Abstract

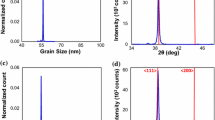

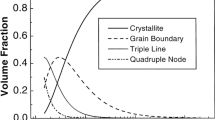

Nanocrystalline metals exhibit a phenomenon called plastic strain recovery whereby plastic strain introduced through a load cycle is gradually recovered under no external loading over a time period of hours and days. In this study, we experimentally explore the diffusive mechanisms and the strain rates for nanocrystalline thin films of copper with an average grain size of about 35 nm during plastic strain recovery and creep. The experiments are performed via the plane strain bulge test and the thin film samples are deposited using thermal evaporation and sputtering. The specimens recover their residual strain in a period of time with two characteristic strain rates, a transient strain recovery rate of the order of 10−7/s and a steady-state strain recovery rate of the order of 10−9/s and there is a characteristic time at which the transition occurs between the two rates. The results suggest that a diffusive mechanism in conjunction with voids within the nanocrystalline material can explain the two plastic strain recovery rates and the transition between the two.

Similar content being viewed by others

References

Hall EO (1951) The deformation and ageing of mild steel: Iii discussion of results. Proc Phys Soc 64(32)

Petch NJ (1953) The cleavage strength of polycrystals. J Iron Steel Inst:173

Gleiter H (1989) Nanocrystalline materials. Progress Mater Sci 33(4):223–315

Gleiter H (2000) Nanostructured materials: basic concepts and microstructure. Acta Materialia 48(1):1–29

Kumar KS, Swygenhoven HV, Suresh S (2003) Mechanical behavior of nanocrystalline metals and alloys. Acta Materialia 51(19):5743–5774. The Golden Jubilee Issue. Selected topics in Materials Science and Engineering: Past, Present and Future

Weertman JR (2007) Nanostructured materials: processing, properties and applications, 2nd edn. William Andrew Inc, NY, p 537

Wei X, Kysar JW (2011) Residual plastic strain recovery driven by grain boundary diffusion in nanocrystalline thin films. Acta Materialia 59(10):3937–3945

Rajagopalan J, Han JH, Saif MTA (2007) Plastic deformation recovery in freestanding nanocrystalline aluminum and gold thin films. Science 315(5820):1831–1834

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Progress Mater Sci 51(4):427–556

Wei Y, Bower AF, Gao H (2008) Recoverable creep deformation and transient local stress concentration due to heterogeneous grain-boundary diffusion and sliding in polycrystalline solids. J Mech Phys Solids 56(4):1460–1483

Swygenhoven HV, Derlet PM (2001) Grain-boundary sliding in nanocrystalline fcc metals. Phys. Rev. B 64(9):224105

Wei YJ, Anand L (2004) Grain-boundary sliding and separation in polycrystalline metals: application to nanocrystalline fcc metals. J Mech Phys Solids 52(11):2587–2616

Keblinski P, Wolf D, Gleiter H (1998) Molecular-dynamics simulation of grain-boundary diffusion creep. Inter Sci 6:205–212

Schiotz J, Di Tolla FD, Jacobsen KW (1998) Softening of nanocrystalline metals at very small grain sizes. Nature 391(6667):561–563, 02

Conrad H, Narayan J (2000) On the grain size softening in nanocrystalline materials. Scripta Materialia 42(11):1025–1030, 5

Wolf D, Yamakov V, Phillpot SR, Mukherjee AK (2003) Deformation mechanism and inverse hall–petch behavior in nanocrystalline materials. Zeitschrift für Metallkunde 94(10):1091–1097, 2015/04/27

Wei Q, Cheng S, Ramesh KT, Ma E (2004) Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals. Mater Sci Eng A 381:71–79

Wei Y, Bower A F, Gao H (2008) Enhanced strain-rate sensitivity in fcc nanocrystals due to grain-boundary diffusion and sliding. Acta Materialia 56(8):1741–1752

Arzt E (1998) Size effects in materials due to microstructural and dimensional constraints: a comparative review. Acta Materialia 46(16):5611–5626

Gad el Hak M (2001) The MEMS Handbook. CRC Press

Bhushan B, Li X (2003) Nanomechanical characterisation of solid surfaces and thin films. Int Mater Rev 48(3):125–164

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19:3–20, 1

Chen X, Vlassak JJlassak JJ (2001) Numerical study on the measurement of thin film mechanical properties by means of nanoindentation. J Mater Res 16:2974–2982, 10

Tsui TY, Vlassak JJ, Nix WD (1999) Indentation plastic displacement field: Part i. the case of soft films on hard substrates. J Mater Res 14:2196–2203, 6

Hong S, Weihs TP (1989) Residual stresses in thin film using microcantilever beams in thin films. Stress Mech Prop 130:93–98

Baker SP, Nix WD (1994) Mechanical properties of compositionally modulated au-ni thin films: nanoindentation and microcantilever deflection experiments. J Mater Res 9:3131–3144, 12

Baker SP, Keller-Flaig RM, Shu JB (2003) Bauschinger effect and anomalous thermomechanical deformation induced by oxygen in passivated thin cu films on substrates. Acta Materialia 51(10):3019–3036

Xiang Y, Chen X, Vlassak JJ (2005) Plane-strain bulge test for thin films. J Mater Res 20:2360–2370, 9

Han SW, Lee HW, Lee HJ, Kim JY, Kim JH, Oh CS, Choa SH (2006) Mechanical properties of au thin film for application in mems/nens using microtensile test. Curr Appl Phys 6, Supplement 1 (0):e81 – e85. Nano Korea 2005 Symposium Nano Korea 2005 Symposium

Freund LB, Suresh S (2003) Thin film materials: stress, defect formation, and surface evolution. Cambridge University Press, New York

