Abstract

Stress applied to a material can be evaluated using ultrasonic waves. This practice is based on acoustoelastic theory, which relates the stress to the velocity of a wave traveling through the body. How the stress affects the wave velocity is determined by the material’s acoustoelastic constant. This constant can be experimentally measured or calculated from the material’s elastic constants. However, ultrasonic techniques have yet to be adopted as an inspection tool in the field. A factor contributing to this fact is the non-uniformity of materials, mostly associated with grain alignment or texture. As researchers consider this factor, they should take into account the anisotropy generated by rolling. The common practice, however, when relating strain and wave velocity is to ignore anisotropy and to simply utilize isotropic models. No studies have been performed to evaluate the effect of anisotropy on the stress measurement by ultrasound, especially for methods using critically refracted longitudinal waves. The aim of this study is to evaluate how the anisotropy generated by rolling affects the acoustoelastic effect for 7050 T7451 aluminum alloy. We compare the value of the acoustoelastic constant obtained experimentally for rolled samples to the constant calculated with measured elastic constants when the material is assumed to be isotropic. The results show that the methods yield different results, suggesting that the simplified isotropic model should be applied with caution. Since no true known value for elastic constants exists, the results can be used to approach the uncertainty when employing the isotropic model to evaluate stresses in aluminum alloys.

Similar content being viewed by others

References

Ruud CO (2000) Residual stress measurements. In: ASM Handbook: mechanical testing and evaluation, ASM International, Materials Park

Juvinall RC, Marshek KM (2005) Fundamentals of machine component design. Wiley, New York

Hughes DS, Kelly JL (1953) Second-order elastic deformation of solids. Phys Rev 92(4):1145–1149. doi:10.1103/PhysRev.92.1145

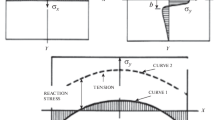

Duquennoy M, Ouaftouh M, Ourak M (1999) Ultrasonic evaluation of stresses in orthotropic materials using Rayleigh waves. NDT & E Int 32:189–199. doi:10.1016/S0963-8695(98)00046-2

Hu E, He Y, Chen Y (2009) Experimental study on the surface stress measurement with Rayleigh wave detection technique. Appl Acoust 70:356–360. doi:10.1016/j.apacoust.2008.03.002

Delsanto PP, Clark AV Jr (1987) Rayleigh wave propagation in deformed orthotropic materials. J Acoust Soc Am 81(4):952–960. doi:10.1121/1.394575

Ling Z, Zhou H, Zhang H (2009) Nondestructive pressure measurement in vessels using Rayleigh waves and LCR Waves. IEEE Trans Instrum Meas 58(5):1578–1584. doi:10.1109/TIM.2009.2012936

Schneider E, Goebbels K, Hiibschen G, Salzburger HJ (1981) Determination of residual stress by time-of-flight measurements with linear-polarized shear waves. Ultrason Symp 81:956–959

Janssen M (1988) Evaluation of an applied plane-stress tensor distribution using ultrasonic shear waves. Exp Mech 9:226–231. doi:10.1007/BF02329015

Nikitina NY, Ostrovsky LA (1998) An ultrasonic method for measuring stresses in engineering materials. Ultrasonics 35(8):605–610. doi:10.1016/S0041-624X(97)00154-6

Sasaki Y, Hasegawa M (2007) Effect of anisotropy on acoustoelastic birefringence in wood. Ultrasonics 46(2):184–190. doi:10.1016/j.ultras.2007.01.009

Fraga RS, Andrino MH, Santos AA (2009) Evaluation of the penetration depth of LCR waves for stress measurement. Proc. 3rd International conference on integrity, reliability and failure, Porto, Portugal

Egle DM, Bray DE (1976) Measurement of acoustoelastic and third order elastic constants for rail steel. J Acoust Soc Am 60(3):741–744. doi:10.1121/1.381146

Qozam H, Chaki S, Bourse G, Robin C, Walaszek H, Bouteille P (2010) Microstructure effect on the Lcr elastic wave for welding residual stress measurement. Exp Mech 50:179–185. doi:10.1007/s11340-009-9283-0

