Abstract

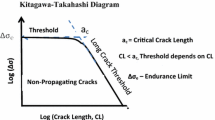

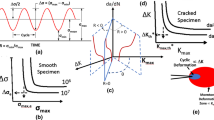

Kitagawa-Takahashi diagram that is modified for fatigue is now extended to the subcritical crack growth behavior under stress-corrosion crack growth. The analogy with the fatigue helps us to identify several regimes of interest from both the point of understanding of the material behavior as well as quantification of the failure process for structural design of components that are subjected to stress-corrosion and corrosion fatigue crack growths and failure. In particular, the diagram provides a means of defining the mechanical equivalent of chemical stress concentration factor and the chemical crack-tip driving forces to crack growth or its arrest. In addition, threshold stresses, crack arrest, and nonpropagating crack growth conditions can be defined, which help in developing sound design methodology against stress corrosion and corrosion fatigue. Chemical crack driving forces under corrosion fatigue can be similarly defined using the inert behavior as a reference.

Similar content being viewed by others

References

J.R. Rice: Proc. 1st Inter. Con. Fracture, Sendai, 1965, T. Yokobori, T. Kawasaki, and J.L. Swedlow, eds., Japan Society for Strength and Fracture of Materials, Tokyo, 1966, vol. 1, pp. 309–40.

J.P. Hirth and J. Lothe: Theory of Dislocations, 2nd ed., Wiley, New York, 1982.

G.R. Irwin: J. Appl. Mech., 1957, vol. 24, pp. 361–64.

H. Neuber: J. Appl. Mech., 1961, vol. 23, pp. 544–50.

K. Tanaka, Y. Nakai, and M. Yamashita: Int. J. Fatigue, 1981, vol. 17, pp. 519–33.

A.K. Vasudevan and K. Sadananda: Metall. Mater. Trans., 2011, vol. 42A, pp. 366–404.

C. Laird and G.C. Smith: Philos. Mag., 1962, vol. 8, pp. 847–57.

K. Sadananda and P. Shahinian: Int. J. Fract., 1977, vol. 13, pp. 585–94.

N.E. Dowling: Mechanical Behavior of Materials; Engineering Methods for Deformation Fracture and Fatigue, 3rd ed., Prentice-Hall, Upper Saddle River, NJ, 2007.

K. Sadananda and A.K. Vasudevan: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 279–95.

S.P. Lynch: in Hydrogen Effects in Materials Behavior and Corrosion Interactions Deformations, N.R. Moody, A.W. Thompson, R.E. Ricker, G.W. Was, and R.H. Jones, eds., TMS, Warrendale, PA, 2003, pp. 449–66.

R.P. Gangloff: in Comprehensive Structural Integrity, I. Milne, R.O. Ritchie, and B. Karihaloo, eds., Elsevier, New York, NY, 2003, vol. 6.

R.A. Oriani: in Stress Corrosion Cracking and Hydrogen Embrittlement of Iron Base Alloys, R.W. Stahle, J. Hochman, R. McCright, and J. Slater, eds., NACE-5, National Association of Engineers, Houston, TX, 1971, pp. 32–50.

W.W. Gerberich and S. Chen: in Environment Induced Cracking of Metals, R.P. Gangloff and H.B. Ives, eds., NACE, Houston, TX, 1990, pp. 167–86.

E. Protopopoff and P. Marcus: in Corrosion Mechanisms in Theory and Practice, P. Marcus, ed., Marcel Dekker, Basil, 2002, pp. 53–96.

M.H. Kamdar: in Treatise on Materials Science and Technology, C.L. Briant and S.K. Benerji, eds., Academic Press, New York, NY, 1983, vol. 25, pp. 361–459.

H. Kitagawa and S. Takahashi: Proceedings of the Second 954 International Conference on Mechanical Behavior of Materials. ASM, Metals Park, OH, 1976, pp. 627–31.

R.P. Gangloff: Metall. Trans. A, 1985, vol. 16A, pp. 953–69.

E. Glickman: Interface Sci., 2003, vol. 11, p. 451.

Y. Hirose and T. Mura: Eng. Fract. Mech., 1984, vol. 19, pp. 1057–67.

K. Sadananda, S. Sarkar, D. Kujawski, and A.K. Vasudevan: Int. J. Fatigue, 2009, vol. 31, pp. 1648–59.

A.K. Vasudevan and K. Sadananda: Int. J. Fatigue, 2009, vol. 31, pp. 1696–1708.

Acknowledgments

The author acknowledges the helpful discussions with Dr. A. K. Vasudevan of ONR. The research is supported by ONR under the contract N00014-10c-0359 with Dr. Vasudevan as Technical Monitor.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 26, 2012.

Rights and permissions

About this article

Cite this article

Sadananda, K. Failure Diagram and Chemical Driving Forces for Subcritical Crack Growth. Metall Mater Trans A 44, 1190–1199 (2013). https://doi.org/10.1007/s11661-012-1469-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1469-x