Abstract

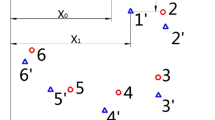

Various microstructure-level finite element models were generated according to the real microstructure of DP590 steel to capture the mechanical behavior and fracture mode. The failure mode of the dual-phase (DP) steels, mainly resulting from microstructure-level inhomogeneity and initial geometrical imperfection, was predicted using the plastic strain localization theory. In addition, dog-bone-type tensile test specimens with different edge qualities were prepared and the deformation processes were recorded using a digital image correlation system. When the steel exhibited no initial geometrical imperfection, void initiation was triggered by decohesion between martensite and ferrite which was predicted based on the severe strain concentration, or tensile stress in areas where stress triaxiality and strain values were high. Final failure was caused by shear localization in the vicinity. Moreover, the initial geometrical imperfections severely affected the overall ductility and failure mode of the DP590 steel. When initial geometrical imperfections were deeply ingrained, an incipient crack began at the site of initial geometrical imperfection, and then caused progressive damage throughout the microstructure, from the area of shear localization to the final fracture. Overall, the depth of the geometrical imperfection was the critical factor in determining whether internal decohesion or a local crack plays a dominant role.

Similar content being viewed by others

References

Rashid M S. GM 980X-a unique high strength sheet steel with superior formability. SAE Technical Paper 760206, Society of Automotive Engineers, Warrendale, PA. 1976

Rashid M S, Cprek E R. Relationship between microstructure and formability in two high-strength, low-alloy steels. In: ASTM Special Technical Publication 647, ASTM, Philadelphia, PA, 1976: 174–190

Sartkulvanich P, Kroenauer B, Golle R, et al. Finite element analysis of the effect of blanked edge quality upon stretch flanging of AHSS. CIRP Ann-Manuf Techn, 2010, 59: 279–282

Konieczny A, Henderson T. On formability limitations in stamping involving sheared edge stretching. SAE Technical Paper 2007-01-0340, doi:10.4271/2007-01-0340

Wiedenmann R, Sartkulvanich P, Altan T. Finite element analysis on the effect of sheared edge quality in blanking upon hole expansion of advanced high strength steel. IDDRG 2009, Golden, CO, USA, 2009: 559–570

Wu X, Bahmanpour H, Schmid K. Characterization of mechanically sheared edges of dual phase steels. J Mater Process Tech, 2012, 212: 1209–1224

Socrate S, Boyce M C. Micromechanics of toughened polycarbonate. J Mech Phys Solids, 2000, 48: 233–273

Al-Abbasi F M, Nemes J A. Micromechanical modeling of dual phase steels. Int J Mech Sci, 2003, 45: 1449–1465

Hosseini-Toudeshky H, Anbarlooie B, Kadkhodapour J, et al. Microstructure deformation pattern and mechanical behavior analyses of DP600 dual phase steel. Mater Sci Eng A, 2014, 600: 108–121

Ramazani A, Mukherjee K, Prahl U, Bleck W. Modelling the effect of microstructural banding on the flow curve behavior of dual-phase (DP) steels. Comp Mater Sci, 2012, 52: 46–54

Li Y, Karr D G. Prediction of ductile fracture in tension by bifurcation, localization, and imperfection analysis. Int J Plasticity, 2008, 25: 1128–1153

Marciniak Z, Kuczynski K. Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci, 1967, 9: 609–612

Aretz H. Numerical analysis of diffuse and localized necking in orthotropic sheet metals. Int J Plasticity, 2007, 23: 798–840

Aretz H. A simple isotropic-distortional hardening model and its application in elastic-plastic analysis of localized necking in orthotropic sheet metals. Int J Plasticity, 2008, 24: 1457–1480

Sanchez P J, Huespe A E, Oliver J. On some topics for the numerical simulation of ductile fracture. Int J Plasticity, 2008, 24: 1008–1038

Uthaisangsuk V, Prahl U, Bleck W. Micromechanical modeling of damage behavior of multiphase steels. Comp Mater Sci, 2008, 43: 27–35

Uthaisangsuk V, Prahl U, Bleck W. Stretch-flangeability characterisation of multiphase steel using a microstructure based failure modeling. Comp Mater Sci, 2009, 45: 617–623

Uthaisangsuk V, Muenstermann S, Prahl U, et al. A study of microcrack formation in multiphase steel using representative volume element and damage mechanics. Comp Mater Sci, 2011, 50: 1225–1232

Vajragupta N, Uthaisangsuk V, Schmaling B, et al. A micromechanical damage simulation of dual phase steels using XFEM. Comp Mater Sci, 2012, 54: 271–279

Ramazani A, Schwedt A, Aretz A, et al. Characterization and modelling of failure initiation in DP steel. Comp Mater Sci, 2013, 75: 35–44

Chatzigeorgiou G, Charalambakis N. Instability analysis of non-homogeneous materials under biaxial loading. Int J Plasticity, 2005, 11: 949–970

Sun X, Choi K S, Soulami A, et al. On key factors influencing ductile fractures of dual phase (DP) steels. Mater Sci Eng A, 2009, 526: 140–149

Sun X, Choi K S, Liu W N, et al. Predicting failure modes and ductility of dual phase steels using plastic strain localization. Int J Plasticity, 2009, 25: 1888–1909.

Paul S K. Micromechanics based modeling of dual phase steels: Prediction of ductility and failure modes. Comp Mater Sci, 2012, 56: 34–42

LePera F S. Improved etching technique for the determination of percent martensite in high-strength dual-phase steels. Metallography, 1979, 12: 263–268

Jiang Z H, Guan Z Z, Lian J S. The relationship between ductility and material parameters for dual phase steel. J Mater Sci, 1993, 28: 1814–1818

Bag A, Ray K K, Dwarakadasa E S. Influence of martensit content and morphology on tensile and impact properties of high-martensite dual-phase steels. Metall Mater Trans, 1999, 30: 1193–1202.

Grujicic M, Erturk T, Owen W S. A finite element analysis of the effect of the accommodation strains in the ferrite phase on the work hardening of a dual-phase steel. Mater Sci Eng, 1986, 82: 151–159

Ilie D E, O’Donnel B P, McGarry J P, et al. Computational modeling of the extrusion of an Al-SiC metal matrix composite using macroscale and microscale methods. J Strain Anal Eng, 2007, 42: 237–252

Kouznetsova V G. Computational homogenization for the multi-scale analysis of multiphase materials. Dissertation of Doctor Degree. Technical University Eindhoven, 2002

Rodriguez R M, Gutierrez I. Unified formulation to predict the tensile curves of steels with different microstructures. Mater Sci Forum, 2003, 426–432: 4525–4530

Zheng H, Wu Y J, Diao K S, et al. Experimental investigation of sheared edge’s influence on tensile properties of DP steel (in Chinese). J Shanghai Jiaotong Univ, 2014, 48: 405–411

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhuang, X., Xu, C. & Zhao, Z. Experimental and numerical investigation of failure mode in geometrically imperfect DP590 steel. Sci. China Technol. Sci. 58, 476–484 (2015). https://doi.org/10.1007/s11431-015-5772-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-015-5772-9