Abstract

The failure of thin film-substrate structure occurs mainly at the thin film or the interface. However, the characterizing and estimating methods of failure stress in thin film are neither uniform nor effective because there are some complex effects of such as size, interface and stress state on the failure behavior of thin film-substrate structure. Based on the scanning electron microscope (SEM) in-situ investigation on the failure models of the Cu thin film-substrate structure and the nano scratched testing results, the failure stresses in different thicknesses of the Cu film-substrate were characterized, which were compared and confirmed by other methods, such as Stoney formula and other empiric equations. These results indicate that the novel estimating method of failure stress in thin film based on the critical wavelength of surface unstable analysis is better than other methods. The main reason is that the novel estimating method of failure stress in meso thickness film fully considered the effect factors of free surface unstable behavior and elastic anisotropy of thin film. Therefore, the novel estimating method of failure stress assists people to understand the critical interfacial strength and to set up the failure criterion of thin film-substrate structure.

Similar content being viewed by others

References

Xu B S. Physics and Chemistry of Material Interface (in Chinese). Beijing: Chemical Industry Press, 2006

Ye H Q. Structure and Property of Material Interface (in Chinese). Beijing: Science Press, 1999

Ernst F. Metal-oxide interface. Mater Sci Eng, 1995, 14(3): 97–156

Wang X S. Test and Analysis on Mechanical Behavior of Materials (in Chinese). Beijing: Tsinghua University Press, 2007. 107–123

Wang X S, Fan J H. An evaluation the growth rate of small fatigue cracks in cast AM50 magnesium alloy at different temperature in vacuum environment. Int J Fatigue. 2006, 28(1): 79–86. doi: 10.1016/j.ijfatigue.2005.03.004

Wang X S, Liang F, Fan J H, et al. Investigations on low-cycle fatigue small crack initiation and propagation mechanism of cast magnesium alloys based on in-situ observation with SEM. Philos Mag, 2006, 86(11): 1581–1596. doi:10.1080/14786430500401070

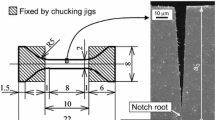

Wang X S, Huang J G, Meng X K. SEM in-situ investigation on micro failure characterizations of multi Cu/Ni films under bending loading (in Chinese). Chin J Mater Res, 2007, 21(Suppl): 182–185

Huang J G, Wang X S, Meng X K. SEM in situ study on deformation behavior of Cu and Cu/Ni films under three-point bending. Mater Trans, 2007, 48: 2795–2798. doi: 10.2320/matertrans.MRP2007069

Li Y, Wang X S, Meng X K. Buckling behavior of metal film/substrate structure under pure bending. Appl Phys Lett, 2008, 92: 131902. doi:10.1063/1.2897035

Li Y, Wang X S, Fan Q S. Effects of elastic anisotropy on the surface stability of thin film/substrate system. Int J Eng Sci. 2008, 46: 1325–1333. doi: 10.1016/j-ijengsci.2008.07/008

Wang X S, Yan C K, Li Y, et al. SEM in-situ study on failure of nanocrystal metallic thin films and substrate structure under three point bending. Int J Fracture, 2008, 15: 269–279. doi: 10.1007/s10704-008-9257-8

Xiang Y, Li T, Suo Z, et al. High ductility of metal film adherent on a polymer substrate. Appl Phys Lett, 2005, 87: 161910. doi: 10.1063/1.2108110

Park H S, Kwon D. An energy approach to quantification of adhesion strength from critical loads in scratch tests. Thin Solid Films, 1997, 307: 156–162

Stoney G G. Tension of electro-deposited films. Proc R Soc London, 1909, 82: 172–175

Asaro R J, Tiller W A. Interface morpohology development during stress corrosion cracking: part I, via surface diffusion. Metall Trans, 1972, 3: 1789–1996

Allen H G. Stiffness and strength of 2 glass-fiber reinforced cement laminates. J Comp Mater, 1971, 5: 194–207

Allen H G. Analysis and Design of Structural Sandwich Panels. Oxford: Pergamon Press, 1969

Yan G, White J R. Residual stress development in a bi-layer coating. Pol Eng Sci, 1999, 39(10): 1856–1865

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Foundation of China (Grant No. 10772091) and National Basic Research Program of China (Grant Nos. 2004CB619304-5, 2007CB936803)

Rights and permissions

About this article

Cite this article

Wang, X., Li, Y. & Meng, X. An estimation method on failure stress of micro thickness Cu film-substrate structure. Sci. China Ser. E-Technol. Sci. 52, 2210–2215 (2009). https://doi.org/10.1007/s11431-009-0235-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-009-0235-9