. Kim and J.-H. Bae: 7th International Pipeline Conference, vol. 3, ASME, New York, 2008, pp. 167–73.

M.K. Gräf, H.G. Hillenbrand, C.J. Heckmann, and K.A. Niederhoff: Proceedings of 13th International Offshore and Polar Engineering Conference, Honolulu, Hawaii, 2003, pp. 97-104.

J.Y. Koo, M.J. Luton, N.V. Bangaru, R.A. Petkovic, D.P. Fairchild, C.W. Petersen, H. Asahi, T. Hara, Y. Terada, M. Sugiyama, H. Tamehiro, Y. Komizo, S. Okaguchi, M. Hamada, A. Yamamoto, and I. Takeuchi: Proceedings of 13th International Offshore and Polar Engineering Conference, Honolulu, Hawaii, 2003, pp.10-18.

ASTM Standard E1290: Standard Test Method for Crack-Tip Opening Displacement (CTOD) Fracture Toughness Measurement, ASTM, West Conshohocken, PA, 2008.

ASTM Standard E23: Standard Test Method for Notched Bar Impact Testing of Metallic Materials, ASTM, West Conshohocken, PA, 2007.

J.-I. Jang, Y. Choi, J.-S. Lee, Y.-H. Lee, D. Kwon, M. Dao, and R. Kania: Int. J. Fract., 2005, vol. 131, pp. 15–34.

I. Tamura, H. Sekine, T. Tanaka, and C. Ouchi: Thermomechanical Processing of High-strength Low-alloy Steels, Butterworth & Co. Ltd., London, UK, 1988, pp. 80-100.

W. Oldfield: Fitting Impact Test Data—A Statistical Procedure, ASTM Standardizations News, 1975, p. 24.

T. Araki: Atlas for Bainitic Microstructures, ISIJ, Tokyo, Japan, 1992, pp. 1-100.

G. Krauss and S.W. Thompson: ISIJ Int., 1995, vol. 35, pp. 937-45.

S.W. Thompson, D.J. Colvin, and G. Krauss: Metall. Trans. A, 1990, vol. 21A, pp. 1493-1507.

H.K.D.H. Bhadeshia: Mater. Sci. Eng. A, 2004, vol. A378, pp. 34-39.

Y.M. Kim, S.K. Kim, Y.J. Lim, and N.J. Kim: ISIJ Int. 2002, vol. 42, pp. 1571–77.

G.E. Dieter: Mechanical Metallurgy, McGraw-Hill Book Co., New York, NY, 1988.

S.H. Mousavi Anijdan and S. Yue: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 1140-62.

W. Yan, P. Hu, L. Deng, W. Wang, W. Sha, Y. Shan, and K. Yang: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 1921-33.

R. Punch, M. Strangwood, and C. Davis: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4622-32.

M.S. Joo, D.W Seo, J.B. Bae, and H.K.D.H. Bhadeshia, Mater. Sci. Eng. A, 2012, vol. A546, pp. 314-22.

M. Jafari, Y. Kimura, and K. Tsuzaki: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 2453-64.

D. Liu, Q. Li, and T. Emi: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 1349-61.

Acknowledgments

This study was financed by Alexander von Humboldt Foundation, and was supported by POSCO under a contract No. 2007Y202, and the Ministry of Knowledge Economy under a grant No. 100400-25. The author would like to thank Prof. Sunghak Lee of Pohang University of Science and Technology, and Drs. Jin-ho Bae and Kisoo Kim of POSCO for their help in the processing of the pipeline steels and experimental analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 7, 2012.

Rights and permissions

About this article

Cite this article

Shin, S.Y. Effects of Microstructure on Tensile, Charpy Impact, and Crack Tip Opening Displacement Properties of Two API X80 Pipeline Steels. Metall Mater Trans A 44, 2613–2624 (2013). https://doi.org/10.1007/s11661-013-1613-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1613-2