Santos AA, Santos GFM, Santos FC, Andrino MH, Rosário JM (2009) Application of Lcr waves to evaluate residual stresses in the RIM of railroad forged wheels. J Nondestruct Eval 28:91–100. doi:10.1007/s10921-009-0051-y

Johnson GC, Springer WC (1989) A comparison of measured and predicted second- and third-order elastic constants of a textured aggregate. Int J Solids Struct 25(6):609–619. doi:10.1016/0020-7683(89)90028-0

Duquennoy M, Ouaftouh M, Ourak M, Xu WJ (1999) Influence of natural and initial acoustoelastic coefficients on residual stress evaluation: theory and experiment. J Appl Phys 86(5):2490–2498. doi:10.1063/1.371082

Tanala E, Bourse G, Fremiot M, De Belevall JF (1995) Determination of near surface residual stresses on welded joints using ultrasonic methods. NDT & E Int 28(2):83–88. doi:10.1016/0963-8695(94)00013-A

Duquennoy M, Ouaftouh M, Ourak M, Jenot F (2002) Theoretical determination of Rayleigh wave acoustoelastic coefficients: comparison with experimental values. Ultrasonics 39:575–583. doi:10.1016/S0925-4005(98)00143-9

Stobbe DM (2005) Acoustoelasticity in 7075-T651 aluminum and dependence of third order elastic constants on fatigue damage. Dissertation, Georgia Institute of Technology

Guz AN, Makhort FG (2000) The physical fundamentals of the ultrasonic nondestructive stress analysis of solids. Int Appl Mech 36(9):1119–1149. doi:10.1023/A:1009442132064

Pao YH, Gamer U (1985) Acoustoelastic waves in orthotropic media. J Acoust Soc Am 77(3):806–812. doi:10.1121/1.392384

Pao YH, Sachse W, Fukuoka H (1984) Acoustoelasticity and ultrasonic measurements of residual stresses. In: Mason WP (ed) Thurston RN physical acoustics, 1st edn. Academic, New York, pp 61–143

Rose JL (1999) Ultrasonic waves in solid media. Cambridge University Press, New York

Bray DE, Stanley RK (1997) Nondestructive evaluation: a tool in design, manufacturing and service. CRC, Boca Raton

Harnish SF et al (2005) High high-temperature mechanical behavior and hot rolling of AA705X. Metall Mater Trans A 36(2):357–369. doi:10.1007/s11661-005-0308-8

Driver JH, Engler O (2004) Design of aluminum rolling processes for foil, sheet, and plate. In: Xie L, Funatani K, Totten GE (eds) Handbook of metallurgical process design, 1st edn. Marcel Dekker, New York, pp 69–114

The Aluminum Association (2007) Rolling aluminum: from the mine through the mill, 3rd edn. The Aluminum Association, Arlington

Pereira P (2010) Influência da anisotropia gerada por laminação sobre a medição de tensões por ultrassom em ligas de alumínio 7050. Dissertation, Universidade Estadual de Campinas

Santos AA, Bray DE (2000) Ultrasonic stress measurement using PC based and commercial flaw detectors. Rev Sci Instrum 71(9):3464–3469. doi:10.1063/1.1287339

Proakis J, Manolakis D (1996) Digital signal processing principles, algorithms and applications. Prentice Hall, Boston

Zhang H, He Q, Yan Y (2008) A new nondestructive technique for measuring pressure in vessels by surface waves. Appl Acoust 69:891–900. doi:10.1016/j.apacoust.2007.05.011

Acknowledgments

The authors would like to thank the University of Campinas–Unicamp and the Coordenação de Aperfeiçoamento de Pessoal do Ensino Superior–CAPES.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pereira, P., Santos, A.A. Influence of Anisotropy Generated by Rolling on the Stress Measurement by Ultrasound in 7050 T7451 Aluminum. Exp Mech 53, 415–425 (2013). https://doi.org/10.1007/s11340-012-9647-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-012-9647-8