Abstract

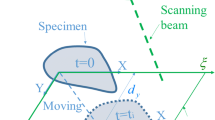

In this paper, we propose segmentation-aided digital image correlation (SA-DIC) for measuring the deformation near the interface between two contact bodies. Conventional DIC assumes that the shape function correctly warps a square subset from the reference image to the deformed image. When the subset is close to the contact interface, it contains pixels from the two contact bodies and the background if clearance is present. The displacement field in the subset is greatly complicated by the induced discontinuity and mismatches the shape function. To resolve this problem, SA-DIC automatically segments the image pixels into three categories: the two contact bodies and the invalid area. By using complementary speckle patterns, the contact interface exhibits a sharp intensity transition and it is extracted by edge detection. The background pixels are identified from the difference of the reference image pair captured with distinct background. Based on the image segmentation, only the pixels belonging to the same category are included in the subset. Their displacements are homogeneous and thus well characterized by the shape function used in DIC. Both simulated and real-world experiments are carried out to evaluate the proposed method and compare with conventional DIC. The results show that SA-DIC is able to measure the localized deformation due to the contact, while conventional DIC generates large errors near the contact interface and falsely locates the most deformed areas.

Similar content being viewed by others

References

Barber J, Ciavarella M (2000) Contact mechanics. Int J Solids Struct 37(1):29–43

Wang M-J (2003) A new photoelastic investigation of the dynamic bending stress of spur gears. J Mech Des 125(2):365–372

Papanikos P, Meguid S, Stjepanovic Z (1998) Three-dimensional nonlinear finite element analysis of dovetail joints in aeroengine discs. Finite Elem Anal Des 29(3):173–186

Song W, Keane A, Rees J, Bhaskar A, Bagnall S (2002) Turbine blade fir-tree root design optimisation using intelligent cad and finite element analysis. Comput Struct 80(24):1853–1867

Chan S, Tuba I (1971) A finite element method for contact problems of solid bodies part ii. application to turbine blade fastenings. Int J Mech Sci 13(7):627–639

Meguid S, Kanth P, Czekanski A (2000) Finite element analysis of fir-tree region in turbine discs. Finite Elem Anal Des 35(4):305–317

Li S (2007) Finite element analyses for contact strength and bending strength of a pair of spur gears with machining errors, assembly errors and tooth modifications. Mech. Mach. Theory 42(1):88–114

Petrov E, Ewins D (2006) Effects of damping and varying contact area at blade-disk joints in forced response analysis of bladed disk assemblies. J Turbomach 128(2):403–410

Kenny B, Patterson E, Said M, Aradhya K (1991) Contact stress distributions in a turbine disc dovetail type joint-a comparison of photoelastic and finite element results. Strain 27(1):21–24

Burguete R, Patterson E (1997) A photoelastic study of contact between a cylinder and a half-space. Exp Mech 37(3):314–323

Spitas VA, Costopoulos TN, Spitas CA (2006) Optimum gear tooth geometry for minimum fillet stress using bem and experimental verification with photoelasticity. J Mech Des 128(5):1159–1164

Jones I, Truman C, Booker J (2008) Photoelastic investigation of slippage in shrink-fit assemblies. Exp Mech 48(5):621–633

Papadopoulos G (2004) Experimental estimation of the load distribution in bearings by the method of caustics. Exp Mech 44(4):440–443

Li M, Zhang J, Fang J, Shu D, Stronge W (2006) Dynamic analysis of contact forces in disc assemblies by the shadow method of caustics. J Strain Anal Eng Des 41(8):609–622

Spitas V, Papadopoulos G, Spitas C, Costopoulos T (2011) Experimental investigation of load sharing in multiple gear tooth contact using the stress-optical method of caustics. Strain 47(s1):e227–e233

Sutton MA, Orteu J-J, Schreier HW Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications. Springer, New York. doi:10.1007/978-0-387-78747-3

Pan B., Qian K., Xie H., Asundi A. (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol 20(6):062001

Wattrisse B, Chrysochoos A, Muracciole J-M, Némoz-Gaillard M (2001) Analysis of strain localization during tensile tests by digital image correlation. Exp Mech 41(1):29–39

Périé JN, Leclerc H, Roux S, Hild F (2009) Digital image correlation and biaxial test on composite material for anisotropic damage law identification. Int J Solids Struct 46(11):2388–2396

Shen B, Paulino G (2011) Direct extraction of cohesive fracture properties from digital image correlation: a hybrid inverse technique. Exp Mech 51(2):143–163

Wu T, Coret M, Combescure A (2011) Strain localisation and damage measurement by full 3d digital image correlation: Application to 15-5ph stainless steel. Strain 47(1):49–61

Cheng T, Xu X, Cai Y, Fu S, Gao Y, Su Y, Zhang Y, Zhang Q (2015) Investigation of portevin-le chatelier effect in 5456 al-based alloy using digital image correlation. Opt Lasers Eng 65:89–92

Jin H., Bruck H.A. (2005) Theoretical development for pointwise digital image correlation. Opt Eng 44 (6):067003–067003

Poissant J, Barthelat F (2010) A novel subset splitting procedure for digital image correlation on discontinuous displacement fields. Exp Mech 50(3):353–364

Pan B, Wang Z, Lu Z (2010) Genuine full-field deformation measurement of an object with complex shape using reliability-guided digital image correlation. Opt Express 18(2):1011–1023

Lu H, Cary P (2000) Deformation measurements by digital image correlation: implementation of a second-order displacement gradient. Exp Mech 40(4):393–400

Szeliski R (2010) Computer vision: algorithms and applications. Springer

Canny J (1986) A computational approach to edge detection, Pattern Analysis and Machine Intelligence. IEEE Trans 6:679–698

Zhou Y, Chen YQ (2012) Propagation function for accurate initialization and efficiency enhancement of digital image correlation. Opt Lasers Eng 50(12):1789–1797

Zhou Y, Sun C, Song Y, Chen J (2015) Image pre-filtering for measurement error reduction in digital image correlation. Opt Lasers Eng 65:46–56

Pan B, Asundi A, Xie H, Gao J (2009) Digital image correlation using iterative least squares and pointwise least squares for displacement field and strain field measurements. Opt Lasers Eng 47(7):865–874

Acknowledgments

This research work is supported by National Natural Science Foundation of China, Grant No.11372182 and No.11472267.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, C., Zhou, Y., Chen, J. et al. Measurement of Deformation Close to Contact Interface Using Digital Image Correlation and Image Segmentation. Exp Mech 55, 1525–1536 (2015). https://doi.org/10.1007/s11340-015-0055-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0055-8