Abstract

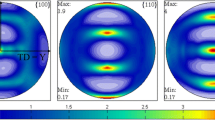

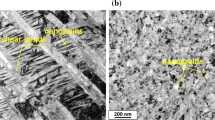

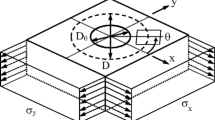

Technical components produced via sheet metal forming often obtain characteristic crystallographic textures and process induced residual stress distributions. Knowledge of the local residual stress states is essential for the proper components’ dimensioning. We report about the expansion of the incremental hole drilling technique for residual stress analysis to highly textured material states. A new evaluation approach using the differential evaluation algorithm is proposed, which bases on the calculation of multiple case specific calibration functions under consideration of the local orientation distribution function of the textured material. Systematic finite element (FE) simulations of incremental hole-drilling experiments are conducted regarding defined ideal nickel single crystal orientations (cube, Goss and brass). Multiple case-specific calibration functions, which consider the materials elastic anisotropy, are calculated and applied for stress calculation. In addition, the influence of a rosette misorientation between stress measurement and FE calibration is investigated. Using this new evaluation strategy a significant improvement of (residual) stress calculation on strongly textured materials is achieved. Finally, the capability of the proposed evaluation approach is experimentally validated for an uniaxially loaded CMSX-4 (nickel base super alloy) single crystal. The investigation clearly proved that in case of strongly anisotropic materials the evaluation using multiple case-specific calibration functions leads to a significant improvement in stress analysis compared to a conventional evaluation.

Similar content being viewed by others

References

Kocks UF, Tomé CN, Wenk HR (1998) Texture and Anisotropy. Cambridge University Press, Cambridge

Macherauch E, Müller P (1961) Das sin2ψ-verfahren der röntgenographischen spannungsmessung. Z Phys 13:340–345

Hauk V, Herlach D, Sesemann H (1975) Über nichtlineare gitterebenenabstandsverteilungen in stählen, ihre entstehung, berechnung und berücksichtigung bei der spannungsermittlung. Z Metallkde 66:734–737

Eigenmann B, Macherauch E (1995) Röntgenographische untersuchung von spannungszuständen in werkstoffen – teil I. Mat-wiss u Werkstofftech 26:148–160

Hauk V, Vaessen G (1985) Eigenspannungen in kristallitgruppen texturierter stähle. Z Metallkde 76:102–107

Hauk V, Oudelhoven R (1988) Eigenspannungsanalyse an kaltgewalztem nickel. Z Metallkde 79:41–49

Behnken H, Hauk V (1991) Berechnung der röntgenographischen spannungsfaktoren texturierter werkstoffe – vergleich mit experimentellen ergebnissen. Z Metallkde 82:151–158

Moore MG, Evans WP (1958) Mathematical correction for stress in removed layers in X-Ray diffraction residual stress analysis. SAE Trans 66:340–345

Wang YD, Wang XL, Stoica AD, Richardson JW (2002) Measurement of grain-orientation-dependent stress and stored energy using a spallation neutron source. Mater Sci Forum 408–412:179–184

ASTM E837-08. Standard Test Method for Determining Residual Stresses by Hole-Drilling Strain-Gage method

Schwarz T (1996) Beitrag zur Eigenspannungsermittlung an isotropen, anisotropen sowie inhomogenen, schichtweise aufgebauten Werkstoffen mittels Bohrlochmethode und Ringkernverfahren. Dissertation, University of Stuttgart

Schajer GS, Yang L (1994) Residual-stress measurement in orthotropic materials using the hole-drilling method. Exp Mech 34:324–333

Schuster S, Gibmeier J (2014) Residual stress analysis of strongly textured materials by means of the incremental hole-drilling method – survey on the application limits. Mater Test 56:915–922

Mathar J (1933) Ermittlung von eigenspannungen durch messung von bohrloch-verformungen. Arch Eisenhuttenwes 7:277–281

