Abstract

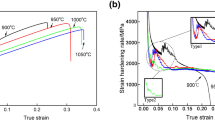

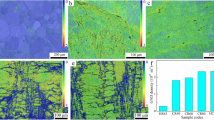

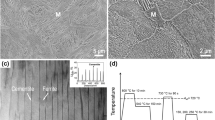

The effect of quenching, tempering, cold-rolling, and aging treatments, which produce different dislocation substructures and different carbide distributions, on the creep-deformation behavior is investigated for a tempered martensitic 9Cr-1W steel at 873 K, mainly. The creep rate vs time curves indicate transient creep, where the creep rate decreases with time, and accelerating creep, where the creep rate increases with time. The minimum creep rate is closely correlated with the onset time of acceleration creep and is inversely proportional to the duration of the transient creep region. The onset of acceleration creep shifts to shorter times for the specimens subjected to the quenching, 20-hour tempering (long-term tempering) at 1023 K, and cold-rolling treatments than that for the specimen subjected to the standard quenching and tempering (QT) treatment. The onset of acceleration creep is closely correlated with the migration of lath or subgrain boundaries, causing the coarsening of laths or subgrains. Dislocation cells produced by cold rolling are free of M23C6 carbides. The migration and recovery of dislocation cells significantly promote the onset of acceleration creep. The preferential distribution of M23C6 carbides along lath boundaries is effective for the retardation of the onset of acceleration creep for up to longer times by the stabilization of lath boundaries. In the acceleration creep region, after reaching a minimum creep rate, the logarithm of the creep rate increases linearly with strain for a wide range of strains. The time to rupture (tr) is inversely proportional to the minimum creep rate \((\dot \varepsilon _{\min } )\) times the acceleration of the creep rate (d ln \(\dot \varepsilon \)/dε) in the acceleration creep region, but is not proportional to only the minimum creep rate, as given by

This equation is derived on the basis of the exponential function of strain in the acceleration creep region.

Similar content being viewed by others

References

M. Staubli, K.H. Mayer, T.U. Kern, R.W. Vanstone, R. Hanus, J. Stief, and K.H. Schonfeld: Proc. 3rd EPRI Conf. on Advances in Materials Technology for Fossil Power Plants, The Institute of Materials, London, United Kingdom, 2001, pp. 15–32.

W.P. Parks, P. Hoffman, M.A. Karnitz, and I.G. Wright: Proc. 6th Liege Conf. on Materials for Advanced Power Engineering, Forschungszentrum Jülich GmbH, Jülich, Germany, 1998, pp. 1789–1805.

F. Abe, M. Igarashi, S. Wanikawa, M. Tabuchi, T. Itagaki, K. Kimura, and K. Yamaguchi: Proc. 3rd EPRI Conf. on Advances in Materials Technology for Fossil Power Plants, The Institute of Materials, London, United Kingdom, 2001, pp. 79–88.

F. Abe and T. Noda: Encyclopedia of Materials: Science and Technology, K.H.J. Buschow, R.W. Cahn, M.C. Flemings, B. Ilschner, E.J. Kramer, and S. Mahajan, eds., Elsevier Science, Amsterdam-New York-Oxford-Paris-Shannon-Tokyo, 2001, pp. 3418–22.

F. Masuyama: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 612–25.

K. Maruyama, K. Sawada, and J. Koike: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 641–53.

B.F. Dyson and M. McLean: Iron Steel Inst. Jpn. Int., 1990, vol. 30, pp. 802–11.

B.F. Dyson and M. McLean: Acta Metall., 1983, vol. 31, pp. 17–27.

F. Abe, H. Araki, and T. Noda: Metall. Trans. A, 1991, vol. 22A, pp. 2225–35.

F. Abe, S. Nakazawa, H. Araki, and T. Noda: Metall. Trans. A, 1992, vol. 23A, pp. 469–77.

F. Abe and S. Nakazawa: Metall. Trans. A, 1992, vol. 23A, pp. 3025–34.

F. Abe: unpublished research.

F. Abe and S. Nakazawa: Metall. Trans. A, 1992, vol. 23A, pp. 3025–34.

F. Abe: Mater. Sci. Eng., 1997, vols. A234–A236, pp. 1045–48.

M. Prager: Pressure Vessel Piping, 1994, vol. 288, pp. 401–21.

R. Woo, R. Sandstrom, and J. Storesund: Mater. High Temp., 1994, vol. 12, pp. 277–83.

S. Straub, M. Meier, J. Ostermann, and W. Blum: VGB Kraftwerkstechnik, 1993, vol. 73, pp. 646–53.

F. Abe: Mater. Sci. Eng., 2001, vols. A319–A321, pp. 770–73.

R.W. Evans and B. Wilshire: Creep of Metals and Alloys, The Institute of Metals, London, 1985, pp. 9–21.

R.D. Doherty: Physical Metallurgy, 3rd ed., R.W. Cahn and P. Haasen, eds., North-Holland Physics Publishing, Amsterdam 1983, pp. 987–96.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Abe, F. Effect of quenching, tempering, and cold rolling on creep deformation behavior of a tempered martensitic 9Cr-1W steel. Metall Mater Trans A 34, 913–925 (2003). https://doi.org/10.1007/s11661-003-0222-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-003-0222-x