Abstract

Purpose

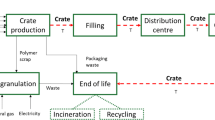

The aim of this study is to assess the life cycle carbon footprint of the New Zealand kiwifruit packaging and transport supply chain to retailers in two major markets (Japan and Germany). Results of this study have been used to identify areas of the New Zealand kiwifruit packaging and transport supply chain that contribute significantly to the carbon footprint and to identify options for reduction.

Methods

This study is based on the ISO standards for life cycle assessment (namely, ISO 14040:2006 and ISO 14044:2006). The PAS 2050 also provided further methodological guidance. Primary packaging data were sourced from Zespri’s suppliers. End-of-life data were sourced from the market and waste statistics of the relevant countries. Gabi 4.4 was used for upstream material information and modelling.

Results and discussion

The carbon footprint of the packaging and transport of kiwifruit ranged from 0.33 to 0.67 kg CO2e per kilogram of fruit delivered to a store depending on pack type and market. Shipping accounted for the majority of these emissions (58–82 %), and Zespri is actively working with shipping companies to reduce this. There are also opportunities to reduce the carbon footprint through reducing the amount of fruit repacked in the market, using trains for long-distance transport and increasing packaging recycling rates.

Conclusions

There is a range of options for reducing the carbon footprint of the New Zealand kiwifruit packaging and transport supply chain. These will tend to be incremental (i.e. a number of small gains) and would involve working closely with partners in the supply chain. Options include increased efficiency in shipping, use of trains for land transport, reductions in the addition of structural packaging in the market, managing the product mix to minimize those supply chains with a higher carbon footprint, identifying alternative material for components of the packaging, replacing the use of polystyrene clamshells with alternative materials or plastic bags and maximizing recycling rates along all stages of the supply chain.

Similar content being viewed by others

References

BSI PAS 2050 (2008) Specification for the assessment of the life cycle greenhouse gas emissions of goods and services. Downloaded from http://shop.bsigroup.com/en/Browse-By-Subject/Environmental-Management-and-Sustainability/PAS-2050/

DEFRA (2011) Guidelines to Defra/DECC’s GHG conversion factors for company reporting. 50 pgs. Downloaded from http://archive.defra.gov.uk/environment/business/reporting/pdf/110819-guidelines-ghg-conversion-factors.pdf

Fitzgerald WB, Howitt OJA, Smith IJ (2011) Greenhouse gas emissions from the international maritime transport of New Zealand’s imports and exports. Energy Policy 39(3):1521–1531

Gaudreault C, Vice K (2011) Summary of the literature on the treatment of paper and paper packaging products recycling in life cycle assessment. NCASI Technical Bulletin No. 985, May 2011. Downloaded from www.ncasi.org/Search-Results.aspx?q=TB%200985

Google Maps (2009) Directions. Accessed at www.google.com/maps

ISO 14040 (2006) Environmental management—life cycle assessment—principles and framework

ISO 14044 (2006) Environmental Management—life cycle assessment—Requirements and guidelines

McCallum D (2009) Carbon footprint. Nelson Forests Ltd. pp 25. Downloaded from www.nzwood.co.nz/images/uploads/file/Nelson%20Forests%20LCA%20Study/Report_NFL_CarbonFootprint_V61.pdf

McLaren S, Smith A, Mithraratne N, Cleland D, Marquardt M, Frater G, Barber A, Rothman M (2008) Carbon footprinting for the kiwifruit supply chain—report on implementation. ZESPRI Contract Report

Mithraratne N, Barber A, McLaren S (2010) Carbon footprinting for the kiwifruit supply chain. Report on Methodology and Scoping Study Final Report. Downloaded from www.lcanz.org.nz/sites/default/files/17/kiwifruit_methodology_report_revised_2010.pdf

Paper Recycling Promotion Centre (2009) Paper recycling in Japan. Downloaded from www.prpc.or.jp/menu05/pdf/english-paperrecycling.pdf

Plastic Waste Management Institute, Japan (2011) Plastic products, plastic waste and resource recovery (2009). PWMI Newsletter No. 40, 2011.5. Downloaded from www.pwmi.or.jp/ei/siryo/ei/ei_pdf/ei40.pdf

Portworld (2009) Distance calculator. Accessed at www.portworld.com/map/

Sandilands J, Nebel B, Hodgson C, Hall P (2009) Greenhouse gas emissions of the Forestry Sector in New Zealand. Scion, Rotorua, New Zealand, pp 40. Downloaded from www.mpi.govt.nz/news-resources/publications.aspx?title=Greenhouse%20Gas%20emissions%20of%20the%20Forestry%20Sector%20in%20New%20Zealand

Wild Ing. Yves GmbH (2008) Environmental aspects of the transport of Reefer containers, 3rd Reefer logistics conference. 24–26 June 2008. Antwerp, Belgium

Acknowledgments

This study was funded by Zespri International Ltd. Our thanks go to Alistair Mowat at Zespri for his constructive feedback throughout the project. Glen Arrowsmith and Janet Clendon at Zespri provided us with information on supply chains and packaging specifications. Zespri packaging suppliers and upstream supply chain businesses were great at providing data. We also appreciate the advice received from Babara Nebel and David Drysdale at PE Australasia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Sarah McLaren

Rights and permissions

About this article

Cite this article

Robertson, K., Garnham, M. & Symes, W. Life cycle carbon footprint of the packaging and transport of New Zealand kiwifruit. Int J Life Cycle Assess 19, 1693–1704 (2014). https://doi.org/10.1007/s11367-014-0775-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-014-0775-5