Zhou W, Yang J, Sun G, Liu X, Fuhua Y, Jinmin L (2008) Fracture properties of silicon carbide thin films by bulge test of long rectangular membrane. J Microelectromech Syst 17(2):453–461

Tugcu P, Neale KW, Wu PD, Inal K (2004) Crystal plasticity simulation of the hydrostatic bulge test. Int J Plastic 20:1603–1653

Gruber PA, Böhm J, Onuseit F, Wanner A, Spolenak Rcand Arzt E (2008) Size effects on yield strength and strain hardening for ultra-thin cu films with and without passivation: a study by synchrotron and bulge test techniques. Acta Materialia 56(10):2318–2335

Huang CK, Lou WM, Tsai CJ, Wu TC, Lin HY (2007) Mechanical properties of polymer thin film measured by the bulge test. Thin Solid Films 515(18):7222–7226

Vlassak JJ, Nix WD (1992) A new bulge test technique for the determination of young’s modulus and poisson’s ratio of thin films. J Mater Res 7(12):3242–3249

Xiang Y, Chen X, Vlassak JJ (2005) Plane-strain bulge test for thin films. J Mater Res 20(9):2360–2370

Vlassak JJ, Nix WD (1992) A new bulge test technique for the determination of young’s modulus and poisson’s ratio of thin films. J Mater Res 7:3242–3249, 12

Wei X, Lee D, Shim S, Chen X, Kysar JW (2007) Plane-strain bulge test for nanocrystalline copper thin films. Scripta Materialia 57(6):541–544

Yong X, Tsui T Y, Vlassak JJ, McKerrow AJ (2004) Measuring the elastic modulus and ultimate strength of low-k dielectric materials by means of the bulge test:133

Zhou W, Yang J, Li Y, Ji A, Yang F, Yu Y (2009) Bulge testing and fracture properties of plasma-enhanced chemical vapor deposited silicon nitride thin films. Thin Solid Films 517(6):1989–1994

Xiang Y, Tsui TY, Vlassak JJ (2006) The mechanical properties of freestanding electroplated cu thin films. J Mater Res 21:1607–1618, 6

Hencky H (1915) About the stress state in circular plates with negligible bending stiffness. Math Phys 63 (311)

Vlassak JJ (1994) New experimental techniques and analysis methods for study of mechanical properties of materials in small volumes. PhD thesis, Stanford University, Stanford, CA

Tabata O, Kawahata K, Sugiyama S, Igarashi I (1989) Mechanical property measurments of thin films using load-deflection of composite rectangular membrane. In: Proceeding, micro electro mechanical systems IEEE, pp 152–156

Lin P (1990) The in-situ measurement od mechanical properties of multi-layer coatings. PhD thesis, Massachusetts Institue of Technology, Cambridge, MA

Timoshenko S, Woinowsky-Krieger S (1959) Theory of plates and shells. McGraw-Hill, New York

Maseeh F, Senturia SD (1990) Viscoelasticity and creep recovery of polyimide thin films. IEEE Solid-State Sensor Actuator Workshop:55

Kelly PJ, Arnell RD (1999) Control of the structure and properties of aluminum oxide coatings deposited by pulsed magnetron sputtering. J Vacuum Sci Technol 17:945

Kelly PJ, Arnell RD (2000) Magnetron sputtering: a review of recent developments and applications. Vacuum 56(3):159–172

Scherrer P (1918) Estimation of the size and internal structure of colloidal particles by mean of rontgen. Nachr GEs Wiss Gottingen 2:96–100

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metallurgica 1(1):22–31

Cullity BD (2001) Elements of x-ray diffraction, 3rd edn. Prentice Hall, Upper Saddle River

Warren BE, Averbach BL (1950) The effect of cold-work distortion on x-ray patterns. J Appl Phys 21(595)

Sanchez-Bajo F, Cumbrera FL (1997) The use of the pseudo-voigt function in the variance method of x-ray line-broadening analysis. J Appl Cryst 30:427–430

Standard test methods for determining average grain size. ASTM International (2013)

International A. Metals Handbook:. ASM International, Materials Park, Ohio (1990)

Fougere GE, Riester L, Ferber M, Weertman JR, Siegel RW (1995) Young’s modulus of nanocrystalline Fe measured by nanoindentation. Mater Sci Eng A-Struct Mater Prop Microstruct Process 204(1–2):1–6. Symposium on Engineering of Nanostructured Materials, BOSTON, MA, NOV 28-30, 1994

Coble RL (1963) A model for boundary diffsuion controlled creep in polycrystalline materials. J Appl Phys 34:1679–1682

Yamakov V, Wolf D, Phillpot SR, Gleiter H (2002) Grain-boundary diffusion creep in nanocrystalline palladium by molecular-dynamics simulation. Acta Materialia 50(1):61–73

Karch J, Birringer R, Gleiter H (1987) Ceramics ductile at low temperature. Nature 330(6148):556–558, 12

Nieman GW, Weertman JR, Siegel RW (1991) Mechanical behavior of nanocrystalline cu and pd. J Mater Res 6(5):1012–1027

Hugo RC, Kung H, Weertman JR, Mitra R, Knapp JA, Follstaedt DM (2003) In-situ tem tensile testing of dc magnetron sputtered and pulsed laser deposited ni thin films. Acta Materialia 51:1937–1943

Acknowledgments

The authors gratefully acknowledge support from the National Science Foundation (NSF DMR-1310503).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghazi, N., Kysar, J.W. Experimental Investigation of Plastic Strain Recovery and Creep in Nanocrystalline Copper Thin Films. Exp Mech 56, 1351–1362 (2016). https://doi.org/10.1007/s11340-016-0169-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0169-7