Nelson DV, Makino A, Schmidt T (2006) Residual stress determination using hole drilling and 3D image correlation. Exp Mech 46:31–38

Lord JD, Penn D, Whitehead P (2008) The application of digital image correlation for measuring residual stress by incremental hole drilling. Appl Mech Mater 13–14:65–73

Nicoletto G (1991) Moiré interferometry determination of residual stresses in the presence of gradients. Exp Mech 31:252–256

Wu Z, Lu J, Han B (1998) Study of residual stress distribution by a combined method of moiré interferometry and incremental hole drilling, part I: theory. J Appl Mech 65:837–843

Schwarz RC, Kutt LM, Papazian JM (2000) Measurement of residual stress using interferometric moire: a new insight. Exp Mech 40:271–281

Makino A, Nelson DV (1994) Residual-stress determination by single-axis holographic interferometry and hole drilling - part I: theory. Exp Mech 34:66–78

Steinzig M, Ponslet E (2003) Residual stress measurement using the hole drilling method and laser speckle interferometry: part I. Exp Techniques 27:43–46

Schajer GS (2010) Advances in hole-drilling residual stress measurements. Exp Mech 50:159–168

Schajer GS (2010) Hole-drilling residual stress measurement at 75: origin, advances, opportunities. Exp Mech 50:245–253

Schajer GS (1988) Measurement of non-uniform residual stresses using the hole-drilling method part I. Stress calculation procedures. J Eng Mater-T ASME 110:338–343

Schajer GS (1988) Measurement of non-uniform residual stresses using the hole-drilling method part II. Practical application of the integral method. J Eng Mate-T ASME 110:344–349

Schwarz T, Kockelmann H (1993) Die bohrlochmethode - eine für viele anwendungsbereiche optimales verfahren zur experimentellen ermittlung von eigenspannungen. Messtechnische Briefe 29:33–38

König G (1991) Ein Beitrag zur Weiterentwicklung teilzerstörender Eigenspannungsmeßverfahren. Dissertation University of Stuttgart

Rendler NJ, Vigness I (1966) Hole-drilling strain-gage method of measuring residual stresses. Exp Mech 6:577–586

von Mirbach D (2014) Experimental validation of the calibration function of the hole drilling method and ring core method for residual stress measurement. Mater Test 56:184–190

Sobolevski EG, Nau A, Scholtes B (2011) Residual stress analysis using the hole-drilling method and geometry-specific calibration functions. Mater Sci Forum 681:159–164

Obelode E, Gibmeier J (2013) Residual stress analysis on thick film systems by the incremental hole-drilling method – simulation and experimental results. Exp Mech 53:965–976

Landolt-Börnstein (1992) Group III Condensed Matter, Table 3. Cubic system. Elements, 29a:14, Springer

Voigt W (1928) Lehrbuch der kristallphysik. Teubner, Leipzig

Reuss A (1929) Berechnung der fließgrenze von mischkristallen auf grund der plastizitätsbedingung für einkristalle. Z Angew Math Mech 9:49–58

Hill R (1952) The elastic behaviour of a crystalline aggregate. Proc Phys Soc A 65:349–354

Kröner E (1958) Berechnung der elastischen konstanten des vielkristalls aus den konstanten des einkristalls. Z Phys 151:504–518

Acknowledgment

The Graduate School 1483 “Process chains in production: Modelling, interactions and assessments of process zones” and the German research foundation (DFG) are gratefully acknowledged for funding. Further, we thank Mike Steinzig (Los Alamos National Laboratory, USA), who provided the hole drilling measuring setup used for experimental validation during Simone’s stay at LANL.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schuster, S., Gibmeier, J. Incremental Hole Drilling for Residual Stress Analysis of Strongly Textured Material States – A New Calibration Approach. Exp Mech 56, 369–380 (2016). https://doi.org/10.1007/s11340-015-0104-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0104-3